508.366.1488 | www.semshred.com

11. Knife Grinding (Sharpening)

When the disintegrator knife edges become dull, they may be sent to Security Engineered Machinery or they may

be sharpened by a capable machine shop. It is important that the rotor knives and bed knives be sharpened as

a set to maintain proper tolerances for effective knife settings.

If knives are badly nicked, the machine shop should not try to eliminate the entire nick so as to conserve the edge and

prolong knife life. The knives will function properly with nicks after sharpening, as long as 75% of the cutting edge is

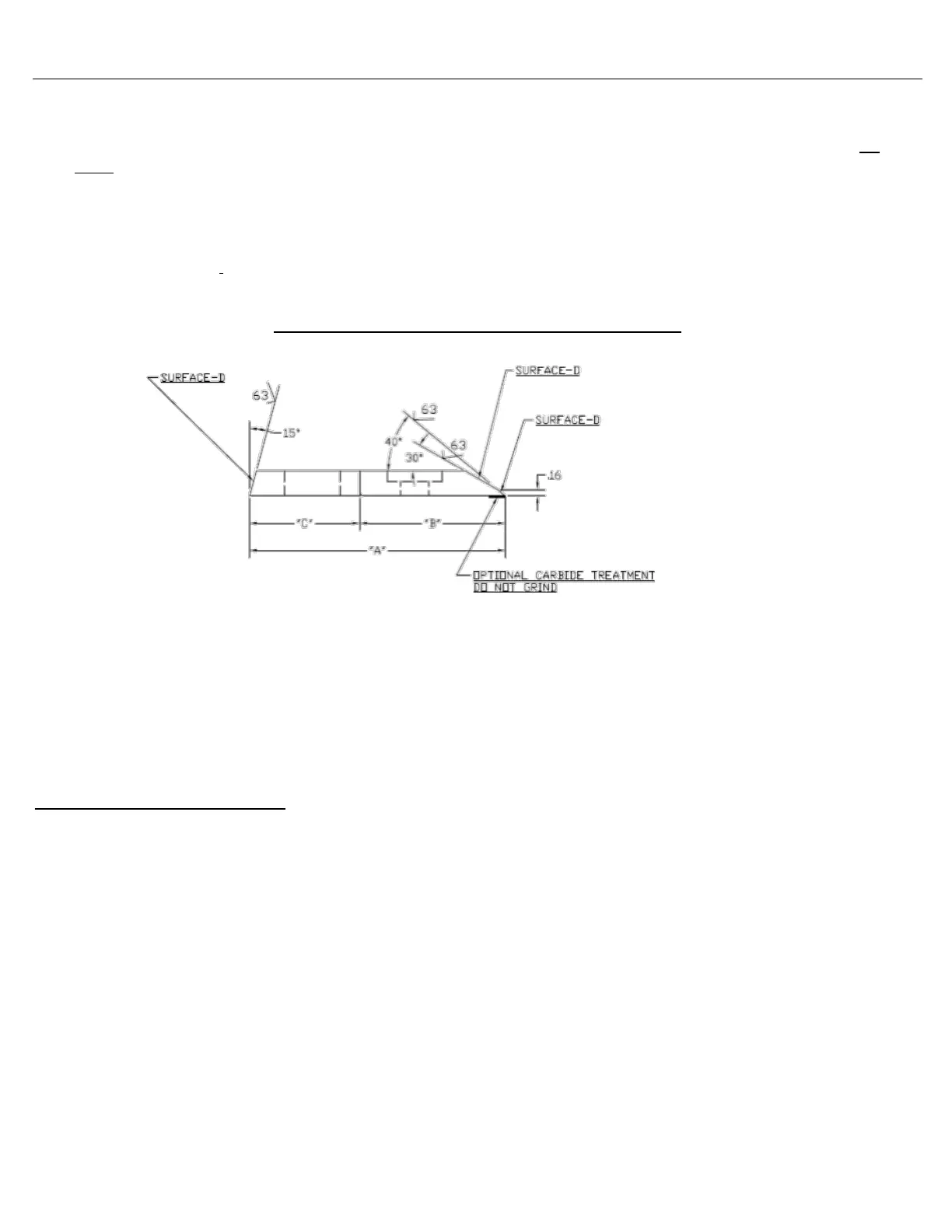

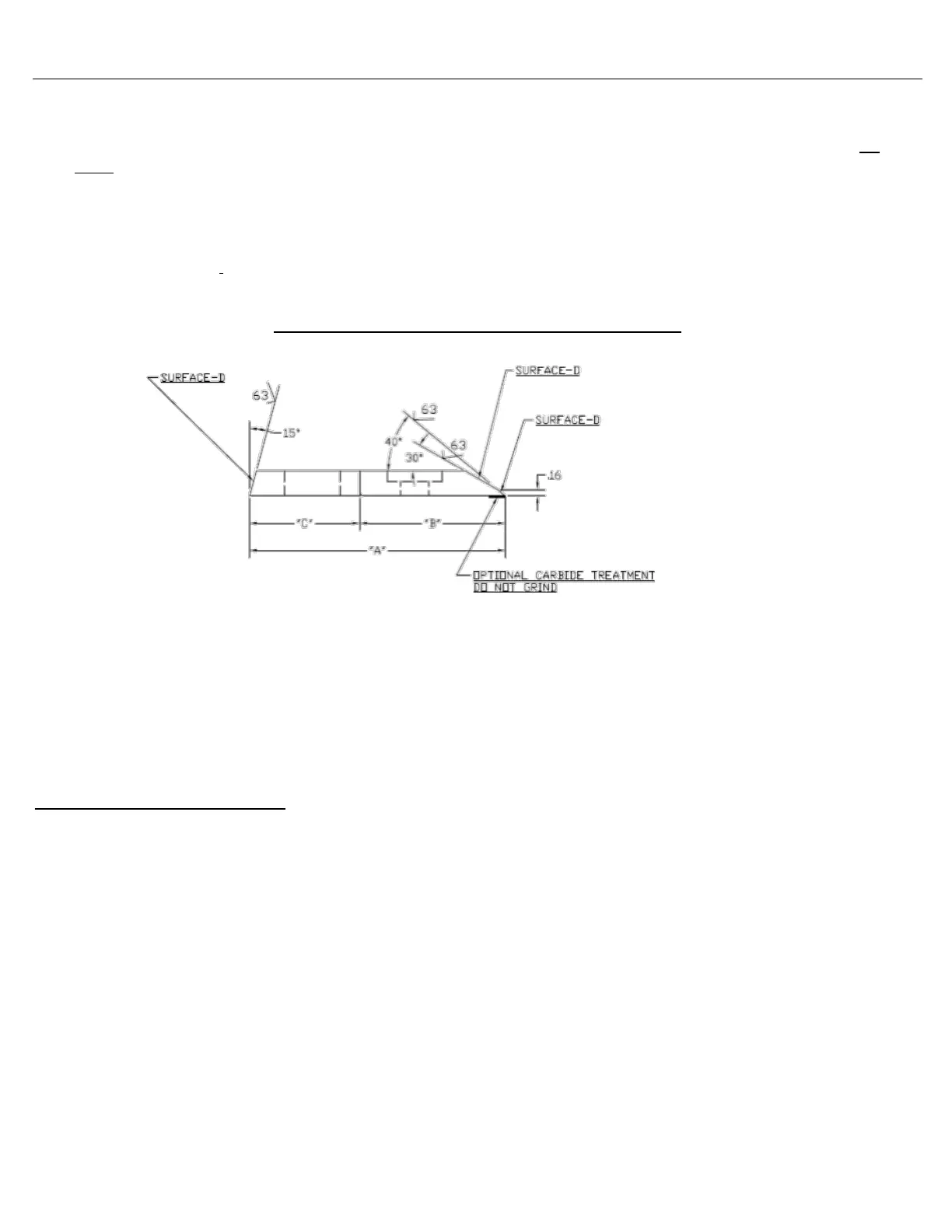

effective. Reference below Figure A, Figure B and Figure C for the following rotor and bed knife set up. NOTE: Only grind

surfaces marked "D".

Standard Form Rotor Knife with Standard Form Bed Knife

NOTES ON KNIFE GRINDING:

After regrinding a number of times, the knives must be checked to be sure that there will be adjustment left in the bed knives.

The general rule is to place a rotor knife and bed knife back to back as shown in the image above and measure the total

distance, dimension "A".

Refer to "A" dimension chart per machine model number blow.

Distance Dimension “A” – Minimum

Model 1012 = 4-3/4” Model 22 & 22/5 = 5-3/4”

Model 1012/5 = 4-3/8” Model 23 & 23/5 = 5-3/4”

Note: If dimension "A" is close to minimum, a new set of knives should be ordered from SEM. Please contact SEM customer

service department.

Dimension B: Bed knives tolerance must be held alike and parallel in sets within .010".

Dimension C: Rotor knives tolerance must be held alike and parallel in sets within .002”.

Loading...

Loading...