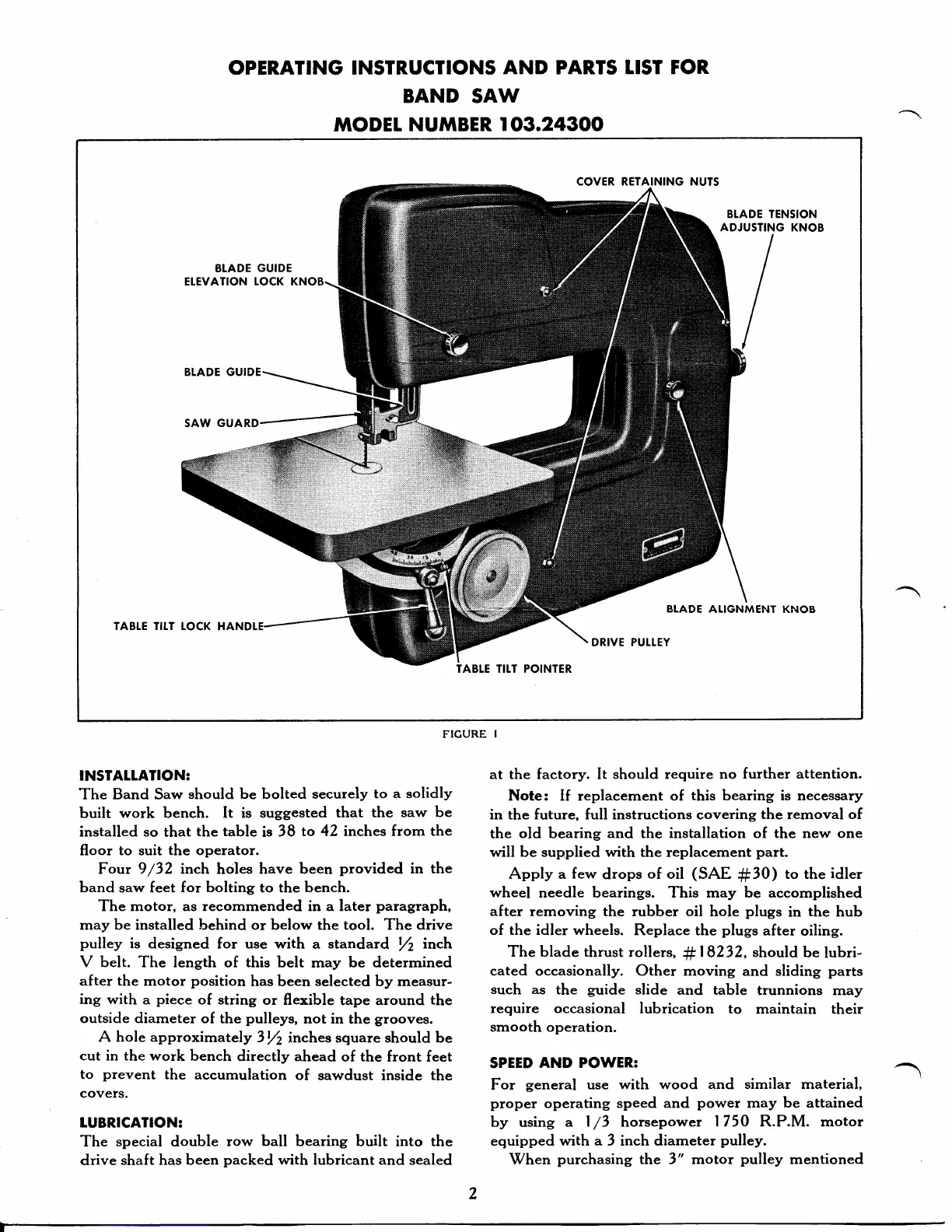

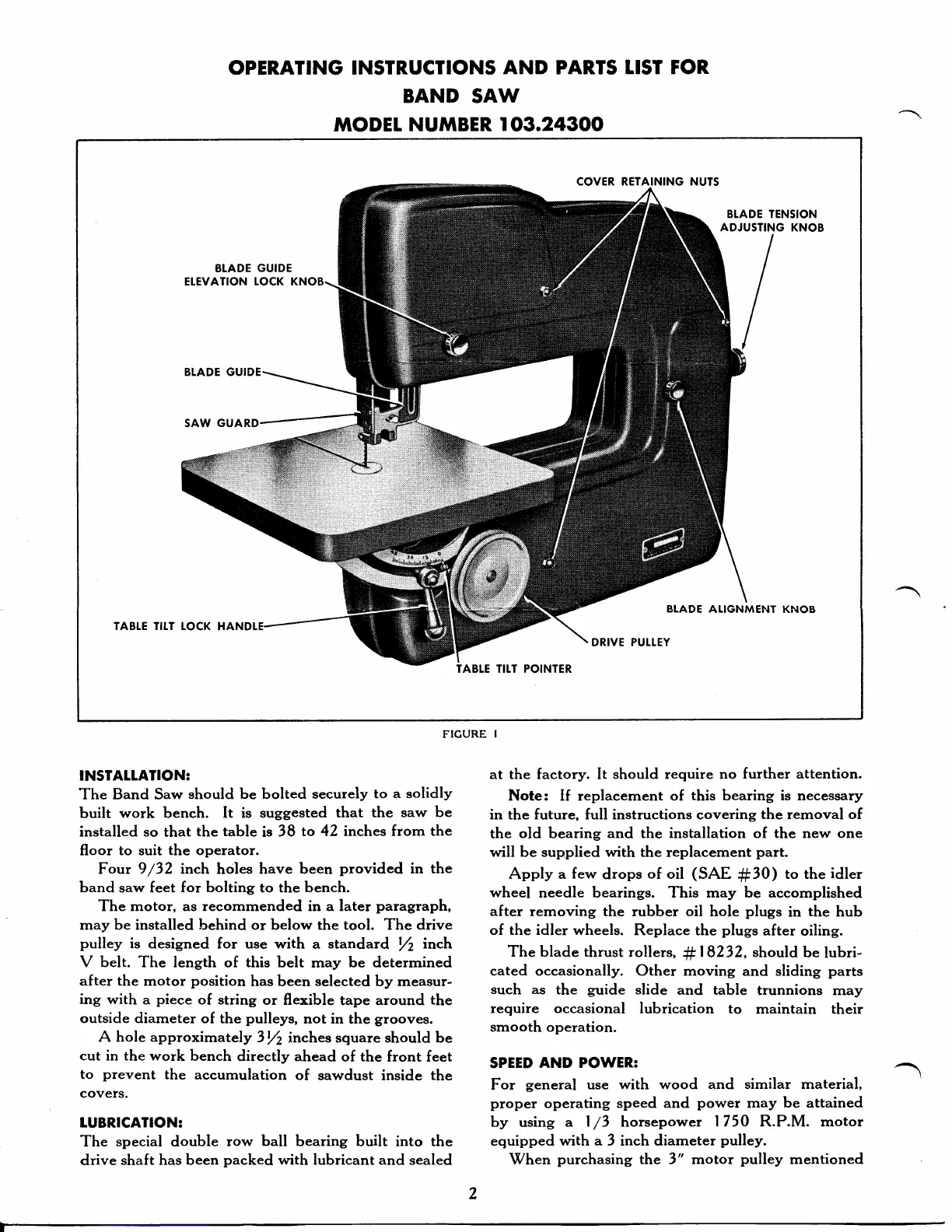

OPERATING

INSTRUCTIONS

AND PAR,TS

LIST FOR.

BAND

SAW

tnoDEt

NUMBER I

03.24300

COVER RETAINING NUTS

BTADE GUIDE

SAW GUARD

TABTE TIIT IOCK

HAN

TABLE TIIT POINTER

FIGURE

I

TNSTATLATION:

The Band Saw

should be bolted

securely

to

a

solidly

built

work bench. It

is suggested

that the

saw be

installed

so

that

the table

is

38

to 42 inches

from the

floor to suit

the operator.

Four

9

/32

inch

holes

have been

provided

in the

band saw feet for bolting to the

bench.

The

motor, as recommended in a later

paragraph,

may be installed behind or below

the tool. The

drive

pulley

is

designed for use with

a

standard

Yz

inch

V belt.

The length of this belt

may

be determined

after the

motor

position

has been

selected

by measur-

ing

with

a

piece

of string

or flexible

tape around

the

outside diameter

of the

pulleys,

not in

the

grooves.

A hole approximately

3t/2

inches sguare should

be

cut in the work

bench

directly ahead

of the

front feet

::#::.nt

the

accumulation

of

sawdust

inside

the

lUBRICATION:

The

special double

row

ball

bearing built into the

drive shaft

has been

packed

with lubricant

and

sealed

at the factory. It

should require no further

attention.

Note: If replacement of

this bearing is necessary

in the future, full instructions covering

the removal of

the old bearing and the

installation

of

the

new

one

will be supplied with the replacement

part.

Apply a

few

drops

of oil

(SAE

#30)

to the

idler

wheel

needle bearings. This may be accomplished

after

removing the rubber

oil

hole

plugs

in

the

hub

of the idler

wheels. Replace

the

plugs

after

oiling.

The

blade

thrust

rollers,

#18232,

should

be

lubri-

cated occasionally. Other

moving and sliding

parts

such as

the

guide

slide

and table

trunnions

rnay

require occasional lubrication

to

maintain their

smooth

operation.

SPEED

AND POWER:

For

general

use

with wood and

similar material,

proper

operating speed

and

power

may

be

attained

by using

a |

/3

horsepower

1750 R.P.M. motor

equipped

with

a

3 inch diameter

pulley.

When

purchasing

the 3" motor

pulley

mentioned

Loading...

Loading...