VL-PD3S/H/E

VL-PD3S/H/E

5-1

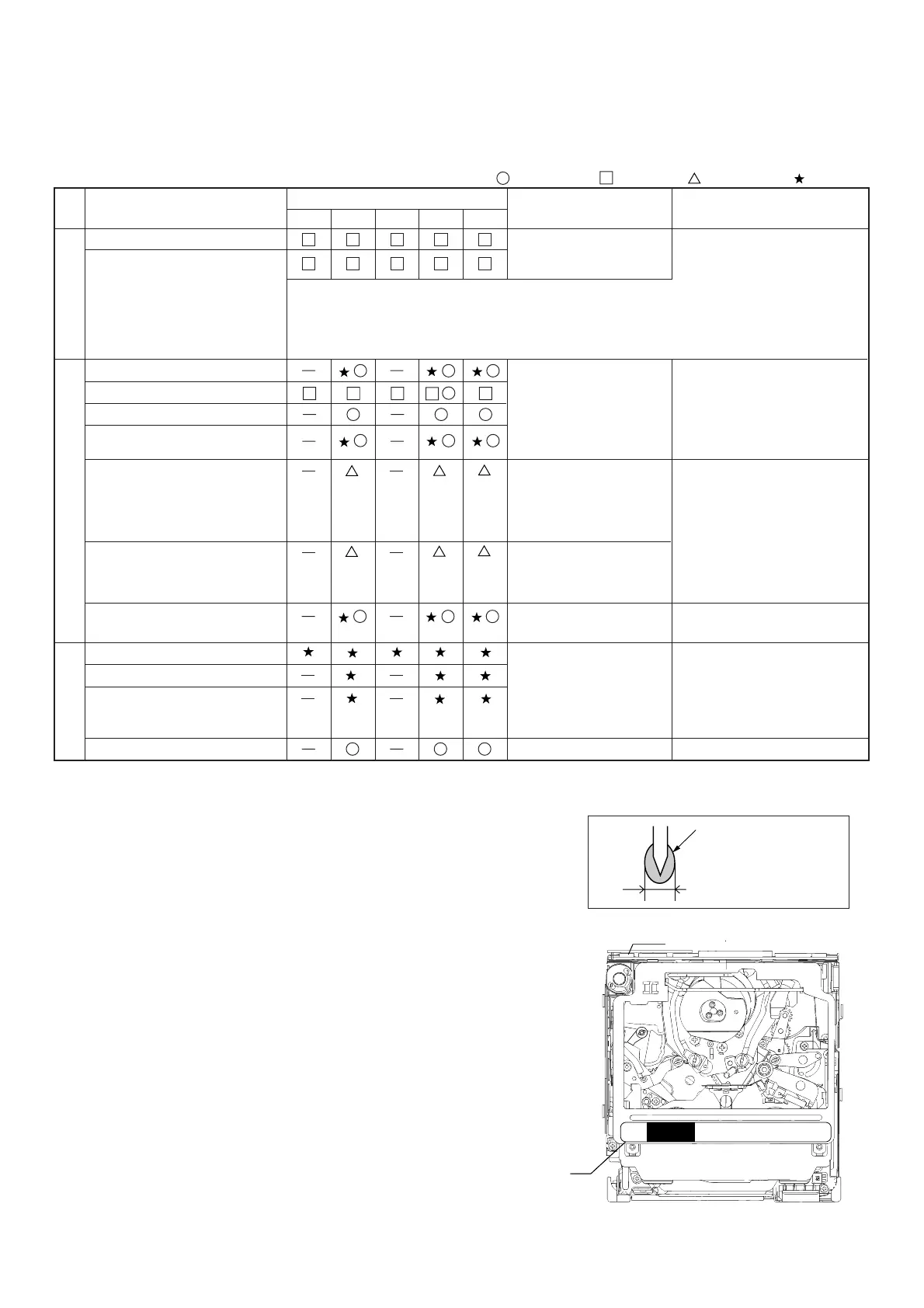

5. INSPECTION AND MAINTENANCE ITEMS AND INTERVALS

In order to keep the mechanical section always in good condition, perform the following inspection and maintenance at regular intervals.

In addition, after repair, perform the following maintenance items regardless of how long the user has been using the unit.

5-1. List of inspection and maintenance items

Inspection and

Time of use (h)

Symptoms that indicate Remarks

maintenance location

500 1,000 1,500 2,000 3,000

need for maintenance

Tape running section (see section 7-3)

Drum section, Video head

(see section 7-3)

• Block-type noise

• Head hole clogging

• Tape damage

<Rollers>

• Replace if there is anything abnormal in the rotation, or if there is run-out

(that becomes large).

<Other than the above>

• Clean the section that contacts the tape (especially the lower drum helical

section). Use the specified cleaning liquid.

• The tape fails to run.

• The tape becomes slack.

• Block-type noise

• Abnormal noise

Timing belt

Pinch roller

Capstan motor

• Replace if there is anything

abnormal.

Swing arm

S reel base, Tu reel base

Center pulley shaft

Intermediate pulley shaft

Swing arm boss

Intermediate gear A shaft,

Intermediate gear B shaft

Tension-arm shaft

• Tape damage

• Abnormal played-back

image

Loading motor

Mode switch

• Cannot eject.

• Fails to enter a mode.

Drive system

• The tape fails to run.

• The tape becomes slack.

• Tape damage

• The play-back image is

abnormal.

Abnormal noise

PB · VS/REW winding torque

PB · VS/R · loading back tension

Tu reel base ratchet torque

S reel base no-load torque

AHC

Performance checks

Tape running system

• • • Replace. • • • Clean. • • • Lubricate. • • • Check.

Note:

Replace the drum ass'y if the

video head is cleaned but the

envelope is not still appeared.

