R969(W)

9 – 1

R969(W)

Service Manual

CHAPTER 9. TOUCH CONTROL PANEL ASSEMBLY

[1] OUTLINE OF TOUCH CONTROL PANEL

The touch control section consists of the following units as shown in

the touch control panel circuit.

(1) Key Unit

(2) Control Unit (The Control unit consists of Power unit and CPU unit.)

The principal functions of these units and signals communicated

among them are explained below.

1. Key Unit

The key unit is composed of a matrix, signals generated in the LSI are

sent to the key unit from P10, P11, P12, P13, P14, P15, P16 and P17.

When a key pad is touched, a signal is completed through the key unit

and passed back to the LSI through P70, P71, P72 and P73 to perform

the function that was requested.

2. Control Unit

Control unit consists of LSI, power source circuit, synchronizing signal

circuit, ACL circuit, buzzer circuit, relay circuit, temperature measure-

ment circuit, indicator circuit, absolute humidity sensor circuit and back

light circuit.

1) LSI

This LSI controls the temperature measurement signal, absolute

humidity sensor signal, key strobe signal, relay driving signal for

oven function and indicator signal.

2) Power Source Circuit

This circuit generates voltage necessary in the control unit.

3) Synchronizing Signal Circuit

The power source synchronizing signal is available in order to com-

pose a basic standard time in the clock circuit. It accompanies a

very small error because it works on commercial frequency.

4) ACL

A circuit to generate a signal which resets the LSI to the initial state

when power is supplied.

5) Buzzer Circuit

The buzzer is responsive to signals from the LSI to emit audible

sounds (key touch sound and completion sound).

6) Door Sensing Switch (Stop Switch)

A switch to “tell” the LSI if the door is open or closed.

7) Relay Circuit

To drive the magnetron, grill heating element, convection heating

element, convection motor, fan motor, turntable motor, damper

motor, touch control transformer and light the oven lamp.

8) Back Light Circuit

A circuit to drive the back light (Light emitting diodes LD10 - LD19).

9) Indicator Circuit

This circuit consists 40-segments and 16-common electrodes using

a Liquid Crystal Display.

The Liquid Crystal Display (LCD) is drive by LCD driver IC3.

10)Temperature Measurement Circuit: (OVEN THERMISTOR)

The temperature in the oven cavity is sensed by the thermistor. The

variation of resistance according to sensed temperature is detected

by the temperature measurement circuit and the result applied to

LSI. The LSI uses this information to control the relay and display

units.

11)Damper Switch

A switch to tell the LSI if the damper is open or close.

12)Absolute Humidity Sensor Circuit

This circuit detects the humidity of the food which is being cooked,

to control its automatic cooking.

[2] ABSOLUTE HUMIDITY SENSOR CIRCUIT

1. Structure of Absolute Humidity Sensor

The absolute humidity sensor includes two thermistors as shown in the

illustration. One thermistor is housed in the closed vessel filled with dry

air while another in the open vessel. Each sensor is provided with the

protective cover made of metal mesh to be protected from the external

airflow.

