9.1 Supply line

Keep the supply line as short as possible and lay it in such a

way that only low acceleration pressures or pressure losses

develop.

Avoid contamination and precipitations.

9.2 Return line

Keep the return line as short as possible and lay it downgrade.

Elbows are to be preferred to angles. The return line must not

be under pressure, provide for a free outlet (see Fig. 06).

Make sure that there are no shut-off valves or check valves in

the return line.

If the return line is linked to the suction line of the pump, no

check valves may be installed in the suction line.

Lay the lines in such a way that precipitations are excluded.

10 Start-up

During commissioning, observe the following:

• Open all shut-off valves that are mounted in the suction

line and pressure line (except for flushing and discharge

fittings).

• Start pump / system.

• Slowly increase the delivery rate via the stroke frequency

or stroke length adjustment to the maximum setting (see

Fig. 08).

Dosing pump

Stroke length

adjustment

Fig. 08

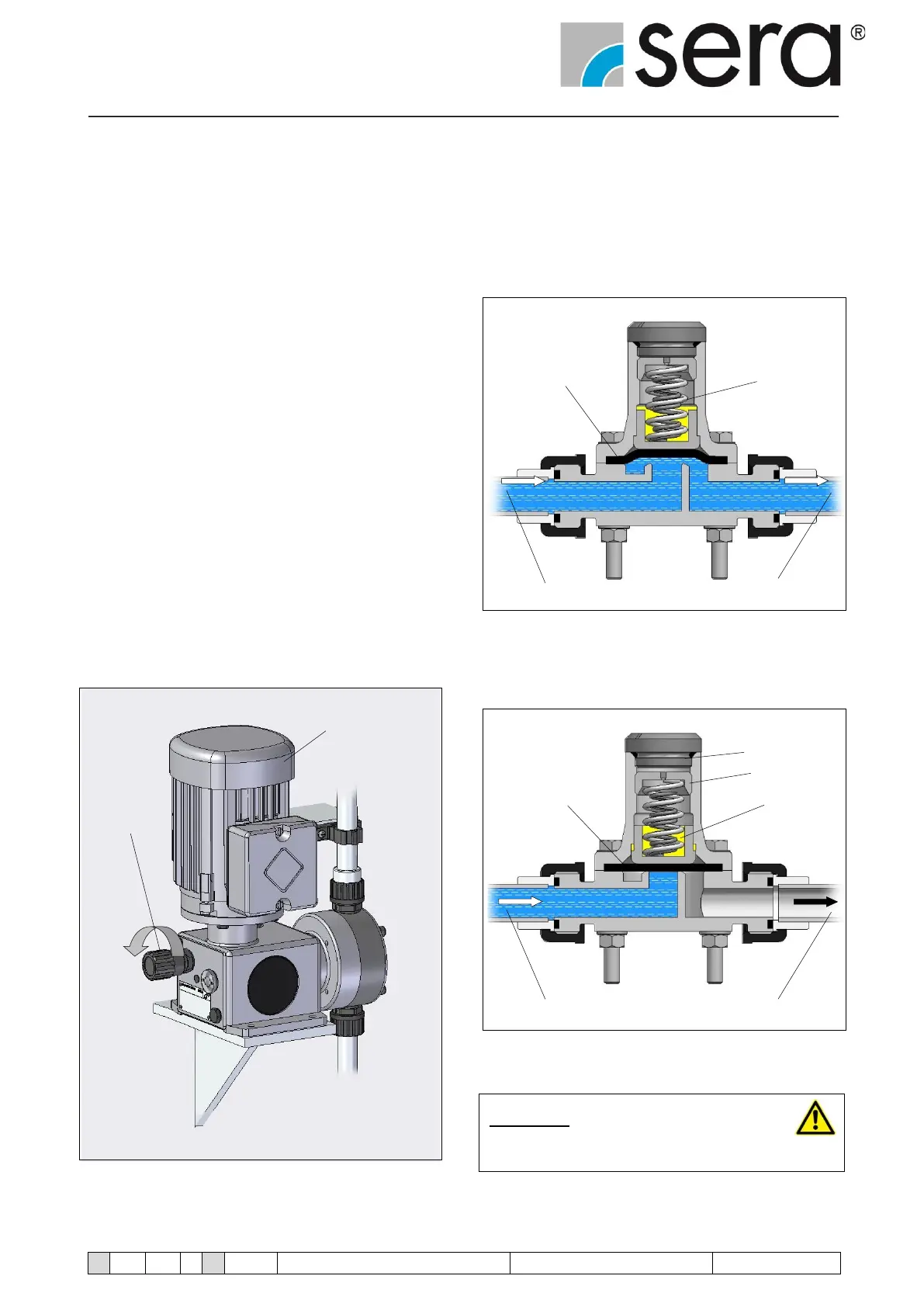

The diaphragm closes the inlet channel by the pressure spring

initial tension (= set pressure of the valve in bar).