(When the envelope is normal,

refer to "10. USEFUL TIPS".)

• Replace any part that fails to

perform within the standard.

• Replace if anything is abnormal

(including the noise).

• Lubricate with oil.

[Oil]

Cosmo Hydro HV22

.... Excepting intermediate

gear A and B

Cosmo Hydro HV100

.... Intermediate gear A and B

Note:

Apply oil to the shaft, then

wipe lightly with a cloth.

• Abnormal noise

[Screw lock] Three Bond 1401B

[Cleaning liquid] Industrial-use ethyl alcohol

[Oil] Cosmo Hydro HV22, HV100

[Grease] Moly Coat YM-103

5-2. Precautions

(1)When replacing any part, always replace the cut washer that was

removed with a new one.

(2)This mechanism does not have control adjustment. If the control cannot

be set as required, clean and or replace parts.

(3)On the oil

a) Always use the specified oil. (Using another kind of oil can cause

various kinds of trouble.)

b) Always use clean oil, without any mixed-in dirt, to lubricate bearings.

(Using oil with dirt mixed in can cause the bearings to wear or to stick.)

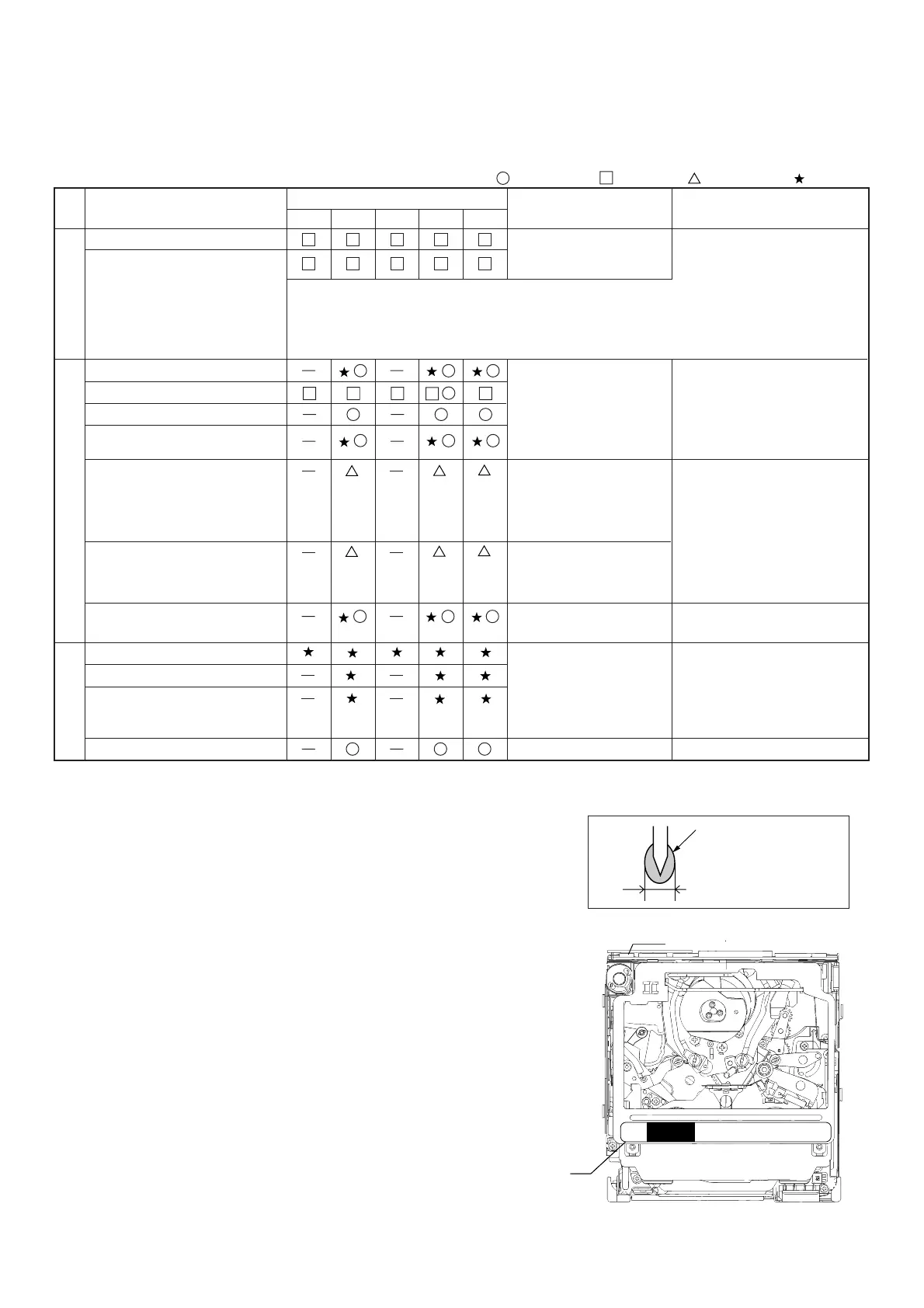

c) One drop of oil is the amount shown in the Fig. 1, on the point of a pin.

(4)Perform circuit repair, tape running adjustment, etc. with the cassette

controller assembly attached to the mechanism.

(5)To operate the mechanical section alone, remove the FPC of loading motor

from the connector (section B in the Fig. 2), and apply voltage to the loading

motor to drive it. The voltage between terminals must be DC3V or less.

(Forcing the gears to turn by hand entails danger of breakage.)

(6)To install the cassette controller, push section A in the Fig. 2. Do not push

anything else.

(7)Do not deform any of the mechanical parts.

1.5mm diameter or less

Oil

Fig. 1

Fig. 2

PUSH

B

A

Loading...

Loading...