MX-C250 SIMULATION 6 – 31

44

44-1

Purpose

Setting

Function (Purpose)

Used to set each correction operation func-

tion in the image forming (process) section.

Section

Image process (Photoconductor/Develop-

ing/Transfer/Cleaning)

Operation/Procedure

1) Select an item to be set with Arrow keys.

2) Enter the set value with 10 keys.

3) Press [OK]/[START] key.

The set value in step 2) is saved.

NOTE:

Set the items to the default values unless a change is spe-

cially required.

44-2

Purpose

Adjustment/Setup

Function (Purpose)

To execute the light quantity adjustment for

process control sensor and registrations

sensors (2pcs are done at same time), and

reading the surface of belt.

Section

Process

Operation/Procedure

When [OK]/[START] key is pressed, the adjustment is executed

automatically.

After completion of the adjustment, the adjustment result is dis-

played.

If the adjustment is not executed normally, "ERROR" is displayed.

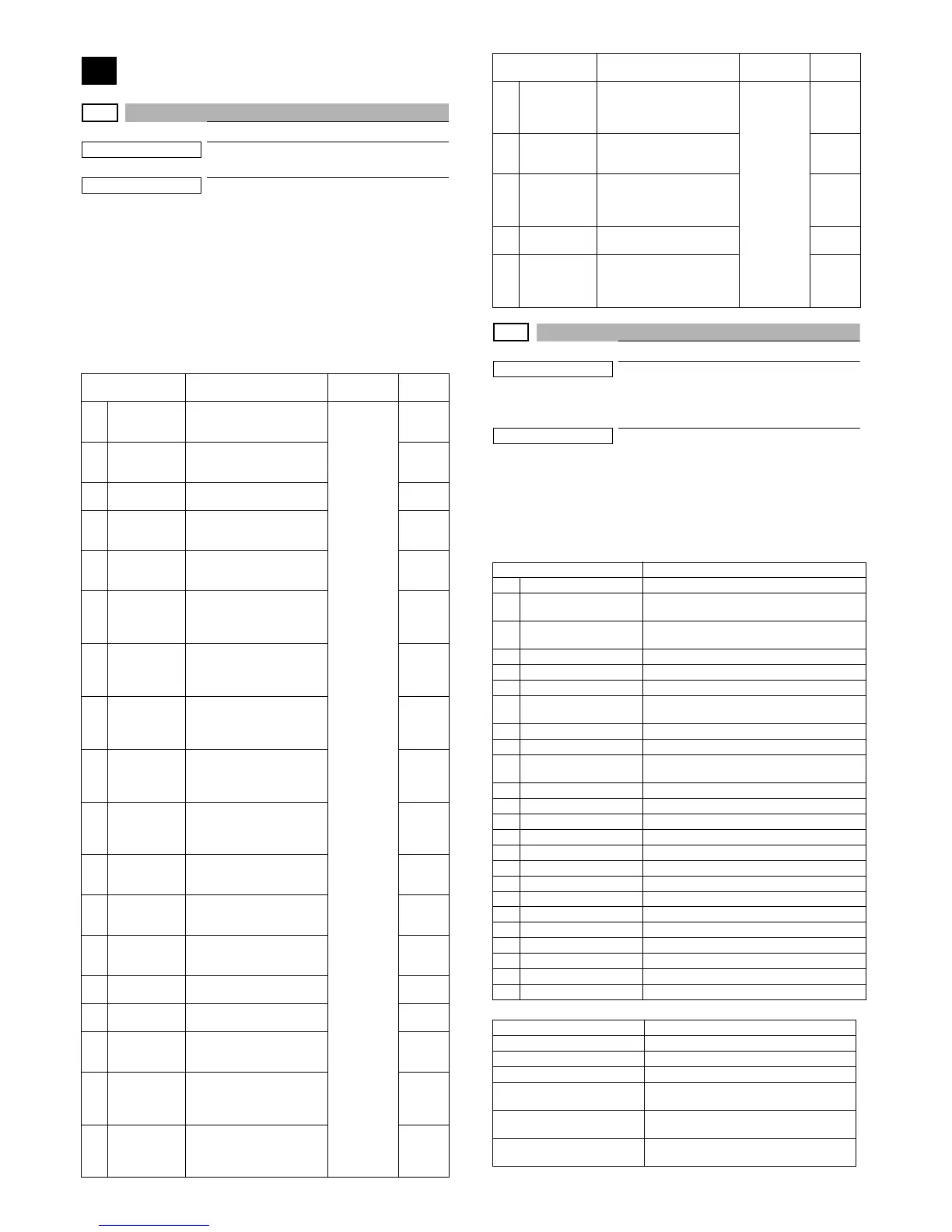

Item/Display Content

Setting

range

Default

value

1HV

Normal operation high

density process control

Enable/Disable setting

Normal

(Disable : 1

: NO)

