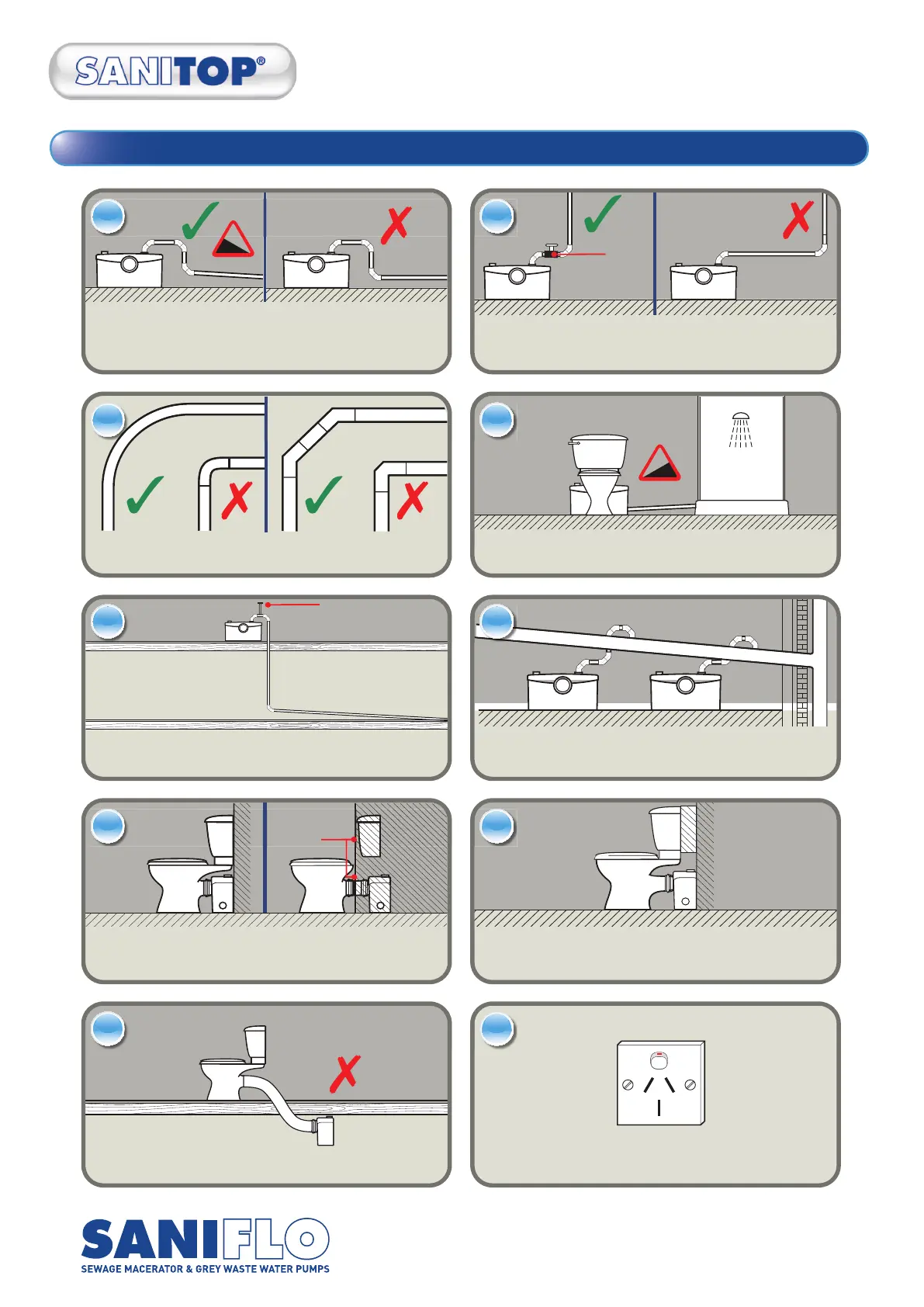

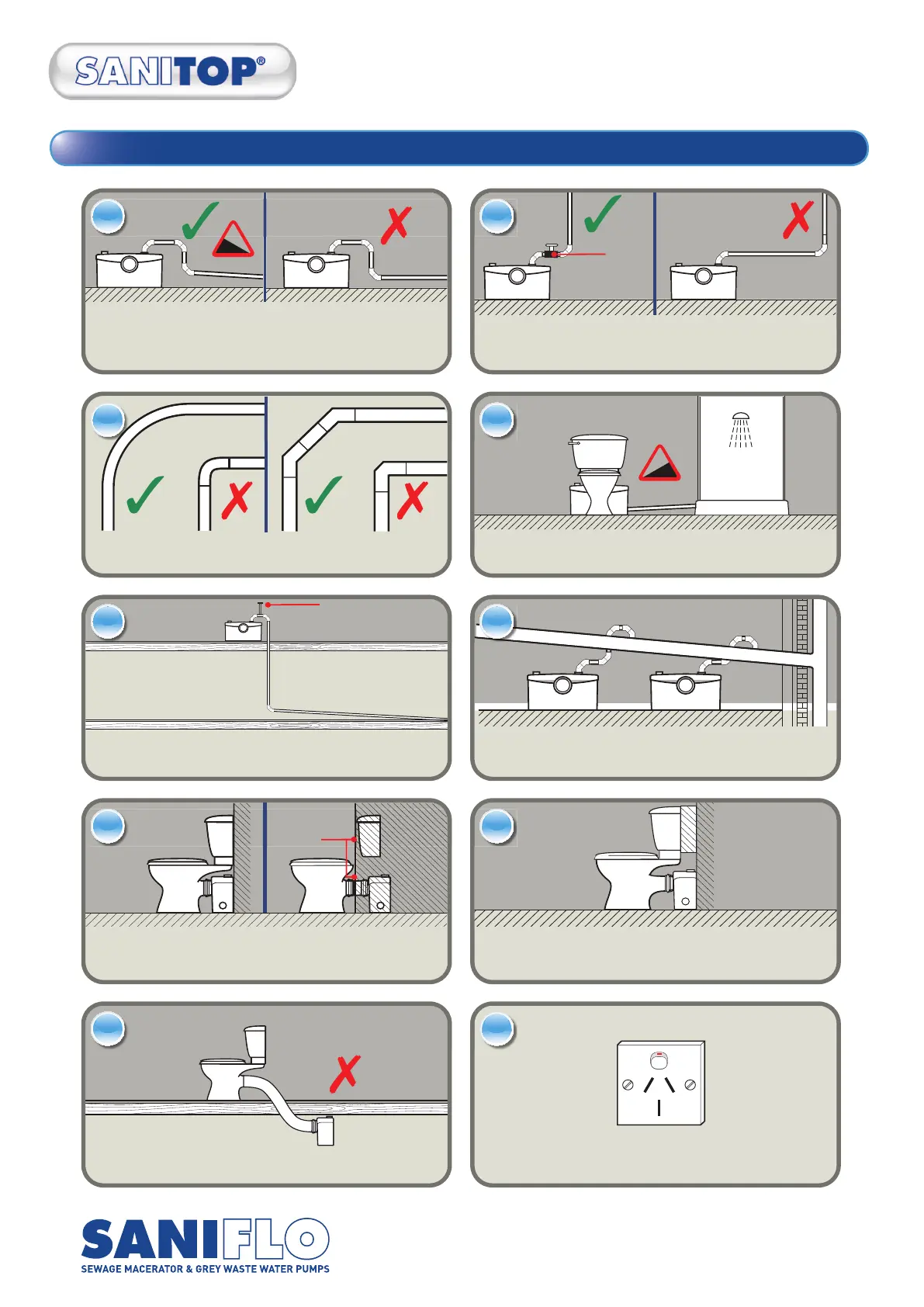

SANITOP PAGE 9

1 2

3 4

5 6

7 8

9 10

All horizontal pipes should have a minimum fall of 1:100.

Discharge pipework should be solvent UPVC.

Do not “pushfit” pipework/fittings.

If a vertical rise is needed, this should be at the start of the run

(within 30cm of the unit).

Bends should be smooth/long radius, not tight elbows.

Examples of uPVC Pressure Pipe and fittings shown.

Waste Pipes entering the Saniflo unit should have a

gravity fall of 1:40

2 x 45˚ Offset

Plastic Elbows

Where the pipework falls below floor level, fit an air admittance

valve at the highest point capable of withstanding 10psi neg

pressure, or upsize pipe coming down to break syphonage.

Each Saniflo discharge pipe should run separately to the sewer/vent

pipe. If wastes are combined, it can only be connected to a larger pipe.

This pipe must gravity fall to connection point.

The unit should be easily accessible and removable in the event of service

or maintenance being required. If boxed in, the boxing should be easily

removed. Any extension between the WC pan spigot and wall should not

exceed 150mm and have a 1.40 fall.

As close coupled cistern dimensions vary it may be

necessary with certain designs to utilise a spacer between

cistern and wall.

Position the Saniflo unit directly behind the toilet pan,

not underneath it.

Connect to power according AS/NZS 3000: 2007 Electrical Regulation

as rules apply depending on location. In ALL CASES

supply must be protected by a 30mA RCD rated at 16A.

Easily

removable

panels

Air admittance

valve

1:100

PVC

Ball Value

ELECTRICAL CLASS 1 PRODUCT

After sales contact information: info@saniflo.com.au

15. Ten golden rules for correct installation

Loading...

Loading...