2. Operational Principle of Absolute Humidity Sen-

sor

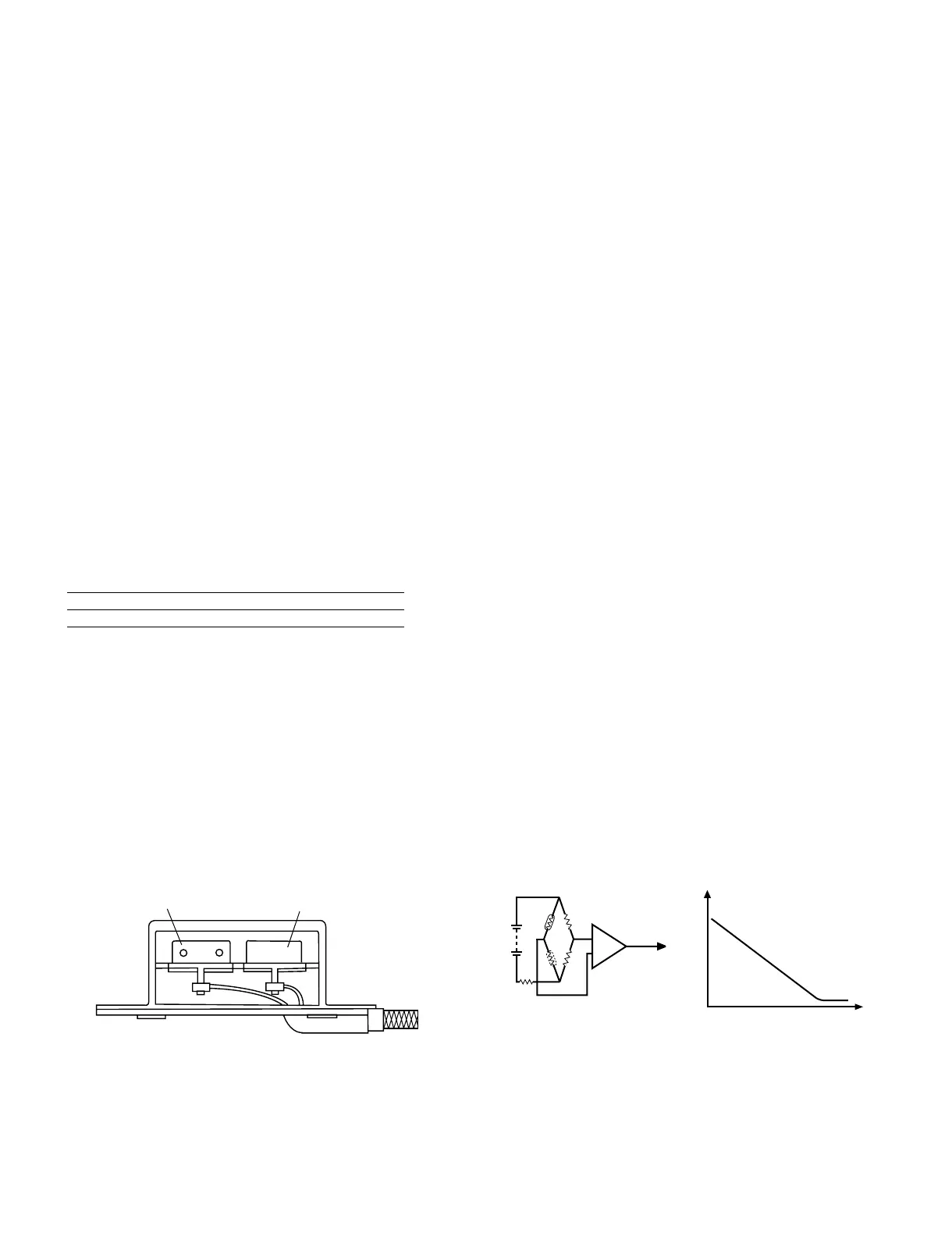

The figure below shows the basic structure of an absolute humidity

sensor. A bridge circuit is formed by two thermistors and two resistors

(R1 and R2). The output of the bridge circuit is to be amplified by the

operational amplifier.

Each thermistor is supplied with a current to keep it heated at about

150°C, the resultant heat is dissipated in the air and if the two ther-

mistors are placed in different humidity conditions they show different

degrees of heat conductivity leading to a potential difference between

them causing an output voltage from the bridge circuit, the intensity of

which is increased as the absolute humidity of the air increases. Since

the output is very minute, it is amplified by the operational amplifier.

Symbol Voltage Application

VC -5.2V LSI(IC1)

Sensing part

(Open vessel)

Sensing part

(Closed vessel)

C

S

R3

R1

R2

+

-

Operational

amplifier

Output

voltage

S : Thermistor

open vessel

C : Thermistor

closed vessel

2

Absolute humidity (g/m )

O

u

t

p

u

t voltage

Absolute humidity vs,

output voltage characteristic

Loading...

Loading...