5

30

R..7, F..7, K..7, S..7, Spiroplan

®

W Gear Units – Operating Instructions

Startup

5Startup

5.1 Startup of helical-worm and Spiroplan

®

W gear units

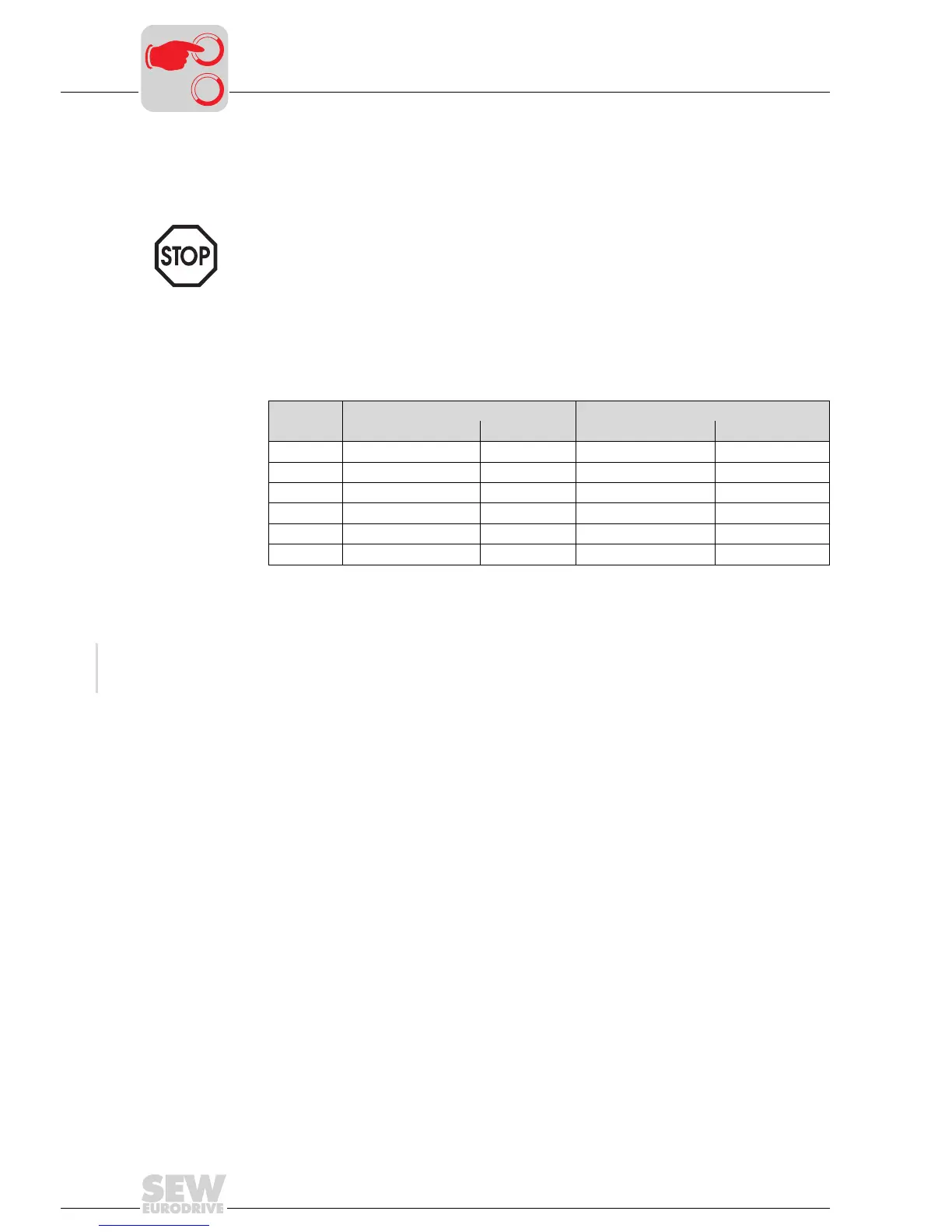

Running-in

period

Spiroplan

®

and helical-worm gear units require a running-in period of at least 24 hours

before reaching their maximum efficiency. A separate running-in period is required for

each direction of rotation if the gear unit is operated in both directions of rotation. The

table displays the average power reduction during the running-in period.

5.2 Startup of helical, parallel shaft helical and helical-bevel gear units

There are no special startup notes that have to be observed for helical gear units,

parallel shaft helical gear units and helical-bevel gear units, if the gear units have been

mounted according to the section "Mechanical Installation."

Note: The direction of rotation for the output shaft has been changed from CW to CCW

for helical-worm gear units S..7 series compared to the S..2 series. Switch two motor

feeder cables to change the direction of rotation.

No. of

starts

Helical-worm Spiroplan

®

power reduction i range power reduction i range

1 start approx. 12% app. 50...280 approx. 15% approx. 40...75

2 starts approx. 6% app. 20...75 approx. 10% approx. 20...30

3 starts approx. 3% app. 20...90 approx. 8% approx. 15

4 starts - - approx. 8% approx. 10

5 starts approx. 3% app. 6...25 approx. 5% approx. 8

6 starts approx. 2% app. 7...25 - -

Loading...

Loading...