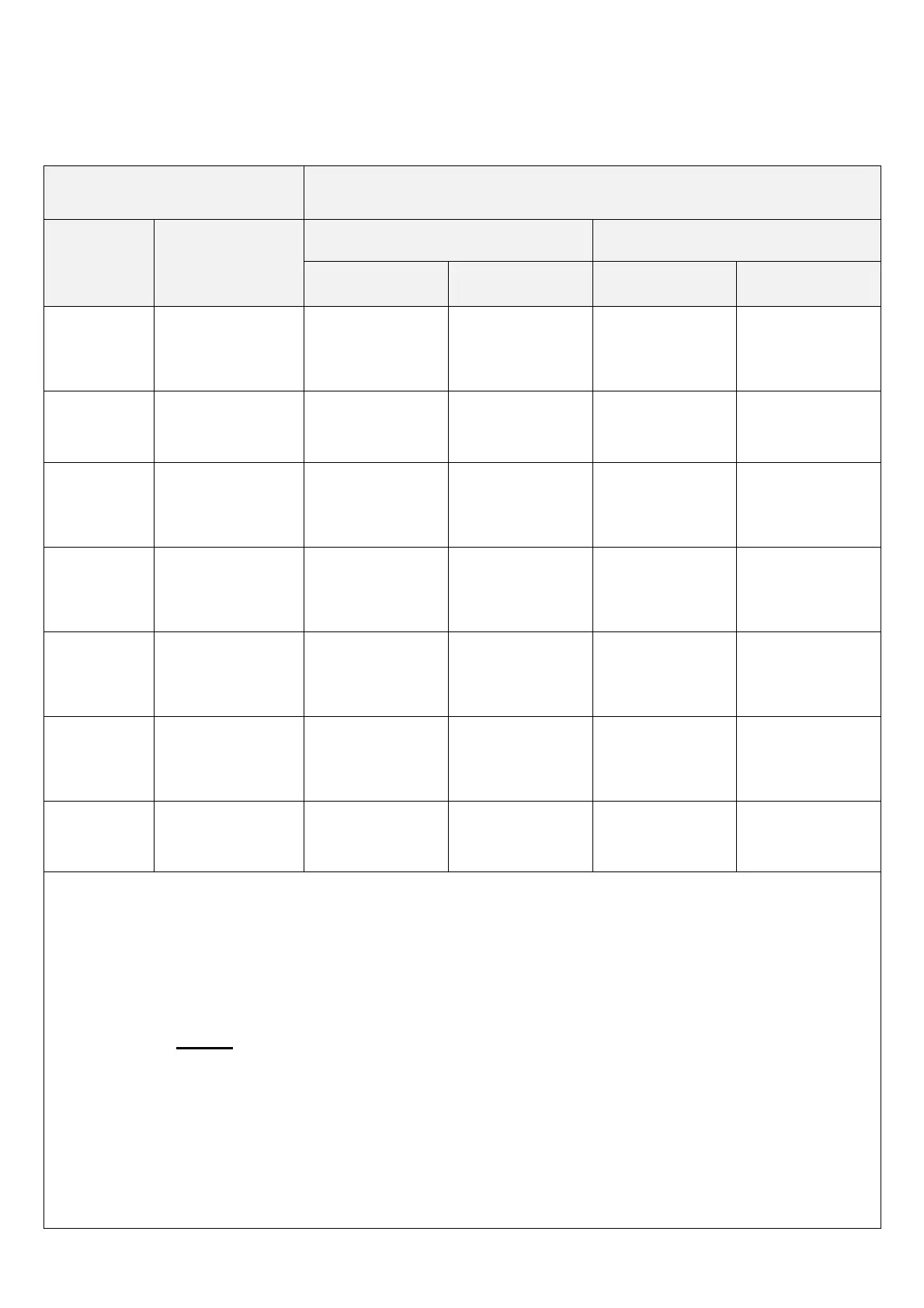

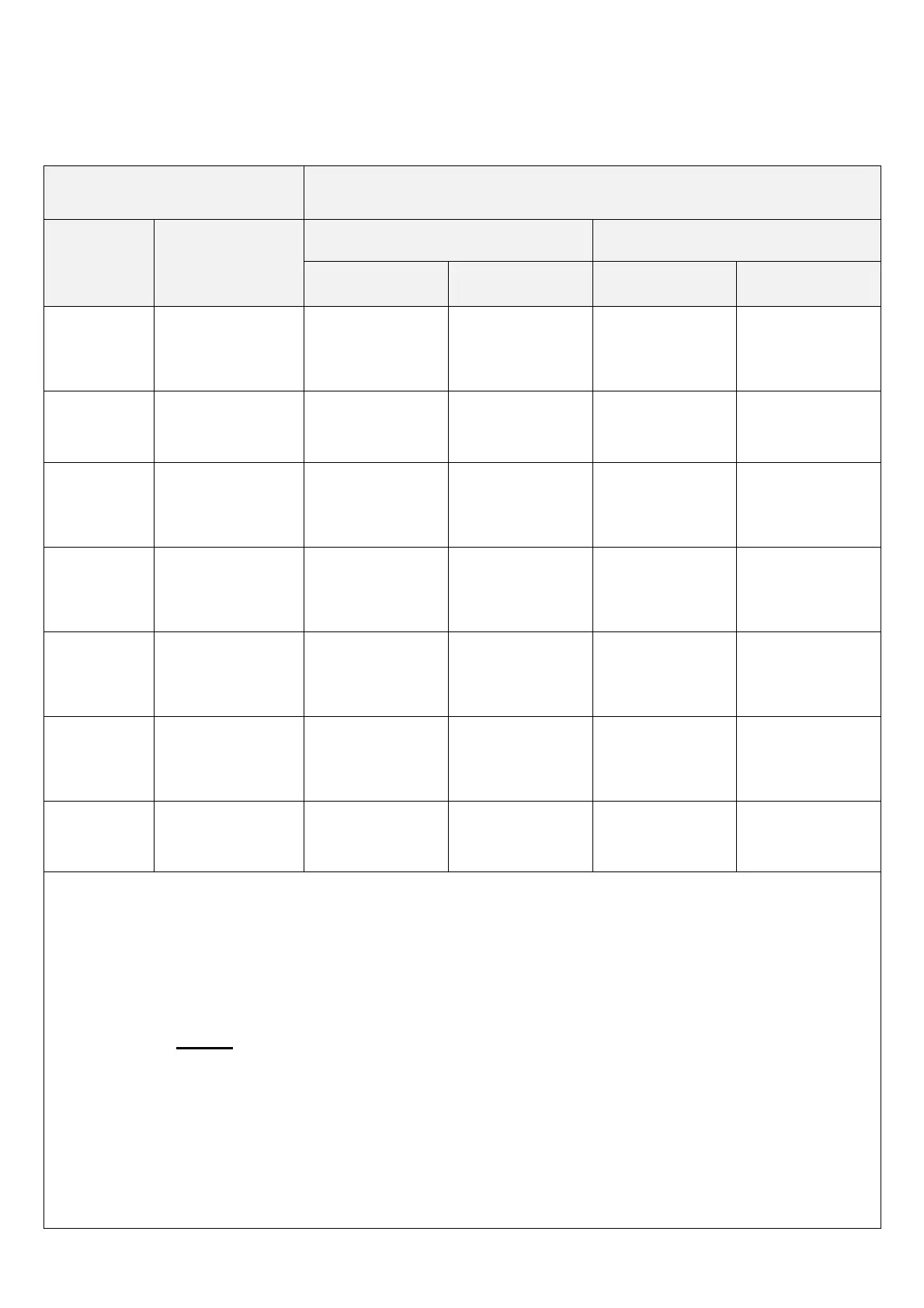

6. Suggested starting speed and feeds

6-1 Carbide cutters

Table – 5

Working Piece Cutting Speed

Material

Brinell Hardness

HB

High – Speed Steel Cutter Super – Hard Alloy Cutter

M/Min FT/Min M/Min FT/Min

Special steel

Hard

Tough

Annealed

300-400

220-300

180-220

38-45

45-70

70-110

30-50

50-75

75-108

90-150

150-225

225-325

Low carbon

steel

Malleable

Cut well

152-197

150-180

85-140

110-140

90-130

108-130

270-400

325-400

Cast iron

Hard

Medium hard

Soft

220-300

180-220

150-180

45-70

70-100

110-140

50-70

75-108

108-130

150-225

225-325

325-400

Brass and

bronze

Hard

Medium hard

Soft

21-46

46-83

83-116

65-140

140-250

250-350

63-130

130-200

200-330

190-400

400-600

600-1000

Magnesium

and its

alloys

Aluminum

and its

alloys

Plastic

Note: The above table should be regarded as a general criterion.

Attention must be paid to the following when operating the machine.

Loading...

Loading...