Assemble the pump in reversed order

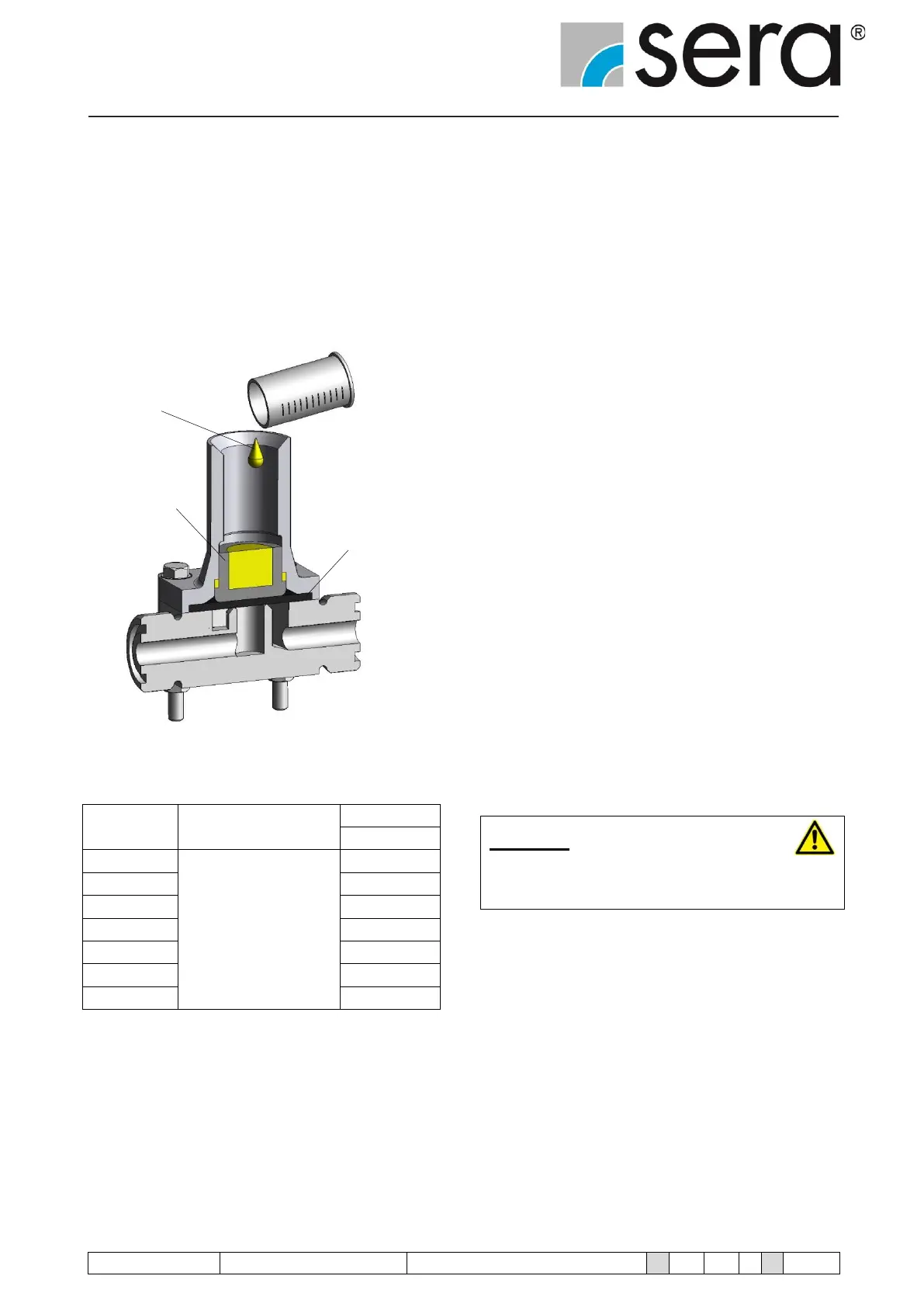

• Insert diaphragm (PTFE-foil pointing downstream) in the

recess of the cover.

• Fasten cover with screws on the valve housing.

• Fill in damping fluid (for type and quantity please see

Table 07).

Damping

fluid

Pressure disk

Diaphragm

Fig. 15

Table 07 Damping fluid

• Insert pressure spring.

• Screw in set screw up to dimension “T”.

• Screw lid in cover.

15 Shut-down

• Shut-down the pump/system and secure it against restart-

ing!

• Make sure that all pipes with diaphragm relief valves are

depressurized!

• Drain the diaphragm relief valve and the connected pipes

using drain valves!

• Remove residues of the pumped medium out of the dia-

phragm relief valve by rinsing it with a compatible deter-

gent!

• The diaphragm relief valve damper can then be removed

out of the pipe.

16 Disposal

Shut-down system. Please see “Shut-down”.

16.1 Dismantling and transport

• Remove all fluid residues, clean thoroughly, neutralize

and decontaminate.

• Package unit and ship.

16.2 Complete disposal

• Remove all fluid residues from unit.

• Drain off lubricants and dispose of according to regula-

tions!

• Dismount materials and send them to a suitable waste

disposal company!

CAUTION !

The consignor is responsible for damage caused by leak-

ing lubricants and fluids!

Loading...

Loading...