4 Areas of application and function

sera diaphragm relief valves can be used for liquid media

without solid matters but exclusively for the intended use as

specified by the manufacturer.

sera diaphragm relief valves protect especially oscillating dis-

placement pumps which, in theory, can build up a infinitely

high pressure. If pressure lines are restricted or closed the

pressure may reach a multiple of the permissible system pres-

sure, e.g. owing to clogged lines (foreign matters, crystals) or

closed shut-off valves, clogged nozzles or filters etc.

CAUTION !

As sera diaphragm relief valves cannot reduce accelera-

tion pressure peaks with oscillating displacement pumps

an additional pulsation damper is to be provided.

CAUTION !

sera diaphragm relief valves are no safety valves as per

the requirements of the regulations for pressure systems

2014/68/EU.

CAUTION !

Do not change the setting of the relief valve!

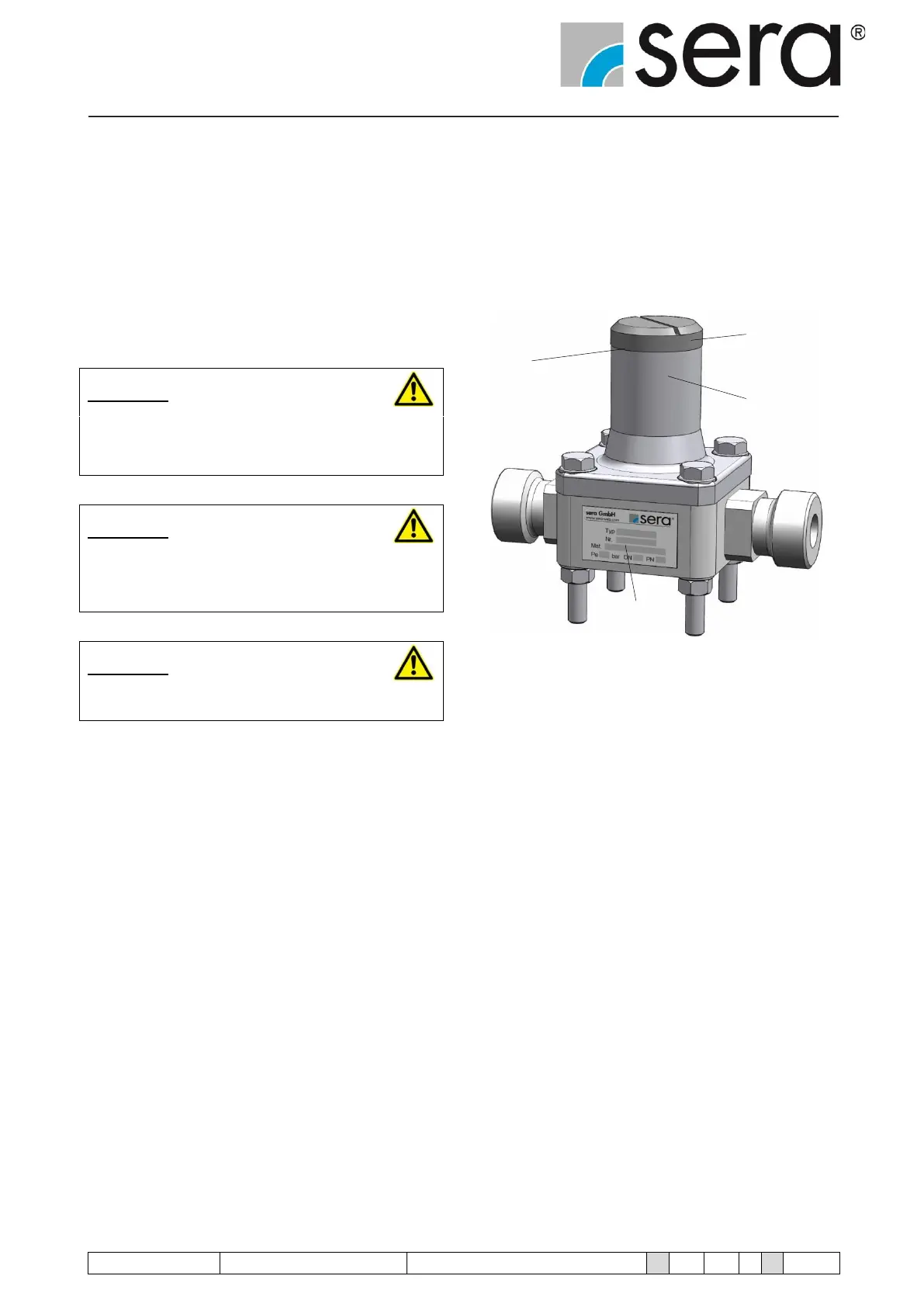

5 Test / identification

sera diaphragm relief valves are tested in our works and set to

an operative pressure.

The set pressure corresponds to the technical delivery condi-

tions which are indicated on the type plate (see Fig.

01/02/Table 01).

Lid

Seal

Cover

Type plate

Fig. 02

6 Checking the packaging at the place of

destination

On delivery, immediately check the packaging for damage.

Report any external damage immediately to the transport

company, and fill out a damage report. After the transport

company has recorded the damage, open the package and

check the contents for damage.

7 Storage

An undamaged packaging protects the unit during subsequent

storage and should only be opened when the diaphragm relief

valve is installed.

Proper storage increases the service life of the diaphragm re-

lief valve and comprises prevention of negative influences

such as heat, humidity, dust, chemicals etc.

The following storage instructions are to be observed:

• Storage place: cool, dry, dust-free and slightly ventilated

• Storage temperatures between -10°C and +45°C

• Relative air humidity not more than 50%.

If these values are exceeded, metal products should be sealed

in foil and protected from condensation water with a suitable

desiccant.

Do not store solvents, fuels, lubricants, chemicals, acids, disin-

fectants and similar in the storage room.

Loading...

Loading...