24

6. LUBRICATION

6-1 Headstock Lubrication

Headstock lubrication is splash injection type. Oil grooves are equipped around the

headstock to provide lubricant flowing from oil grooves to spindle, then finally reach

the bottom of the headstock. To add oil, take off the oil plug on the top of the

headstock cover, fill to the centerline of oil sight glass. Oil drain hole is located on the

right bottom side of the headstock.

Before operating the lathe, be sure the headstock is filled with oil. If not, add Shell

Tellus ○

32

. Exchange oil after one month use for the first time. Thereafter every two

months.

6-2 Gear Box & Apron Lubrication

1. Gear box is a reservoir oil bath type. To ensure the long service life of gear box

and bedways, exchange the oil of gear box every six months.

2. Apron is also a reservoir oil bath type. Add the oil as soon as the oil is lower than

the center line of the sight glass.

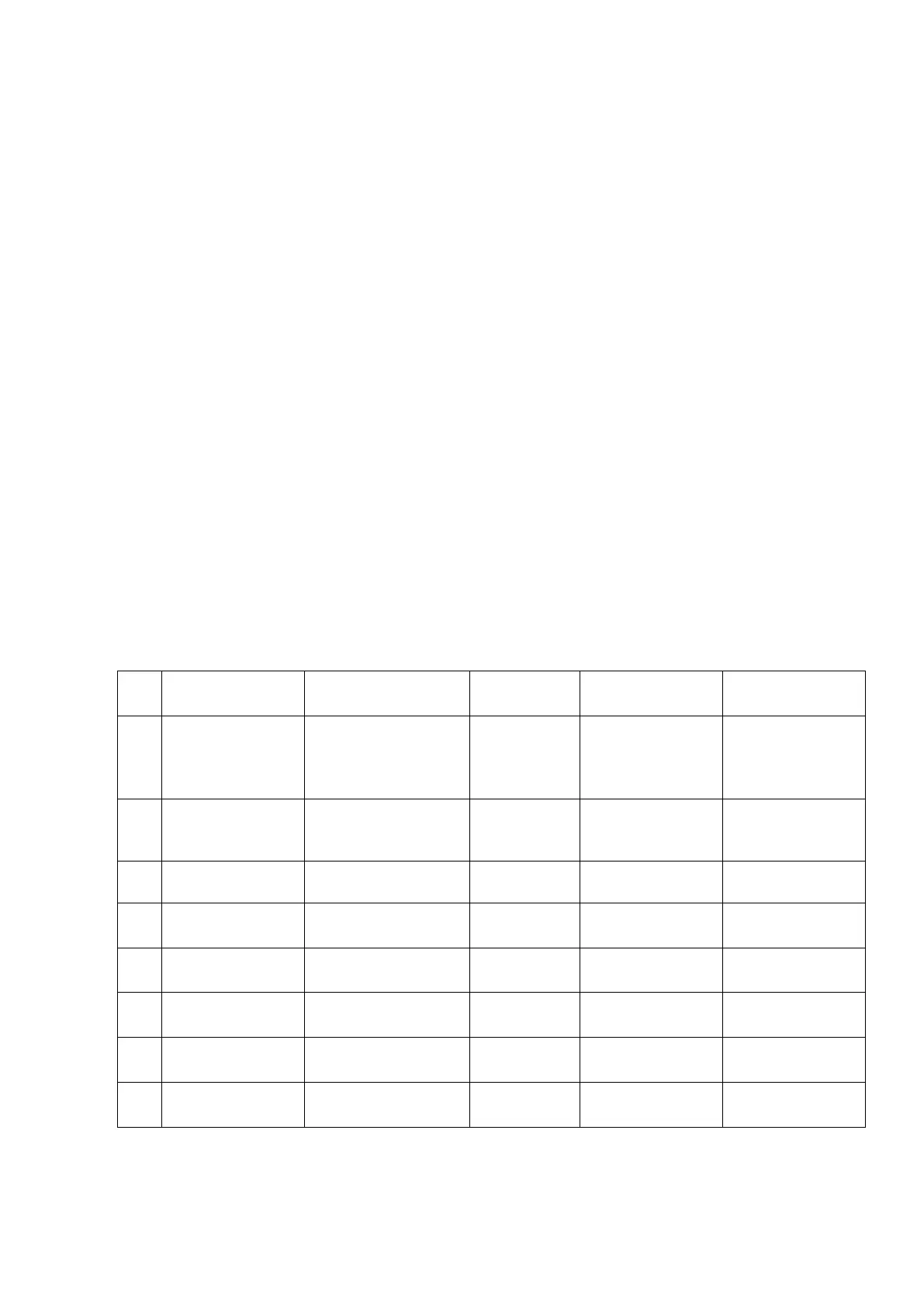

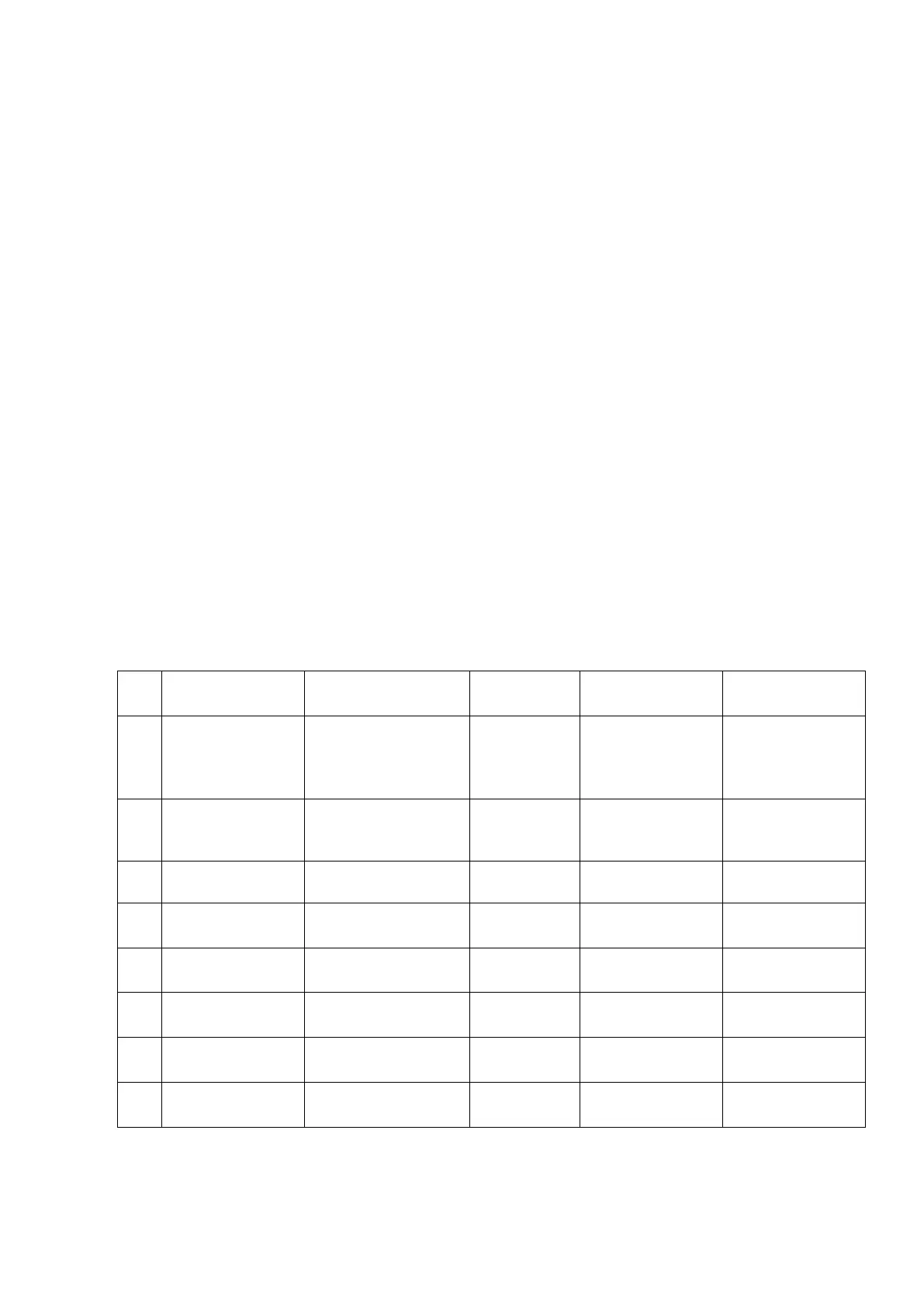

6-3 Lubrication Charts

Loosen the oil input

hole screw on the

left top side of the

headstock cover

One month at the

beginning,

thereafter once

two months.

Open the top cover

and loosen the oil

input hole screw

Loosen the oil input

hole screw

Press the manual oil

pump

Loading...

Loading...