MECHANICAL ADJUSTMENT

TORQUE

CHECK

AT PLAY,

FAST

FORWARD AND

REWIND

MODES

(See

Table

3.)

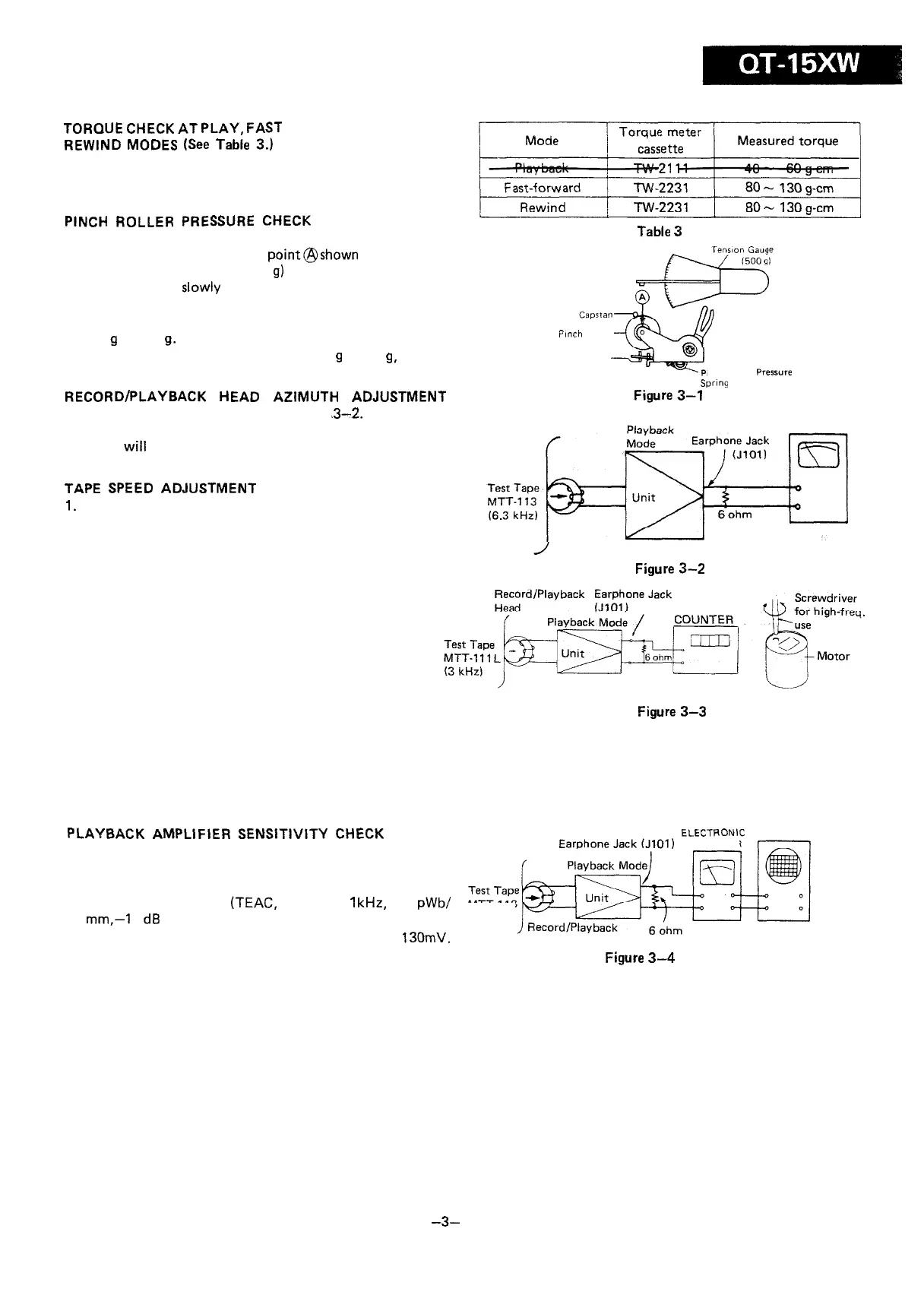

Put a

torque

meter cassette in the cassette holder of the unit,

and see that the measured torque in each mode is normal as

shown in Table 3.

PINCH

ROLLER

PRESSURE

CHECK

1. Place the unit in playback mode.

Table

3

2. Push the pinch roller, at the

point@shown

in Figure 3-1,

by using a tension gauge (500

g)

so that it will come off the

capstan. Then,

slowly

release the tension until the pinch

roller hits the capstan again (i.e., the pinch roller is about to

rotate again). Check, then, the tension gauge is reading

300

g

to 400

g.

Pfnch

Roller

3. If the reading is outside the range of 300

g

to 400

g,

replace

the pressure spring of the pinch roller.

inch Roller

Pressure

swng

RECORD/PLAYBACK HEAD AZIMUTH ADJUSTMENT

1. Connect instruments as shown in Figure

.3-2.

