Searey LSA – Pilot’s Operating Handbook Version 5.0, Revision 8

51

7.3 FLIGHT CONTROLS

This section details the aircraft’s flight controls and control surfaces. All

control surfaces are constructed from aluminum tube and covered with

Poly-Fiber fabric. The control surfaces are assembled by bolting and/or

riveting aluminum tubes together using AN hardware. In several locations,

the tubes are separated and supported by using plastic saddles and/or

spacers at joints. The control surfaces all have similar hinges. These are

small stainless steel ‘U’ brackets that are bolted to the surfaces to be

hinged.

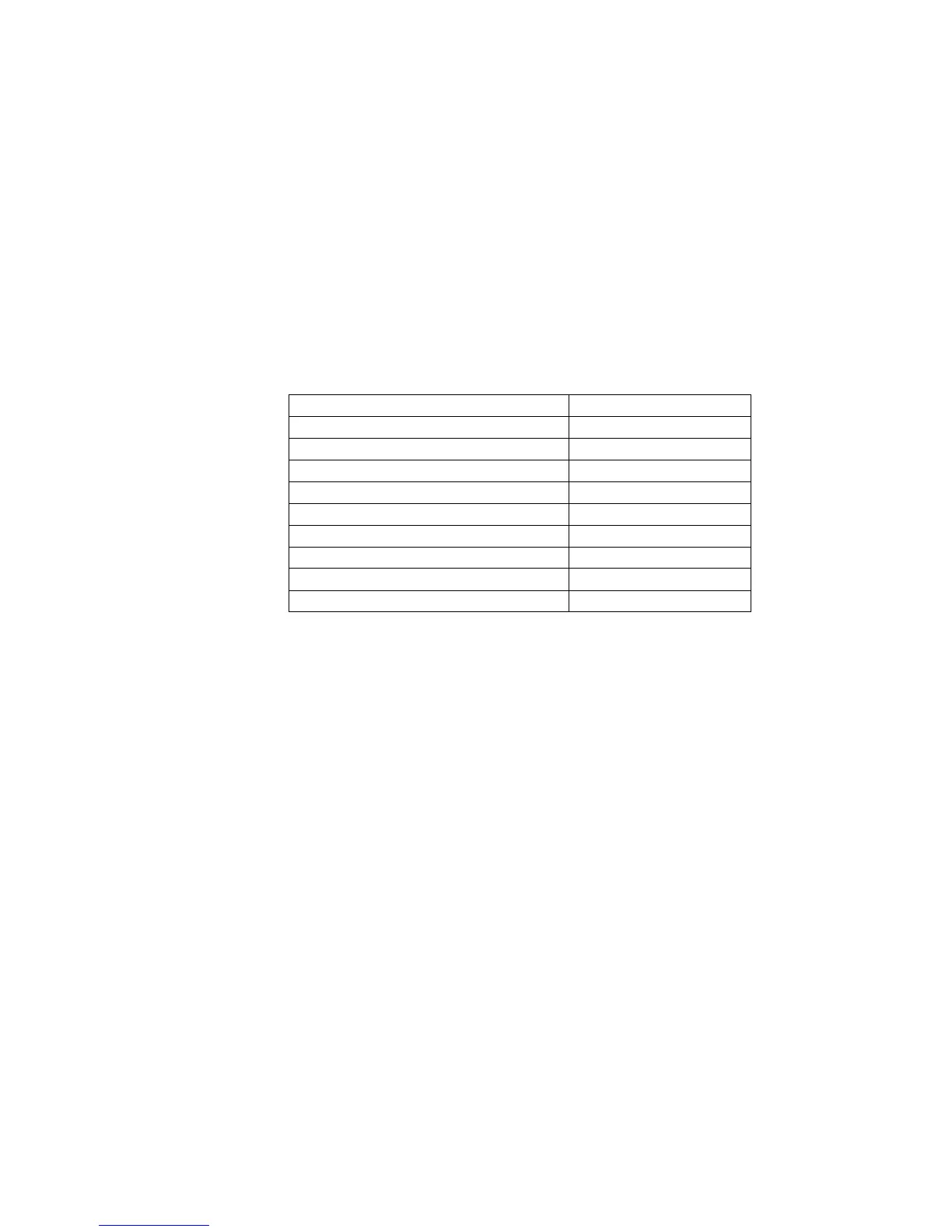

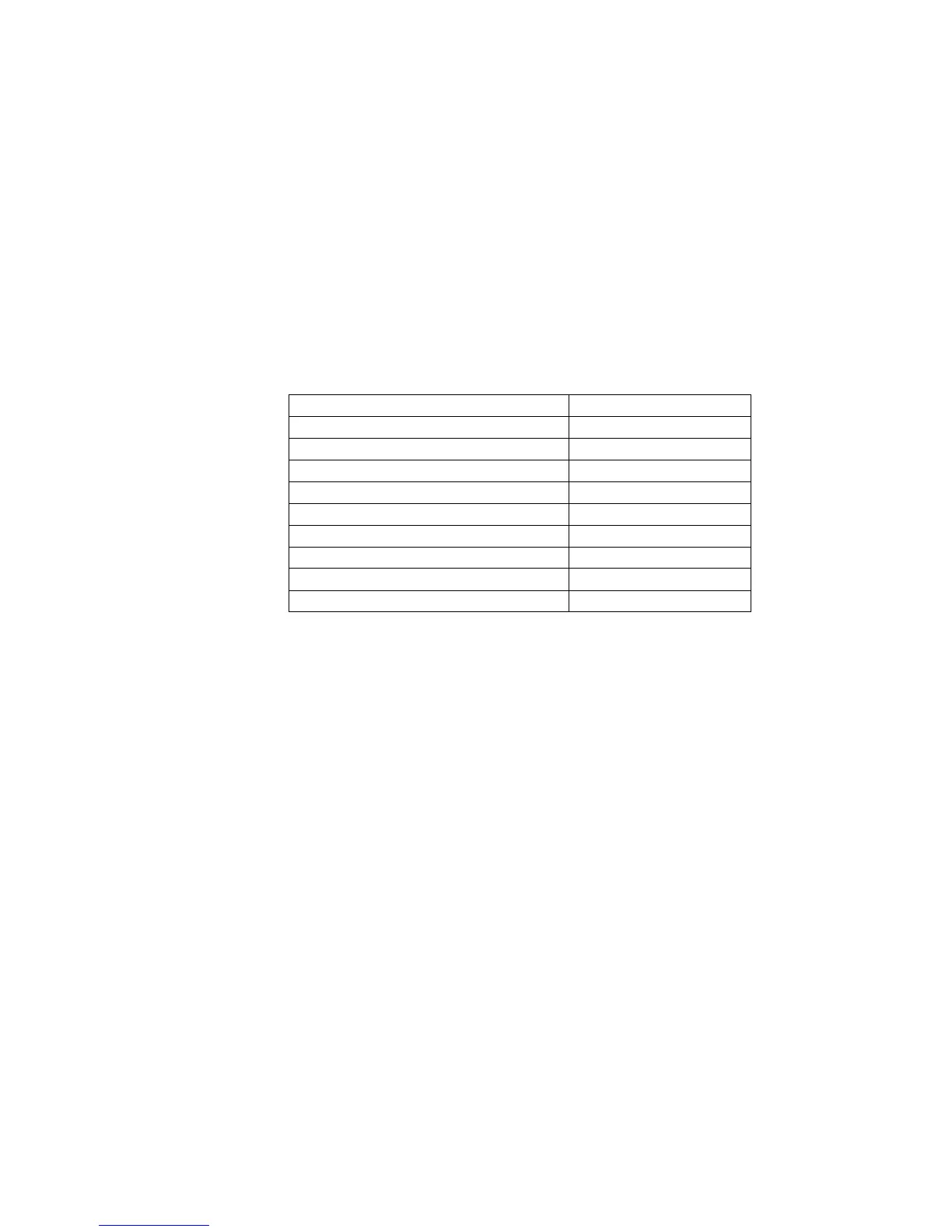

7.3.1 FLIGHT CONTROLS – SURFACE DEFLECTIONS

The control surface deflections are as follows:

Flaps - Neutral Flap Position

Flaps - First Flap Position

Flaps - Second Flap Position

Flaps - Third Flap Position

Flaps - Neutral Flap Position

Flaps - First Flap Position

Flaps - Second Flap Position

Note: All control surface deflection tolerances are +/- 2.

7.3.2 WING FLAPS

The electric flaps are actuated by an actuator that is located above the

pilot’s right shoulder. This lever actuates the flaps by a pushrod system.

A single pushrod connects the lever to an idler near the rear wing spar

attachment. This idler is then connected to the flaps by two pushrods,

one to each side of the fuselage. The idler acts as an interconnection

between the flaps.

Extension of the wing flaps is achieved by using the electric flap controller

located on the center console.

7.3.3 AILERONS

The aileron system is a combination of a bell crank, torque tubes and

seven push-pull rods.

A push rod runs from the lower end of each control stick to a central bell

crank, located under and between the two seats. A rod connects this

forward bell crank to a second rear bell crank which in turn connects to a

Loading...

Loading...