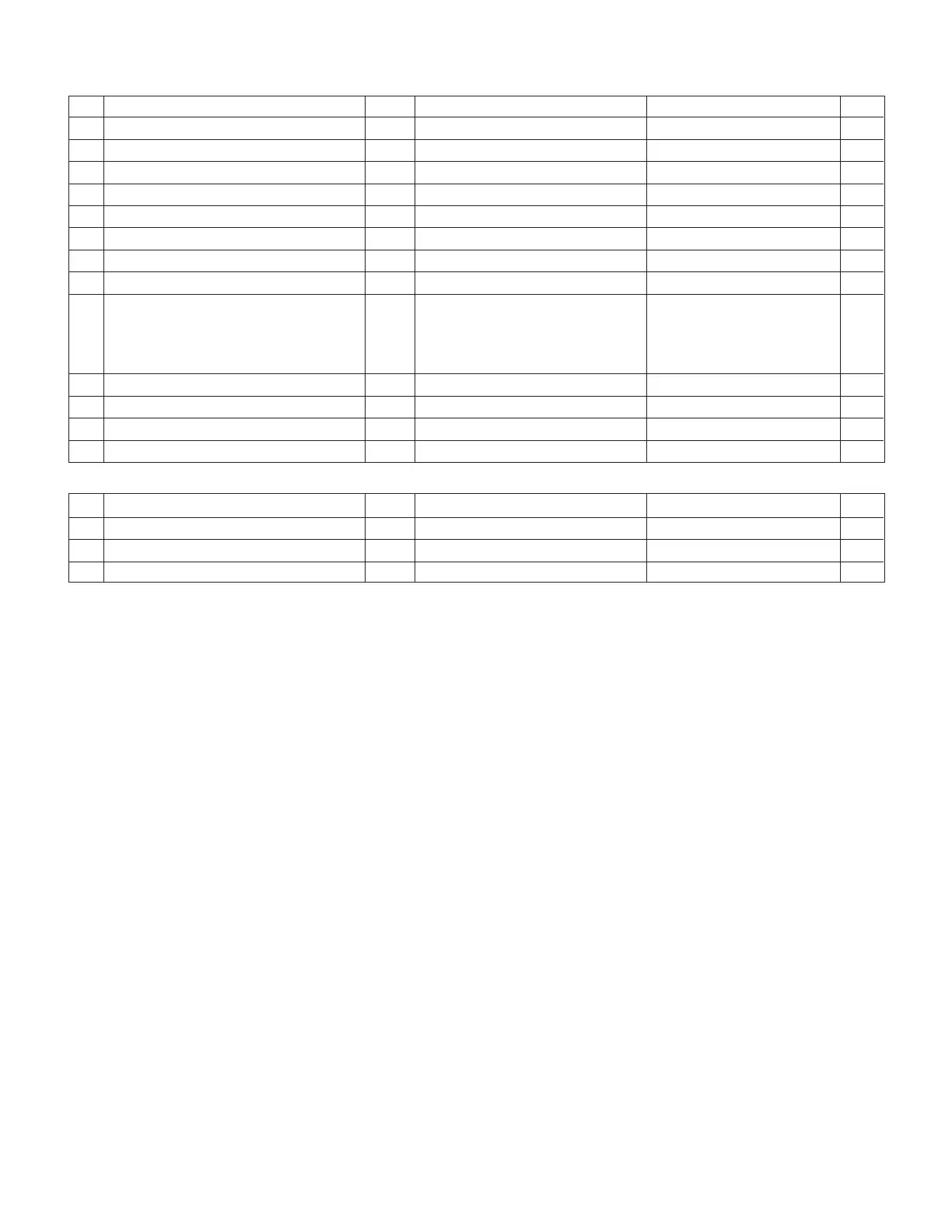

Ref. No. Part No. ★ Description Code Ref. No. Part No. ★ Description Code

16-22

VL-PD3S/H/E

VL-PD3S/H/E

VL-PD3S/H/E SERVICE JIG SPECIFICATIONS

1-1. Adjusting jigs for checking the mechanism

No. Name

New part

Type number, Application Part code Code

1 PB-use cassette torque meter 10g·cm/15g·cm 9DASD-1015 DB

2 Torque gauge

For use in VS-REW take up torque adjustment

JiGTG0045 CN

3 Torque gauge head For use with the above torque gauge 9EQTGH-DH5000 BW

4 Tension gauge 4N For measuring of pinch roller pressure JiGSG0400 BK

5 Dial tension gauge PTG-10 9DAPTG-10-10W CA

6 Torque screwdriver (1.5kg·cm) No. 0 cross bit JiGTD1500RTDH CB

7 Master plane For checking the reel base height 9EQMP-VLPD1 CL

8 Height adjustment jig (a set of 2 pcs.) For height adjusting 9DAHG-PD1 BZ

9 Height adjustment screwdriver For S guide adjustment. 9EQDRiVER-DH5 BC

For guide roller adjustment.