2. Adjust the head azimuth adjusting screw so that the output

signal

will

have maximum waveform.

Figure

3-l

ELECTRONIC

VOLTMETER

TAPE

SPEED

ADJUSTMENT

1.

Connect instruments as shown in Figure 3-3.

2. Put a screwdriver (for high-frequency use) into the hole of

the motor, and adjust the variable resistor so that the

output frequency is 2955 Hz to 2980 Hz on frequency

counter.

Record/Playback

Head

Figure

3-2

FREQUENCY

Figure

3-3

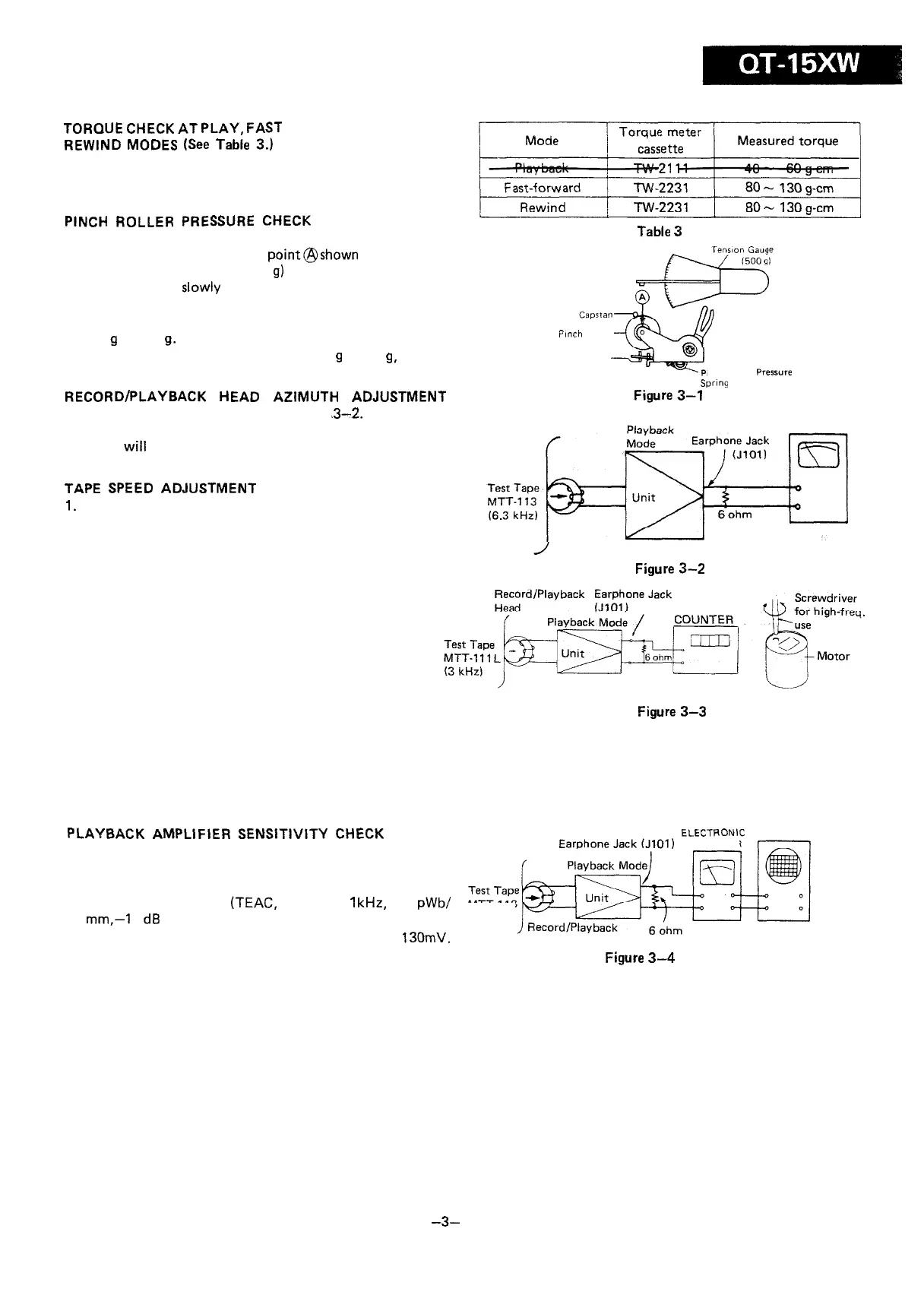

ELECTRICAL ADJUSTMENT

PLAYBACK AMPLIFIER

SENSITIVITY

CHECK

1. Connect instruments as shown in Figure 3-4.

2. Set the mode selector switch at tape, the volume control

knob at max.

ELECTRONIC

OSCILLOSCOPE

01)

VOLTMETER

3. Playback a test tape

(TEAC,

MTT-118,

1

kHz,

250

pWb/

MTT-118

mm,-1

0

d8

prerecorded).

4. See that the electronic voltmeter is reading about

130mV.

Head

Figure

3-4

-3-

Loading...

Loading...