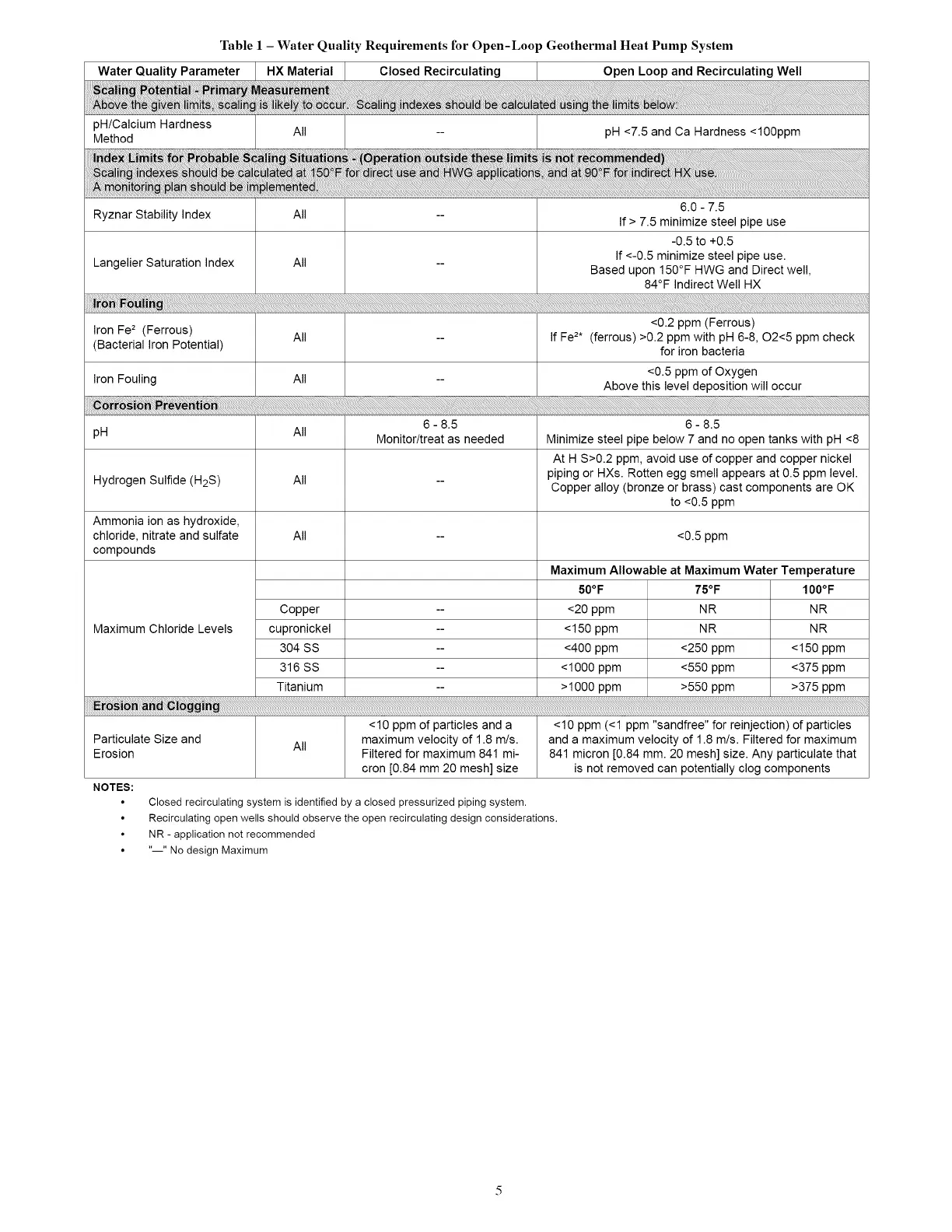

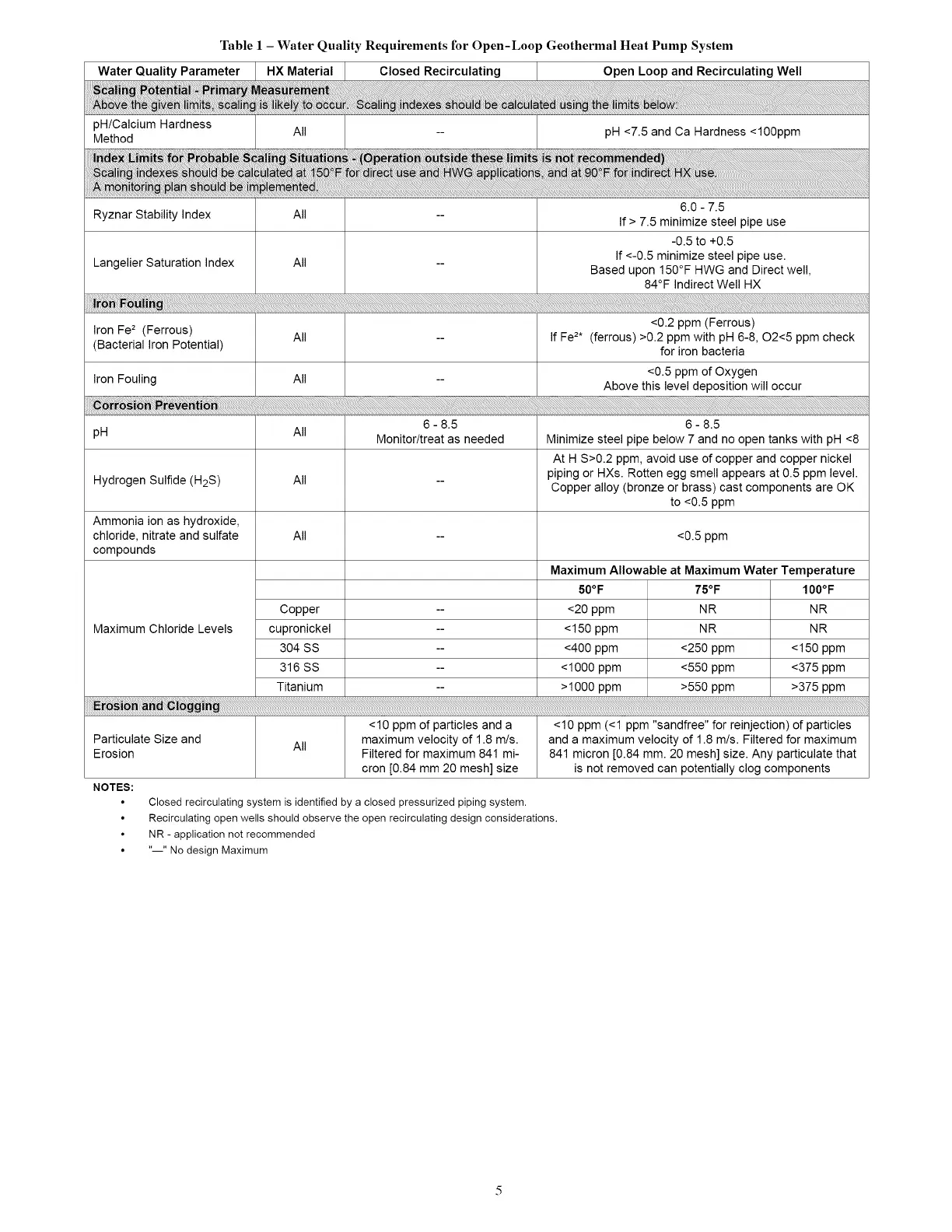

Table 1 - Water Quality Requirements for Open-Loop Geothermal Heat Pump System

Parameter HX Material Closed Recirculating Open Loop and Recirculating Well

pH/Calcium Hardness

All pH <7.5 and Ca Hardness <100ppm

Method

6.0 - 7.5

Ryznar Stability Index All --

If > 7.5 minimize steel pipe use

-0.5 to +0.5

If <-0.5 minimize steel pipe use.

Langelier Saturation Index All --

Based upon 150°F HWG and Direct well,

84°F Indirect Well HX

<0.2 ppm (Ferrous)

Iron Fe2 (Ferrous) All -- If Fe2. (ferrous) >0.2 ppm with pH 6-8, 02<5 ppm check

(Bacterial Iron Potential) for iron bacteria

<0.5 ppm of Oxygen

Iron Fouling All --

Above this level deposition will occur

6 - 8.5 6 - 8.5

pH All

Monitor/treat as needed Minimize steel pipe below 7 and no open tanks with pH <8

At H S>0.2 ppm, avoid use of copper and copper nickel

piping or HXs. Rotten egg smell appears at 0.5 ppm level.

Hydrogen Sulfide (H2S) All --

Copper alloy (bronze or brass) cast components are OK

to <0.5 ppm

Ammonia ion as hydroxide,

chloride, nitrate and sulfate All -- <0.5 ppm

compounds

Maximum Allowable at Maximum Water Temperature

50°F 75°F 100°F

Copper -- <20 ppm NR NR

Maximum Chloride Levels cupronickel -- <150 ppm NR NR

304 SS -- <400 ppm <250 ppm <150 ppm

316 SS -- <1000 ppm <550 ppm <375 ppm

Titanium -- >1000 ppm >550 ppm >375 ppm

_i _ ........

<10 ppm of particles and a <10 ppm (<1 ppm "sandfree" for reinjection) of particles

Particulate Size and All maximum velocity of 1.8 m/s. and a maximum velocity of 1.8 m/s. Filtered for maximum

Erosion Filtered for maximum 841 mi- 841 micron [0.84 mm. 20 mesh] size. Any particulate that

cron [0.84 mm 20 mesh] size is not removed can potentially clog components

NOTES:

Closed recirculating system is identified by a closed pressurized piping system.

Recirculating open wells should observe the open recirculating design considerations.

NR - application not recommended

"--" No design Maximum

Loading...

Loading...