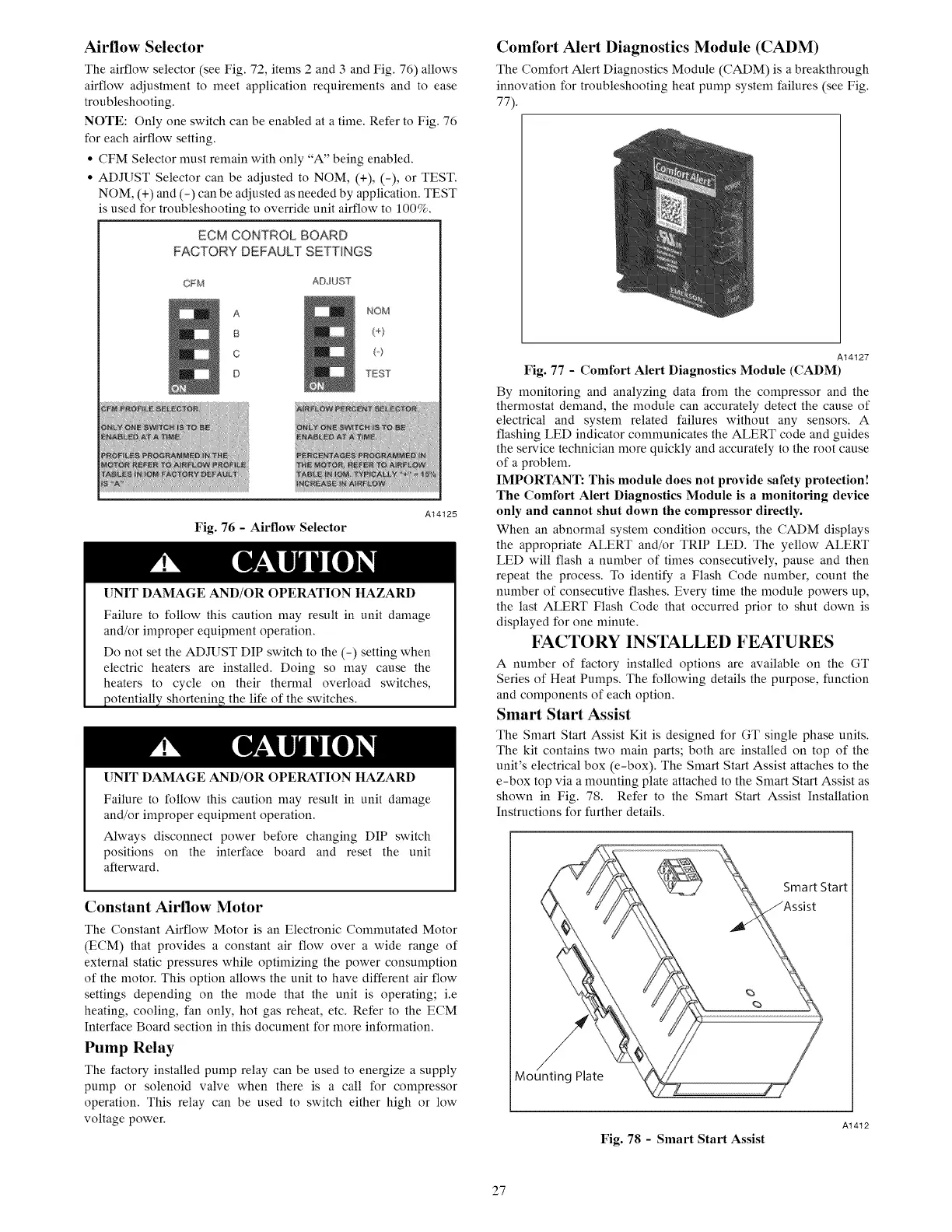

Airflow Selector

The airflow selector (see Fig. 72, items 2 and 3 and Fig. 76) allows

airflow adjustment to meet application requirements and to ease

troubleshooting.

NOTE: Only one switch can be enabled at a time. Refer to Fig. 76

for each airflow setting.

• CFM Selector must remain with only "A" being enabled.

• ADJUST Selector can be adjusted to NOM, (+), (-), or TEST.

NOM, (+) and (-) can be adjusted as needed by application. TEST

is used for troubleshooting to override unit airflow to 100%.

ECM CONTROL BOARD

FACTORY DEFAUU SETTINGS

CFM

ADJUST

A

B

C

D

NOM

(+)

(o)

TEST

Fig. 76 - Airflow Selector

A14125

UNIT DAMAGE AND/OR OPERATION HAZARD

Failure to follow this caution may result in unit damage

and/or improper equipment operation.

Do not set the ADJUST DIP switch to the (-) setting when

electric heaters are installed. Doing so may cause the

heaters to cycle on their thermal overload switches,

potentially shortening the life of the switches.

UNIT DAMAGE AND/OR OPERATION HAZARD

Failure to follow this caution may result in unit damage

and/or improper equipment operation.

Always disconnect power before changing DIP switch

positions on the interface board and reset the unit

afterward.

Constant Airflow Motor

The Constant Airflow Motor is an Electronic Conmmtated Motor

(ECM) that provides a constant air flow over a wide range of

external static pressures while optinfizing the power consumption

of the motor. This option allows the unit to have different air flow

settings depending on the mode that the unit is operating; i.e

heating, cooling, fan only, hot gas reheat, etc. Refer to the ECM

Interface Board section in this document for more information.

