LC-42D43U

3 – 1

LC-42D43U

Service Manual

CHAPTER 3. ADJUSTMENT

[1] ADJUSTMENT PROCEDURE

The adjustment values are set to the optimum conditions at the factory before shipping. If a value should become improper or an adjustment is

required due to part replacement, make an adjustment according to the following procedure.

1. After replacement of any PWB unit and/or IC for repair, please note the following.

When replacing the following units, make sure to prepare the new units loaded with updated software.

MAIN Unit: DUNTKD862FM04.

AV TERMINAL Unit: DUNTKD935FM03

2. Signal Adjustment

2.1. White balance adjustment

Adjustment item Adjustment conditions Adjustment procedure

1 Setting For detailed adjustment procedure, refer to “Kameyama Model Integral Monitor WB

Adjustment Specifications V1.4”.

1) Make the following settings for the set.

AV MODE: [DYNAMIC]

Backlight: +16

Aging time: Min. 60 minutes

2) Connect the white balance adjustment tool to the set.

2 Automatic adjust-

ment execution

[Command]

Process mode

KRSW0001

KKT10037

Setting

KYOF0000

OSDS0001

SBSL0016

Multi-point adjustment

mode

MSET0001

Adjustment value initializa-

tion

MSET0004

Point 6

LEV60232

(WBI60928)

MG6G****

MG6B****

MG6R****

Point 5

LEV50200

(WBI50800)

MG5G****

MG5B****

MG5R****

[Adjustment procedure]

1) Using the remote controller, transmit the “monitor adjustment process” code.

2) Set the 6th point to the specified gradation level. With the strongest color being fixed,

turn down the R, G and B settings to their reference levels.

3) Set the 5th point to the specified gradation level. Correct the G setting (860 x 6th-

point G setting / 920) (rounded off), and make the R and B settings to their reference

levels.

4) Set the 4th point to the specified gradation level. Correct the G setting (736 x 6th-

point G setting / 920) (rounded off), and make the R and B settings to their reference

levels.

5) Set the 3rd point to the specified gradation level. Correct the G setting (512 x 6th-

point G setting / 920) (rounded off), and make the R and B settings to their reference

levels.

6) Set the 2nd point to the specified gradation level. Correct the G setting (256 x 6th-

point G setting / 920) (rounded off), and make the R and B settings to their reference

levels.

7) Set the 1st point to the specified gradation level. Correct the G setting (192 x 6th-

point G setting / 920) (rounded off), and make the R and B settings to their reference

levels.

8) With the MSET0003 command, write the adjustment values and turn off the AC

power.

* Initial R, G and B settings at point 6: Gradation level set at 920

* Initial R, G and B settings at points 1 thru 5: Corrected G setting at each point

(This is because the adjustment is made to achieve the same remainder of RGB setting /

4 at each point.)

[Adjustment value]

•As per the “standard set” submitted by Engineering Department

“LC-42HT3U” Teaching set

[Adjustment reference] Instrument: Minolta CA-210 Engineering instrument

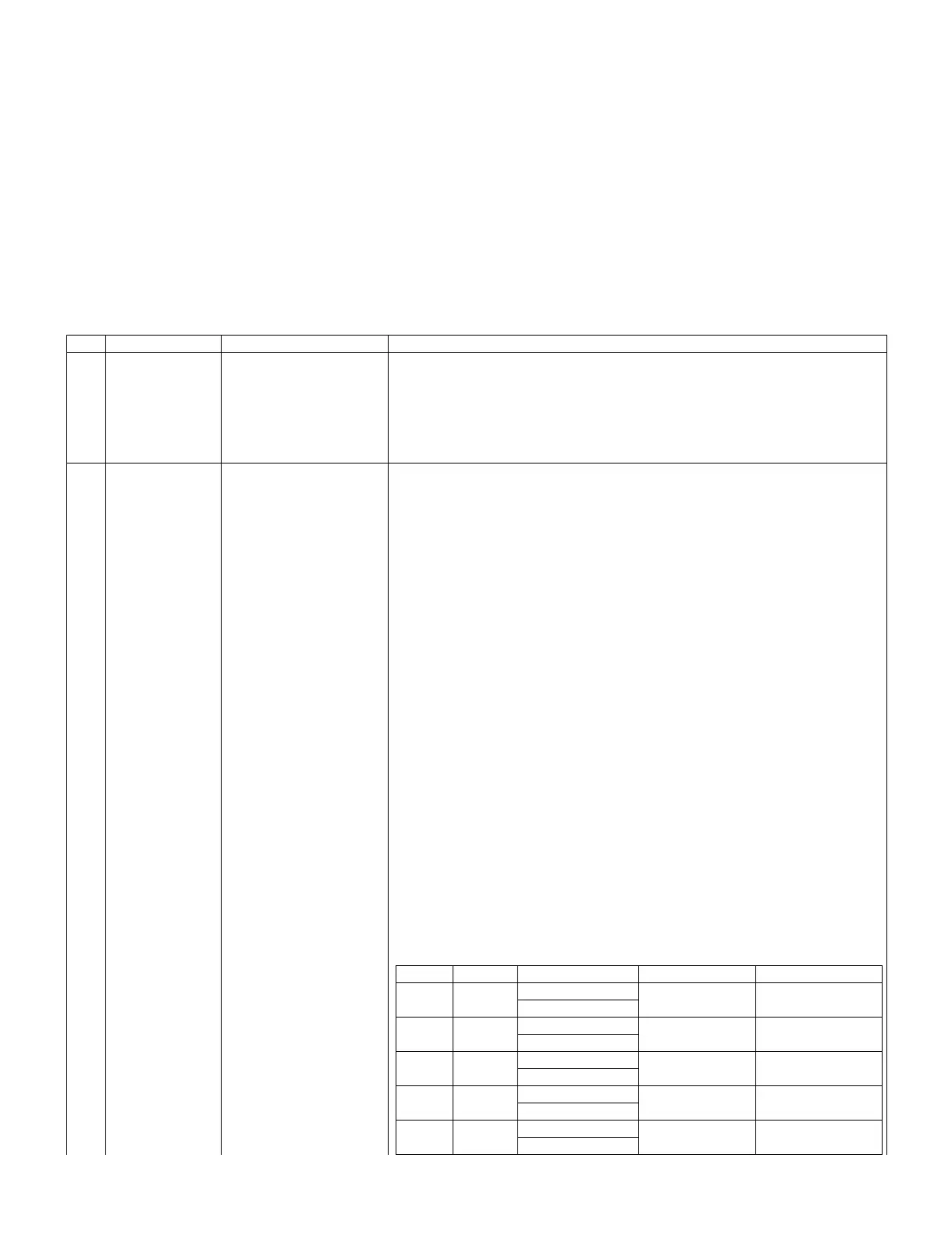

Point 4 Level Reference Adj. spec Ins. spec

LEV40164 Point 6 928 X=0.272 ±0.0025 ±0.0050

(WBI40656) y=0.277

MG4G**** Point 5 800 X=0.272 ±0.0025 ±0.0050

MG4B**** y=0.277

MG4R**** Point 4 656 X=0.272 ±0.0035 ±0.0070

y=0.277

Point 3 Point 3 528 X=0.272 ±0.0050 ±0.0100

LEV30132 y=0.277

(WBI30528) Point 2 352 X=0.272 ±0.0080 ±0.0150

MG3G**** y=0.277

Loading...

Loading...