2-5 Cutting oil

There are two general types of cutting oil, i.e., water-soluble cutting oil and

water-insoluble cutting oil, and these are further divided into many groups. As selection of

the cutting oil depends on each cutting condition, particular trade names or groups cannot be

specified here but it is necessary to observe the following:

(1) Use of water-insoluble cutting oil.

Examples:

Mineral oil Light oil, machine oil and spindle oil

Animal and vegetable oil

Lard, olive oil, colza oil, soybean oil and

castor oil

(2) The capacity of the cutting oil tank is approximately 9.25 gallons.

(3) Cutting oil should be supplied through an oil strainer into the cutting oil intake

provided on the lower part of the column.

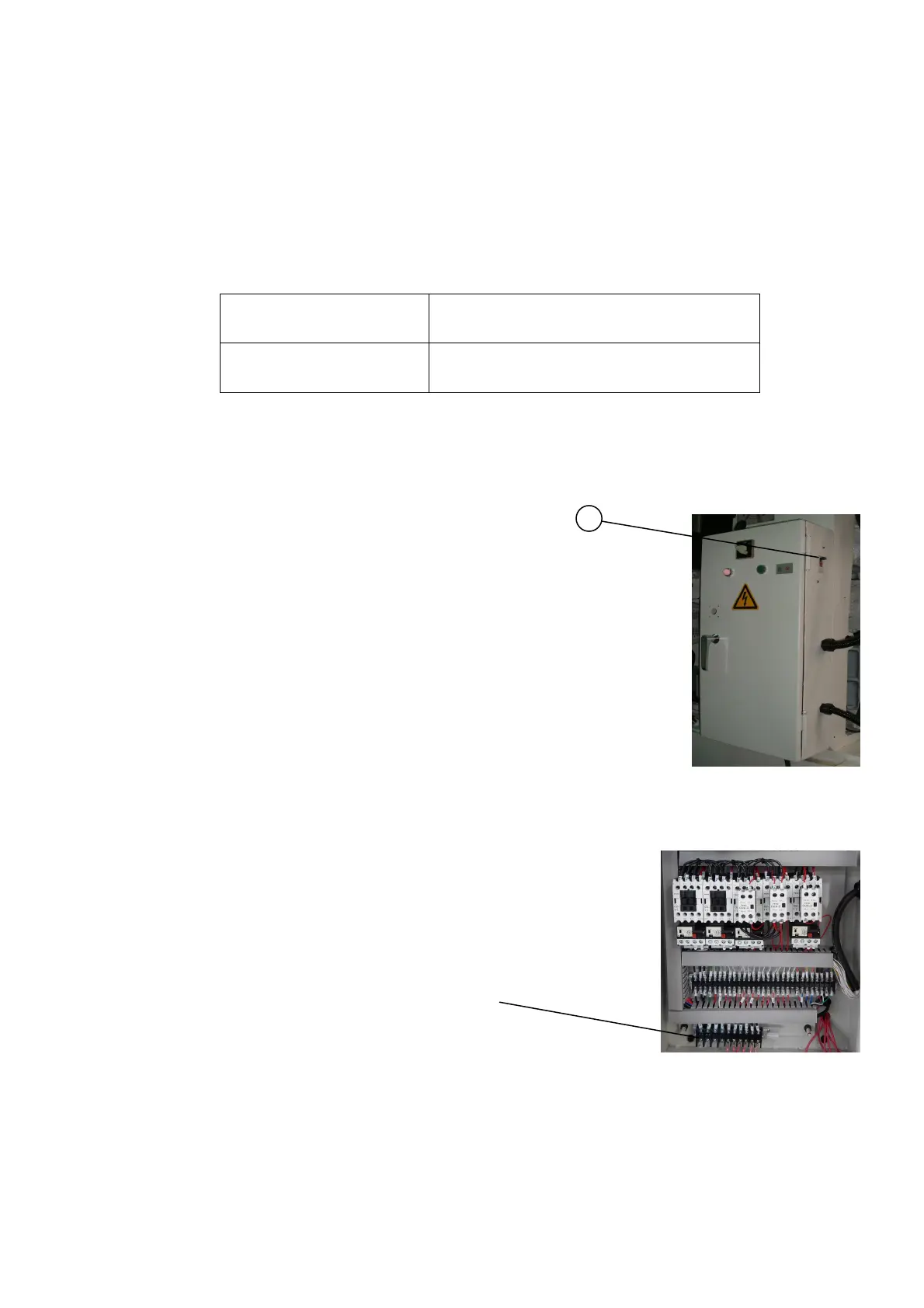

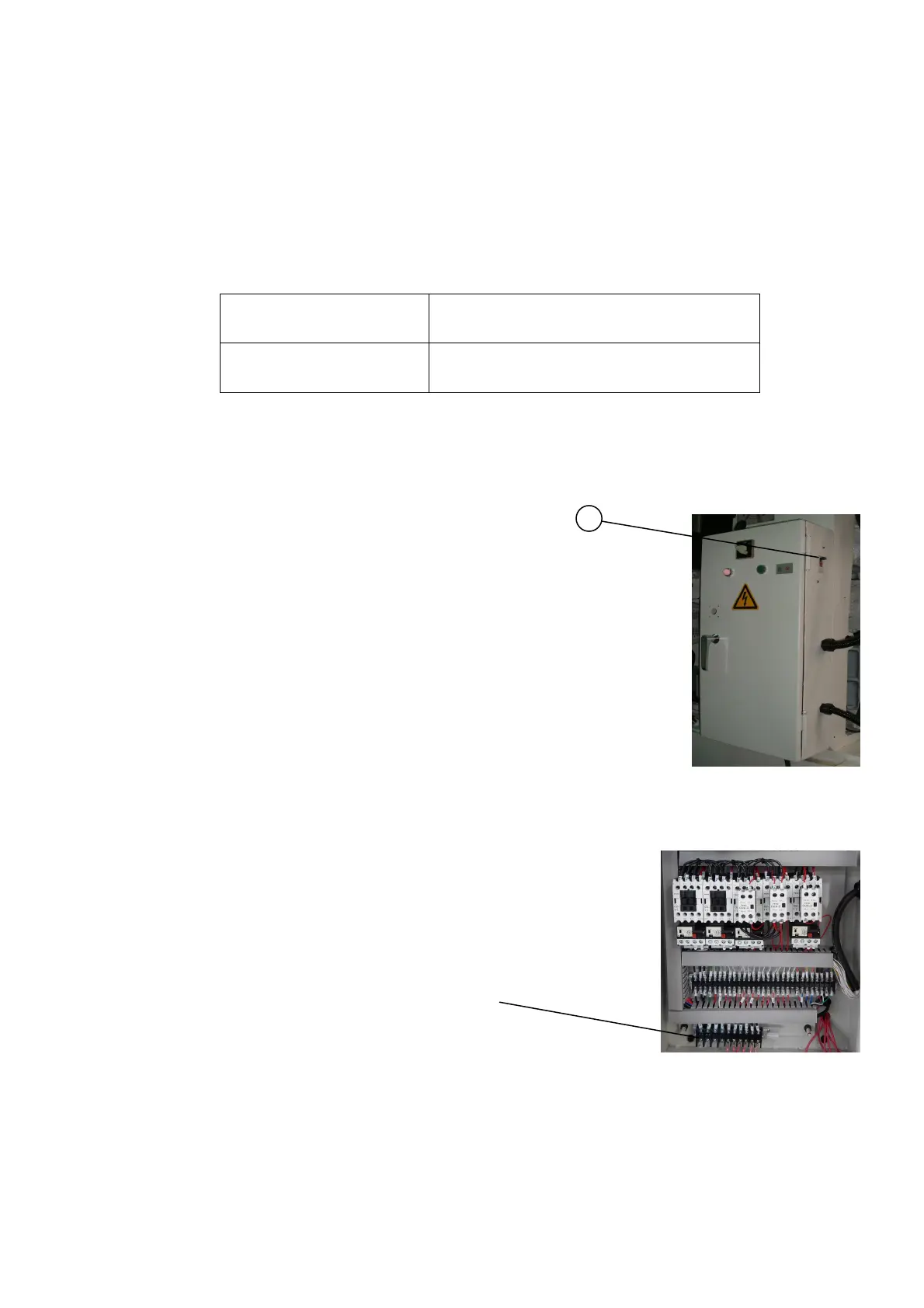

2-6 Wiring

The power cord should be connected to the

terminals R.S.T. (Fig. 4-2). On completion of

the connection, turn on the power switch (Fig. 4-1)

provided on the side of the power box and turn the spindle

rotating direction indicating change over switch to the right.

After finishing the above preparations, start the main spindle.

(See section for spindle starting, spindle stopping and spindle

brake).If the rotation direction of the main spindle is

clockwise, connections are correct. If rotation is counter-

clockwise, exchange connections of two of the three wires

of the power core.

2-7 Lubrication

Prior to starting, each moving part must be lubricated with suitable lubricating oil. Refer

to (Table.1) for instructions to lubricate the spindle head gears, quill and slide ways.

The Lubrication oil to be used for each part is also listed in Table 2 and 3. It can be used

for selecting the correct lubricant to keep the machine in its best condition.

Fig. 4-1

Fig. 4-2

②

Loading...

Loading...