Pump Relay

The factory installed pump relay can be used to energize a supply

pump or solenoid valve when there is a call for compressor

operation. This relay can be used to switch either high or low

voltage power.

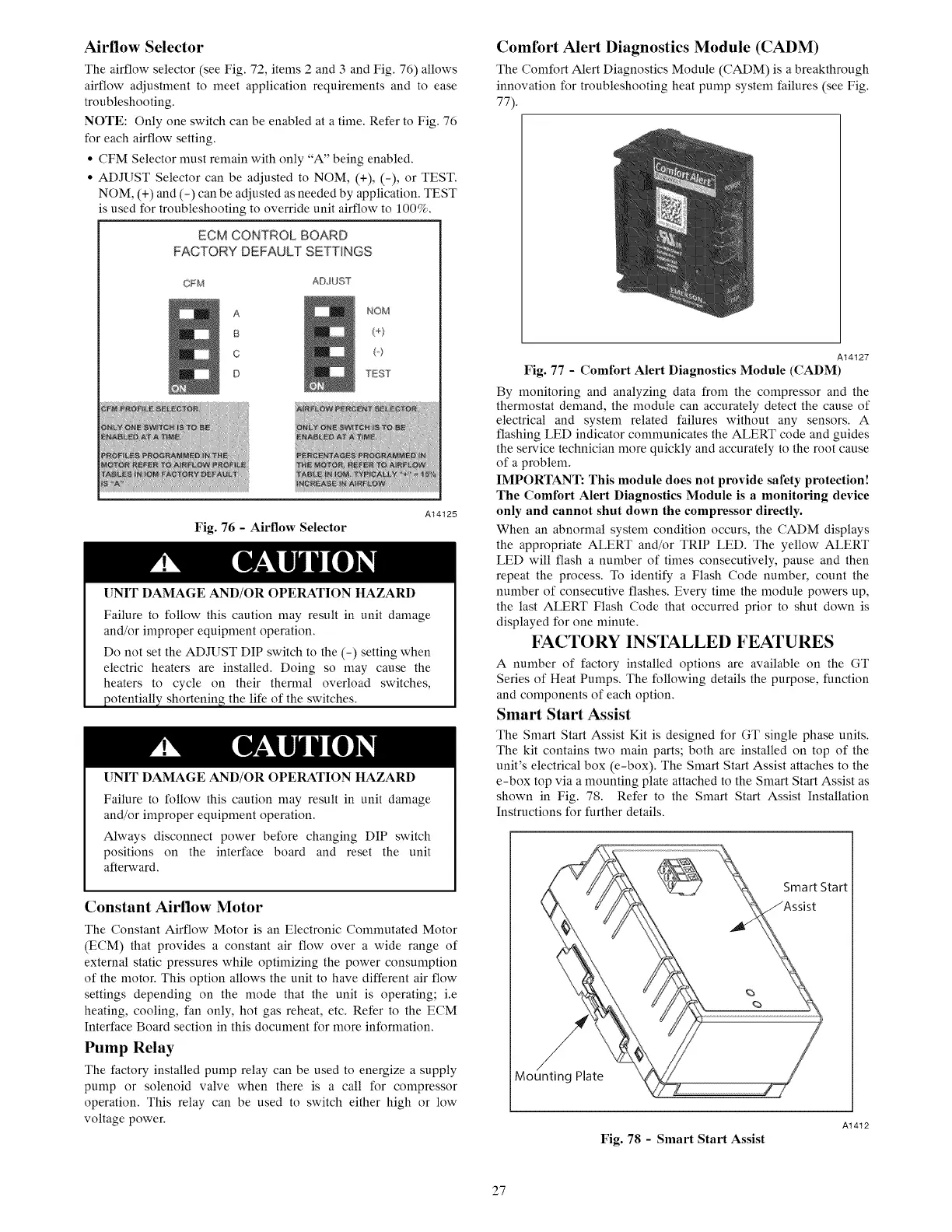

Comfort Alert Diagnostics Module (CADM)

The Comfort Alert Diagnostics Module (CADM) is a breakthrough

innovation for troubleshooting heat pump system failures (see Fig.

77).

A14127

Fig. 77 - Comfort Alert Diagnostics Module (CADM)

By monitoring and analyzing data from the compressor and the

thermostat demand, the module can accurately detect the cause of

electrical and system related failures without any sensors. A

flashing LED indicator conmmnicates the ALERT code and guides

the service technician more quickly and accurately to the root cause

of a problem.

IMPORTANT: This module does not provide safety protection!

The Comfort Alert Diagnostics Module is a monitoring device

only and cannot shut down the compressor directly.

When an abnormal system condition occurs, the CADM displays

the appropriate ALERT and/or TRIP LED. The yellow ALERT

LED will flash a number of times consecutively, pause and then

repeat the process. To identify a Flash Code number, count the

number of consecutive flashes. Every time the module powers up,

the last ALERT Flash Code that occurred prior to shut down is

displayed for one nfinute.

FACTORY INSTALLED FEATURES

A number of factory installed options are available on the GT

Series of Heat Pumps. The following details the purpose, function

and components of each option.

Smart Start Assist

The Smart Start Assist Kit is designed for GT single phase units.

The kit contains two main parts; both are installed on top of the

unit's electrical box (e-box). The Smart Start Assist attaches to the

e-box top via a mounting plate attached to the Smart Start Assist as

shown in Fig. 78. Refer to the Smart Start Assist Installation

Instructions for further details.

Smart Start

Mounting Plate

Fig. 78 - Smart Start Assist

A1412

27

Loading...

Loading...