For Tu guide adjustment.

For T roller adjustment.

Bit shape (see figure below).

10 Alignment tape - I For tape running adjustment VR3-GAZXS CF

11 Alignment tape - II N For Switching Point adjustment VR3-JPZQS

12 Reel hub for back tension measurement Refer to Service Manual. Prepared in the service station. –

13 String for measuring the pinch roller pressure Refer to Service Manual. Prepared in the service station. –

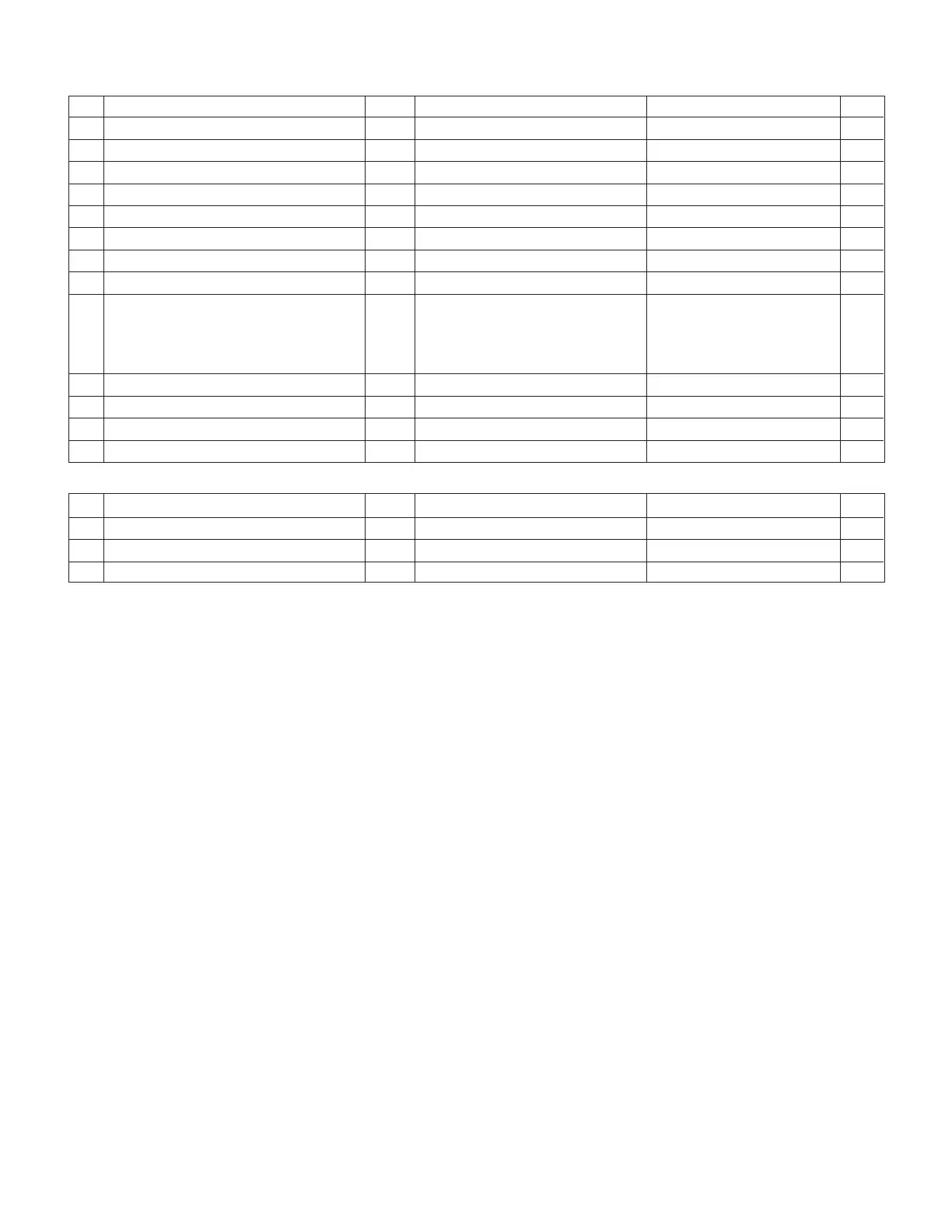

1-2. Parts for periodical inspection and maintenance

No. Name

New part

Type number, Application Part code Code

1 OiL Cosumo Hydro HV22 9EQ-OiL-HV22 AE

2 Cleaning paper Dusper ∑ (SIGMA) ozu Co., LTD JiGDUSPER AP

3 Grease: Moly Coat YM-103 Dow coaning 99FGREASE-YM103 AH

Loading...

Loading...