Reverse

(Enable : 0 :

YES)

0

2HT

Normal operation half tone

process control Enable/

Disable setting

0

3TC

Transfer output correction

Enable/Disable setting

0

4MD VG

Membrane decrease grid

voltage correction Enable/

Disable setting

0

5MD LD

Membrane laser power

voltage correction Enable/

Disable setting

0

6MD EV

Membrane decrease envi-

ronment grid voltage cor-

rection Enable/Disable

setting

0

7 MD DL

Membrane decrease dis-

charge light quantity cor-

rection

Enable/Disable setting

0

8 MD DL EV

Membrane decrease envi-

ronment discharge light

quantity correction

Enable/Disable setting

0

9MD LD EV

Membrane decrease envi-

ronment discharge light

quantity correction Enable

/ Disable setting

1

10 LD PROCON

Membrane laser power

voltage correction by pro-

cess control Enable / Dis-

able setting

0

11 TN PIX SUP

Toner supply control by

yield count Enable / Dis-

able setting

0

12 TN FB

FEEDBACK toner density

correction enable / disen-

able setting

0

13 TN INT

Interval toner supply con-

trol enable / disenable set-

ting

0

14 TN RECV

Developer recovery enable

/ disenable setting

0

15 TN ADJ

Sensor output adjustment

enable / disenable setting

0

16 TN EMP

Control the detection of

toner drop amount enable/

disenable setting

0

17 TN EMP INT

Control the detection of

toner drop amount when

job intermission enable /

disenable setting

0

18

TN EMP

NEW

Control the detection of

toner drop amount when

installed new cartridge

enable / disenable setting

0

19 TN PIX TBL

Execution the calculation

of yield count correction

table enable / disenable

setting

Normal

(Disable : 1

: NO)

Reverse

(Enable : 0 :

YES)