If the medium at the diaphragm reaches the set pressure, the

diaphragm is lifted and the medium flows in the outlet channel

(see Fig. 09).

Diaphragm Damping fluid

Inlet channel Outlet channel

Fig. 09 Operational mode

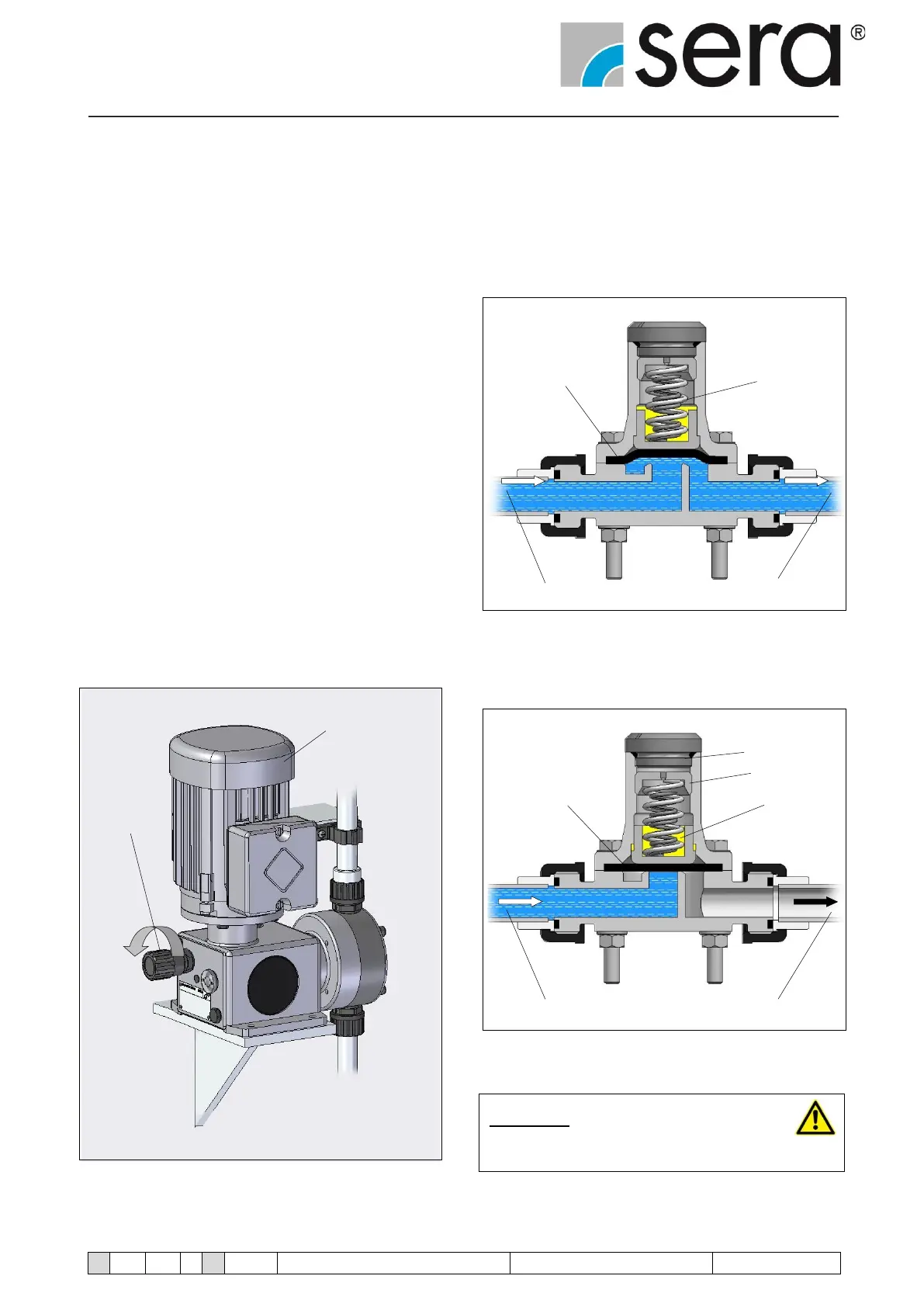

The diaphragm closes the inlet channel only when the pres-

sure of the medium drops below the set pressure (see Fig. 10).

Lid

Set screw

Diaphragm Damping fluid

Inlet channel Outlet channel

Fig. 10 Operational mode

CAUTION !

The use of damping fluid is shown of the table 07

(page 16).

Loading...

Loading...