4. ASSEMBLY

4.1. Assemble the two-piece handle, using the bolt provided.

4.2. Insert the handle into the socket, taking care to ensure that the square

indentation at the base of the handle fits correctly over the square

head of the central release shaft.

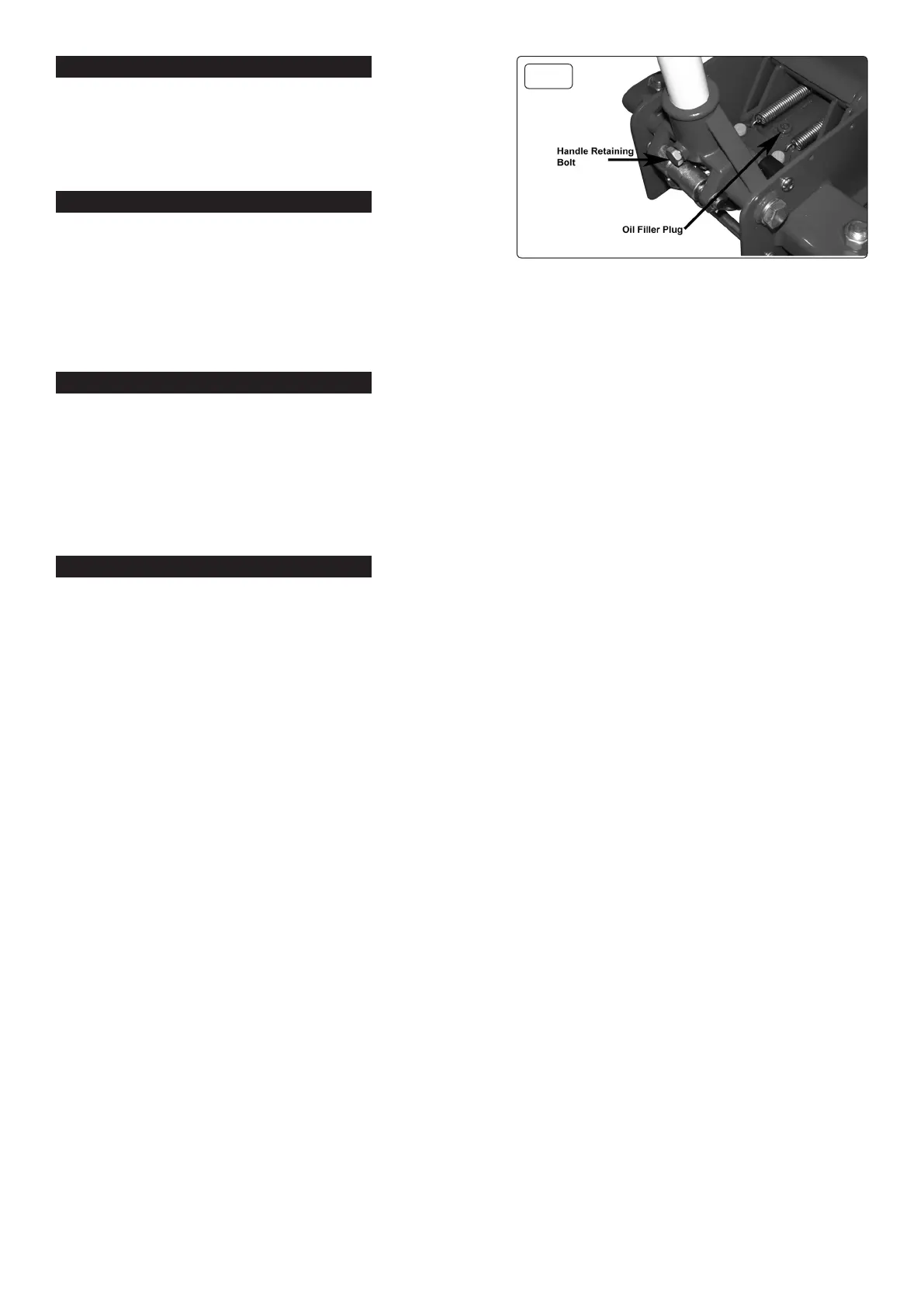

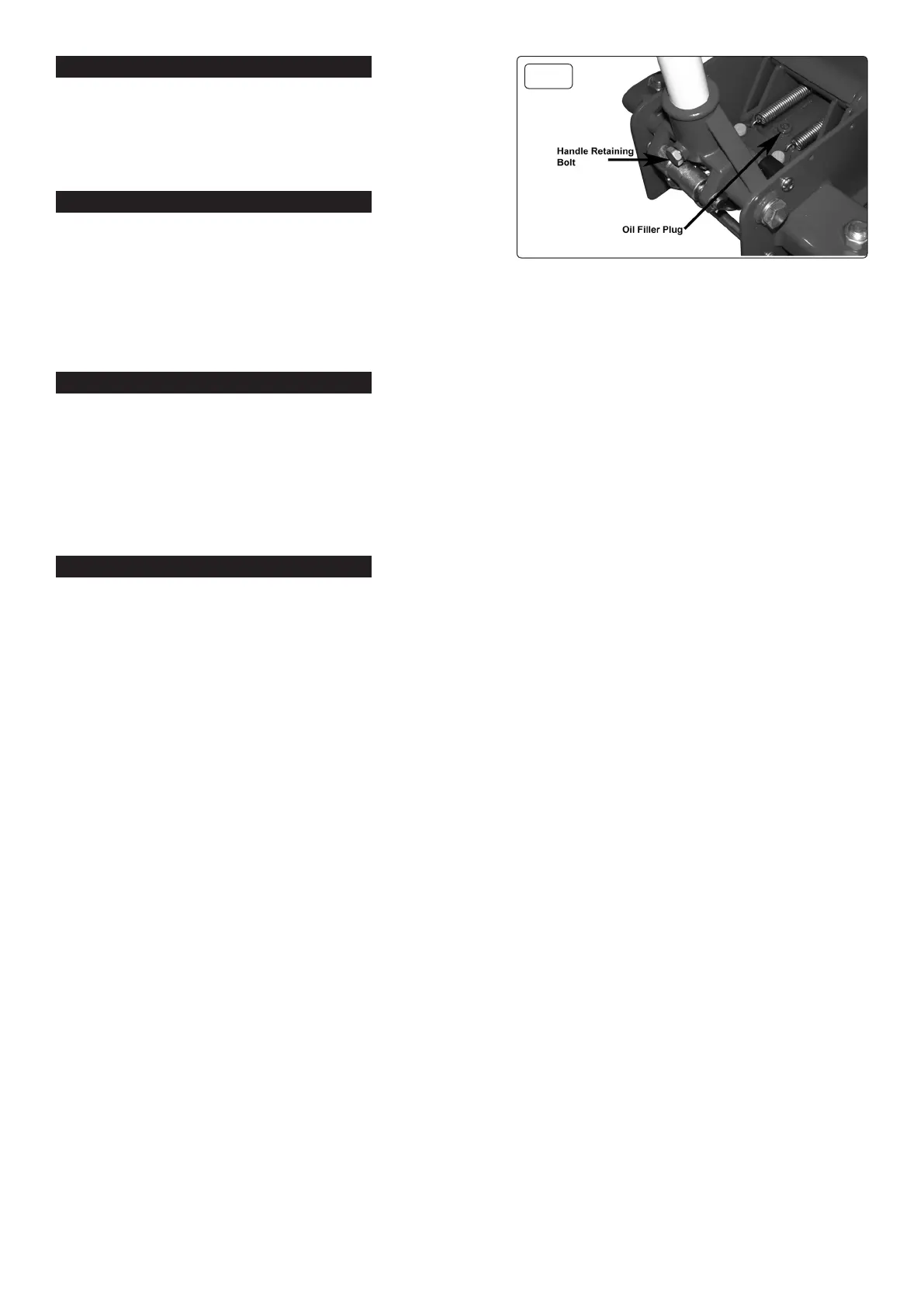

4.3. Secure the handle using the bolt provided (see fig.1).

DO NOT over-tighten.

5. BEFORE USE

5.1. Check the oil level

5.1.1. Ensure the jack is resting on level ground and that the ram is fully

retracted. Open the release valve by turning the handle anticlockwise.

5.1.2. Remove the cover plate by unscrewing the four screws.

5.1.3. Remove the filler plug with an 8mm hex key (see fig.1) The oil level should be level with the bottom of the hole.

5.1.4. If necessary, top up with hydraulic oil. Use only Sealey hydraulic jack oil (see your authorised Sealey stockist). Refit filler plug.

5.1.5. Pump the handle 20-30 times to purge the hydraulic system.

5.1.6. Close the release valve by turning the handle clockwise.

5.1.7. Remove the filler plug before pumping the jack up to its full height. Now reinstall the filler plug and replace the cover plate.

6. OPERATION

6.1. Lifting

6.1.1. When raising a vehicle, be sure to set the parking brake and chock the wheels. Perform jacking operations only on solid ground

(e.g: concrete), free from spillages and debris.

6.1.2. Position the lifting saddle of the jack under the desired lifting point (check vehicle manufacturer’s recommendations).