0

20 AR AUTO

Auto registration adjust-

ment Enable / Disable set-

ting

0

21 AR ERROR

Auto registration adjust-

ment execution error

check Enable / Disable

setting

0

22 DM PHASE

Drum phase fitting Enable/

Disable setting

0

23 PRT_HT

Half tone process control

printer correction feed-

back Enable/Disable set-

ting

0

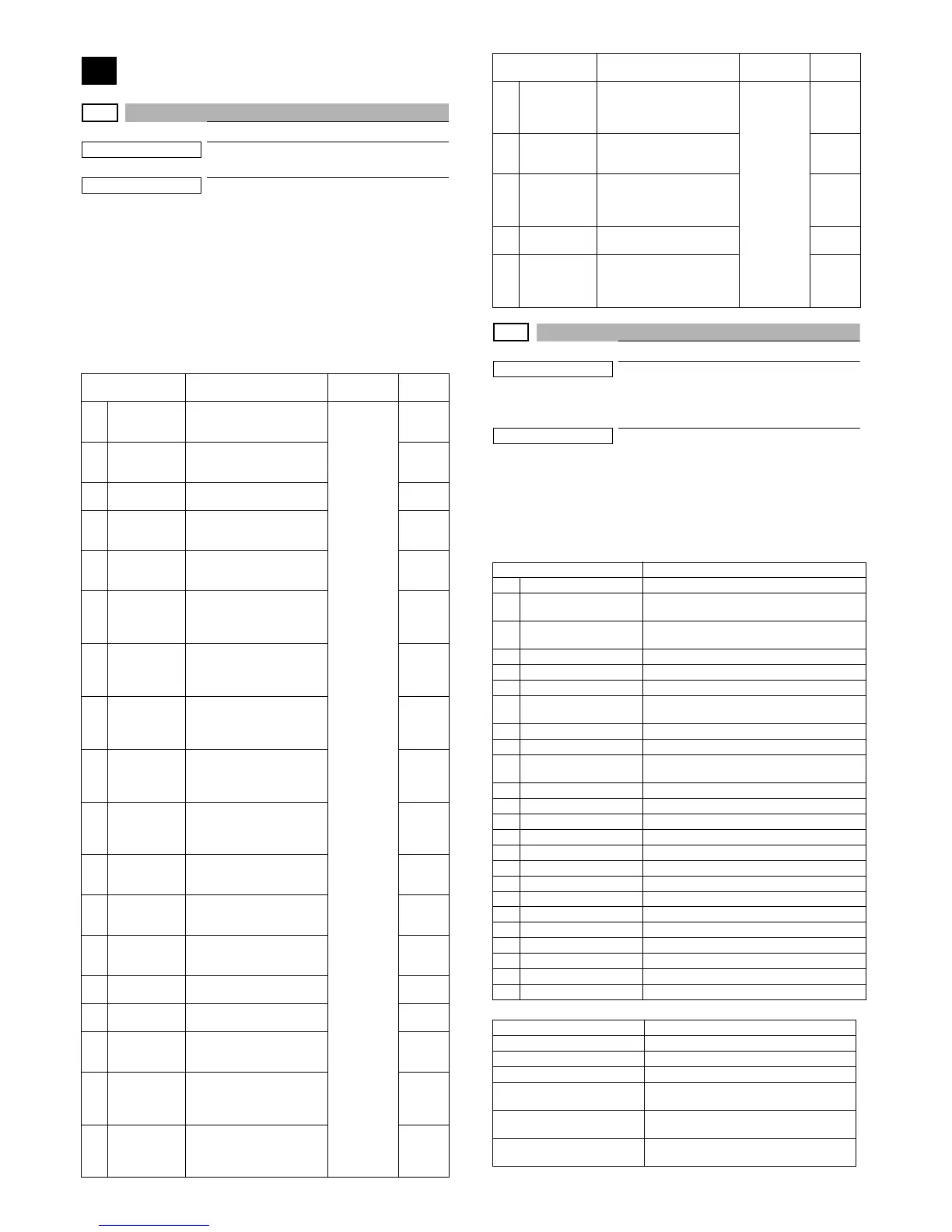

Item/Display Content

1 P_F_CL_ka F side color sensor correction factor

2 P_F LED ADJ F sensor light emitting quantity adjustment

value

3 P_R LED ADJ R sensor light emitting quantity adjustment

value

4 P_F_CL_DARK Dark voltage of color (F side)

5 P_F DARK Dark voltage of sensor (F side)

6 P_R DARK Dark voltage of sensor (R side)

7 P_F GRND Belt substrate when the item D adjust-ment

is completed.

8 P_F BELT MAX Belt substrate input max. value

9 P_F BELT MIN Belt substrate input min. value

10 P_R GRND Belt substrate when the item F adjust-ment

is completed.

11 P_R BELT MAX Belt substrate input max. value

12 P_R BELT MIN Belt substrate input min. value

13 REG_F BELT MAX Belt substrate input max. value (F side)

14 REG_F BELT MIN Belt substrate input min. value (F side)

15 REG_R BELT MAX Belt substrate input max. value (R side)

16 REG_R BELT MIN Belt substrate input min. value (R side)

17 REG_F PATCH(K) Patch light receiving potential F(K)

18 REG_F PATCH(C) Patch light receiving potential F(C)

19 REG_F PATCH(M) Patch light receiving potential F(M)

20 REG_F PATCH(Y) Patch light receiving potential F(Y)

21 REG_R PATCH(K) Patch light receiving potential R(K)

22 REG_R PATCH(C) Patch light receiving potential R(C)

23 REG_R PATCH(M) Patch light receiving potential R(M)

24 REG_R PATCH(Y) Patch light receiving potential R(Y)

Error name Error content

CL_SEN_ADJ_ERR Color sensor adjustment abnormality

BK_SEN_ADJ_ERR Black sensor adjustment abnormality

P_F_CL_ka F Color sensor adjustment abnormality

P_F_GRND F sensor basis material reading abnor-

mality

P_R_GRND F sensor basis material reading abnor-

mality

REG_F_LED_ADJ Registration sensor F adjustment abnor-

mality

Item/Display Content

Setting

range

Default

value

Loading...

Loading...