19

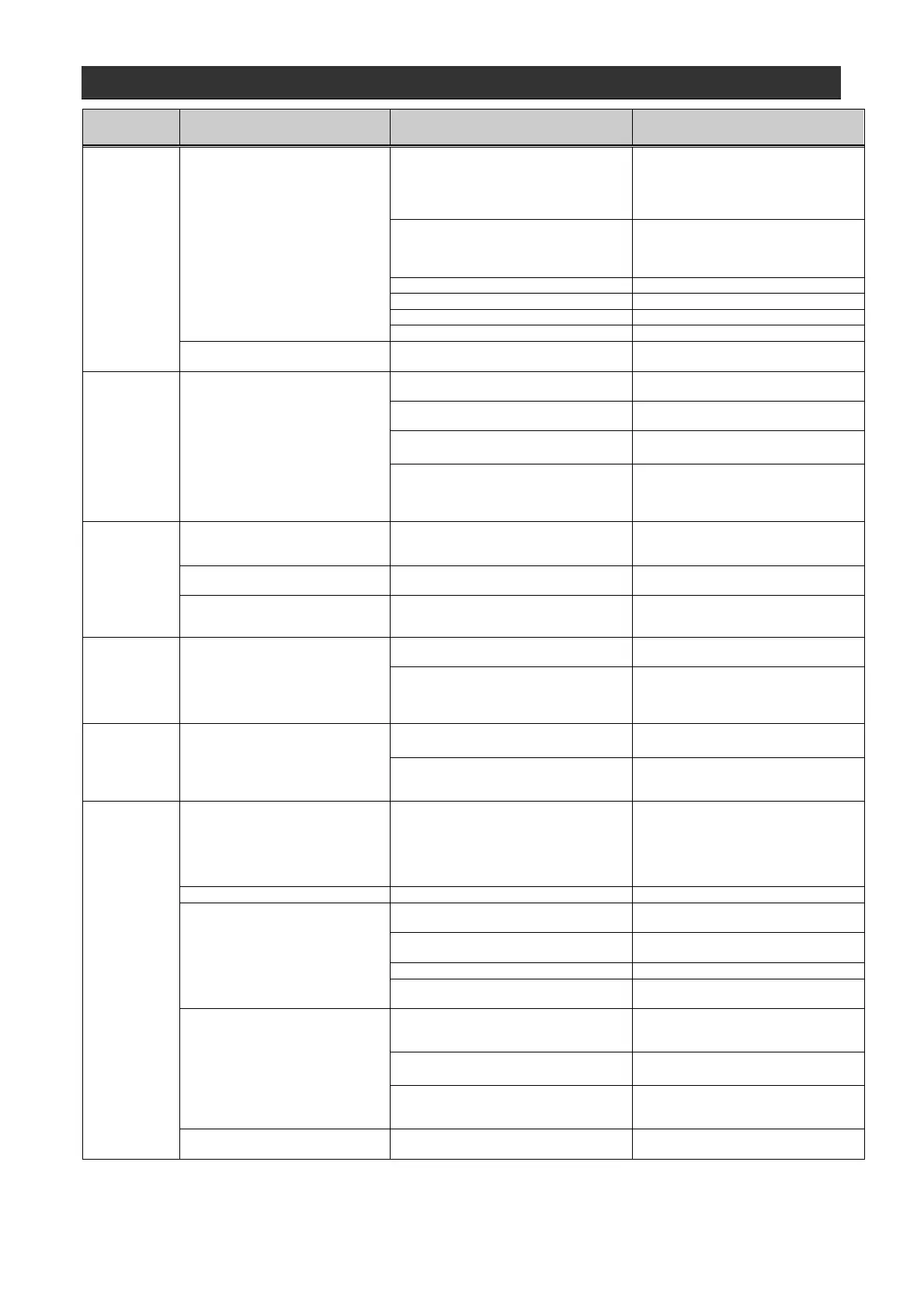

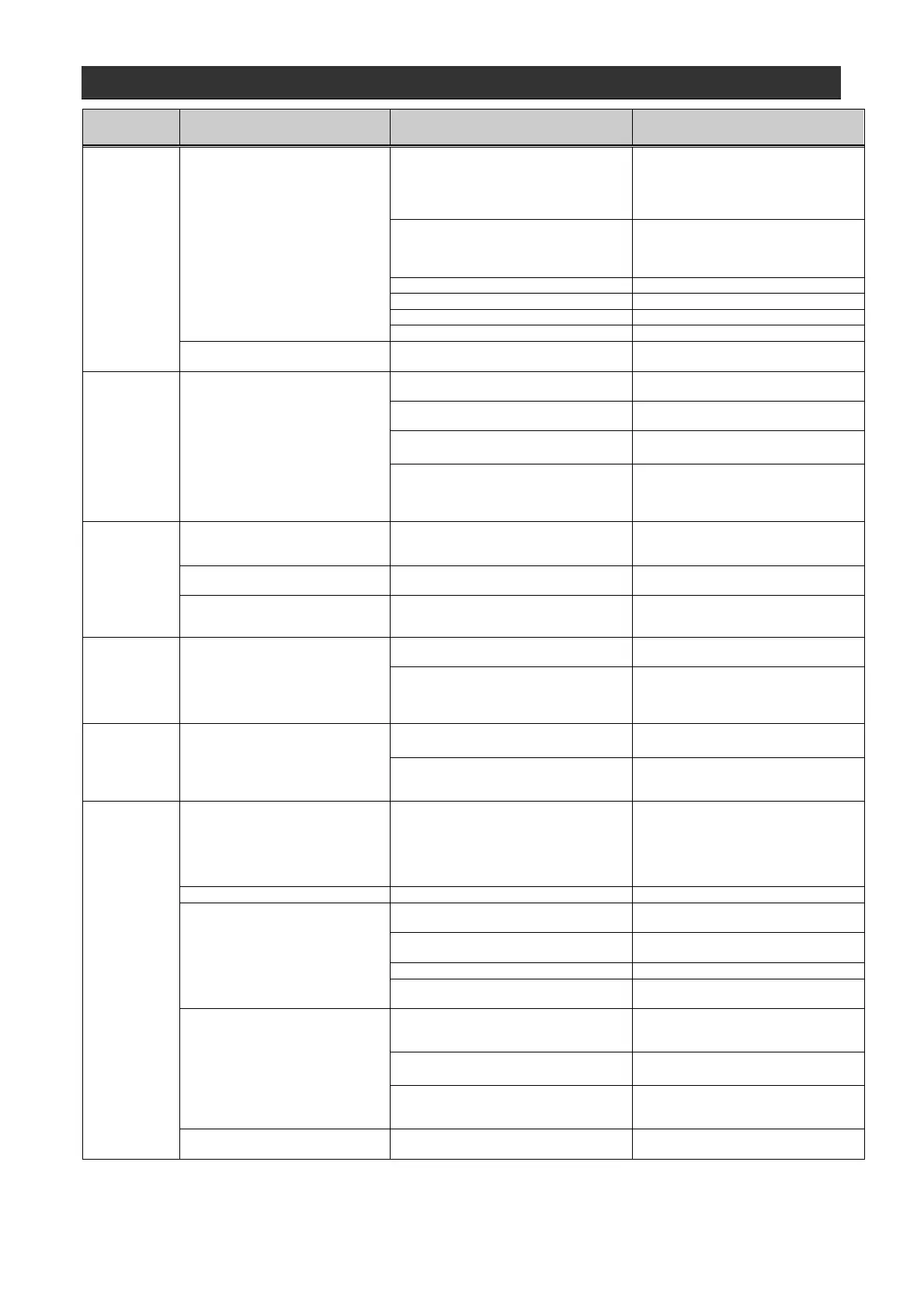

13. TROUBLESHOOTING

Trouble What to do first Possible Causes Countermeasures

The drill motor

does not start.

(1) Turn off the main switch.

(2) Turn off the PRCD (220-240V)

and unplug the drill motor from

the power supply.