6.1.3. The Super Rocket Lift will raise the saddle rapidly to the vehicle lifting point with the minimum of handle strokes.

6.2. Lowering

6.2.1. Before lowering the jack, be sure that the area beneath the vehicle is clear of any persons/obstructions.

6.2.2. Open the release valve SLOWLY by turning the handle anticlockwise. When the lifting arm is in its lowest position, remove the jack from

under the vehicle.

7. MAINTENANCE

7.1. When the jack is not in use, keep the ram fully retracted and the release valve closed.

7.2. Clean the jack regularly and oil/grease all pivoting sections every 3 months (more often if using jack in extremely dry/dusty conditions).

7.3. Check the oil level frequently (see section 5.1.).

7.4. Check the piston and piston rod periodically for signs of rust/corrosion.

7.5. Should you suspect the jack to be damaged or in any way unsafe, remove from service immediately and contact your authorised Sealey

stockist for advice and repairs.

At the end of the jack’s serviceable life, drain the oil from it and dispose of according to local authority guidelines.

Owing to their size and weight, hydraulic products should ideally be repaired by local service agents. We have service / repair agents in

most parts of the UK. Before returning your product please call our technical helpline on 01284 757505 for advice and troubleshooting

guidance.

If the jack is under guarantee please contact your stockist..

g.1

3015CXDHV Issue:1 - 10/04/18

Original Language Version© Jack Sealey Limited

Loading...

Loading...