Fault in the electric supply Plug the drill motor into another power

supply and check whether the drill

motor works. Check the extension cord,

RCD/GFCI/PRCD, power supply, and

the outlet. Replace them if necessary.

Other power tools are plugged into the

power supply.

Disconnect the other power tools from

the power supply. Secure at least 4.0

kVA (100 V), 3.5 kVA (110-120V) or 5.2

kVA (220-240V) for the drill motor.

The power cable/plug is damaged. Contact a Shibuya authorized dealer.

The main switch is damaged. Contact a Shibuya authorized dealer.

The armature/field coil is damaged. Contact a Shibuya authorized dealer.

The carbon brushes are worn out. Replace the carbon brushes.

(1) Turn off the main switch.

(2) Check the PRCD (220-240V).

The PRCD is turned off. Turn on the PRCD.

The motor runs,

but the core bit

does not

revolve well /

abnormal

noises.

(1) Turn off the main switch.

(2) Turn off the PRCD (220-240V)

and unplug the drill motor from

the power supply.

(3) Check that the gear change

knob is shifted properly.

(4) Check the core bit.

The gear change knob is not shifted

properly.

Shift the gear change knob to engage

gears properly.

The clutch is worn or loose. Contact a Shibuya authorized dealer.

Gears are worn or damaged. Contact a Shibuya authorized dealer.

Fragments of working materials such as

rebar, concrete, stones are jammed

between the core bit and the drilled

material.

Remove the concrete core from the

core bit.

The drill motor

shuts off during

the operation.

(1) Check whether the circuit

protector tripped.

If the circuit protector tripped, the drill

motor was overloaded due to apply too

much feed pressure.

Restart the drilling, and take care not to

apply too much feed pressure.

(2) Check whether the PRCD

tripped (220-240V).

If the PRCD tripped, electric leakage was

detected or voltage was dropped.

Contact a Shibuya authorized dealer, or

an electrical engineer.

(3) Unplug the drill motor from the

power supply.

Electric power failure Check the electric supply with electrical

engineer.

Water leaks

from the water

leakage hole /

swivel ring /

spindle shaft.

(1) Turn off the main switch.

(2) Turn off the PRCD (220-240V)

and unplug the drill motor from

the power supply. DO NOT

TOUCH THE POWER PLUG

WITH WET HANDS.

Oil seals are worn. Contact a Shibuya authorized dealer.

Water pressure is too high. Reduce the water pressure to less than

3 bar.

The core bit

can not be

attached to the

spindle.

(1) Check the core bit threads and

the spindle threads.

The core bit thread is blocked with dirt or

damaged.

Clean the thread, or replace the bit if

necessary.

The spindle thread is blocked with dirt or

damaged.

Clean the thread. If the spindle was

damaged, contact a Shibuya authorized

dealer.

Drilling

performance

goes down

(1) Turn off the main switch.

(2) Turn off the PRCD (220-240V)

and unplug the drill motor from

the power supply.

(3) Check the drainage water from

the drilling hole.

If the water contains iron powders, the

machine is cutting the rebar(s).

Restart the drilling, and take care not to

apply too much feeding pressure.

(4) Check the water supply Insufficient coolant water Increase the amount of water supply.

(5) Check the core bit.

The core bit is worn out, damaged, or

defected.

Replace with a new core bit.

The core bit segments are glazed. Contact the core bit seller to ask proper

sharpening methods.

Aggregate of concrete is too hard. Use a core bit with softer segments.

Maximum drilling depth is reached. Remove the core and use an extension

bar for core bits.

(6) Jolt the drill motor / stand / core

bit to see if it shakes.

The base is not securely fixed to the

working material.

Set up the machine again. Redo

anchoring securely / Adjust the leveling

bolts properly.

There is play between the carriage block

and the column.

Adjust the carriage block.

Screws which are fastening the base and

column, the carriage block and motor are

loosened.

Tighten the screws.

(7) Check for the axial runout of the

spindle.

Axial runout of the spindle is observed.

Contact a Shibuya authorized dealer.

Loading...

Loading...