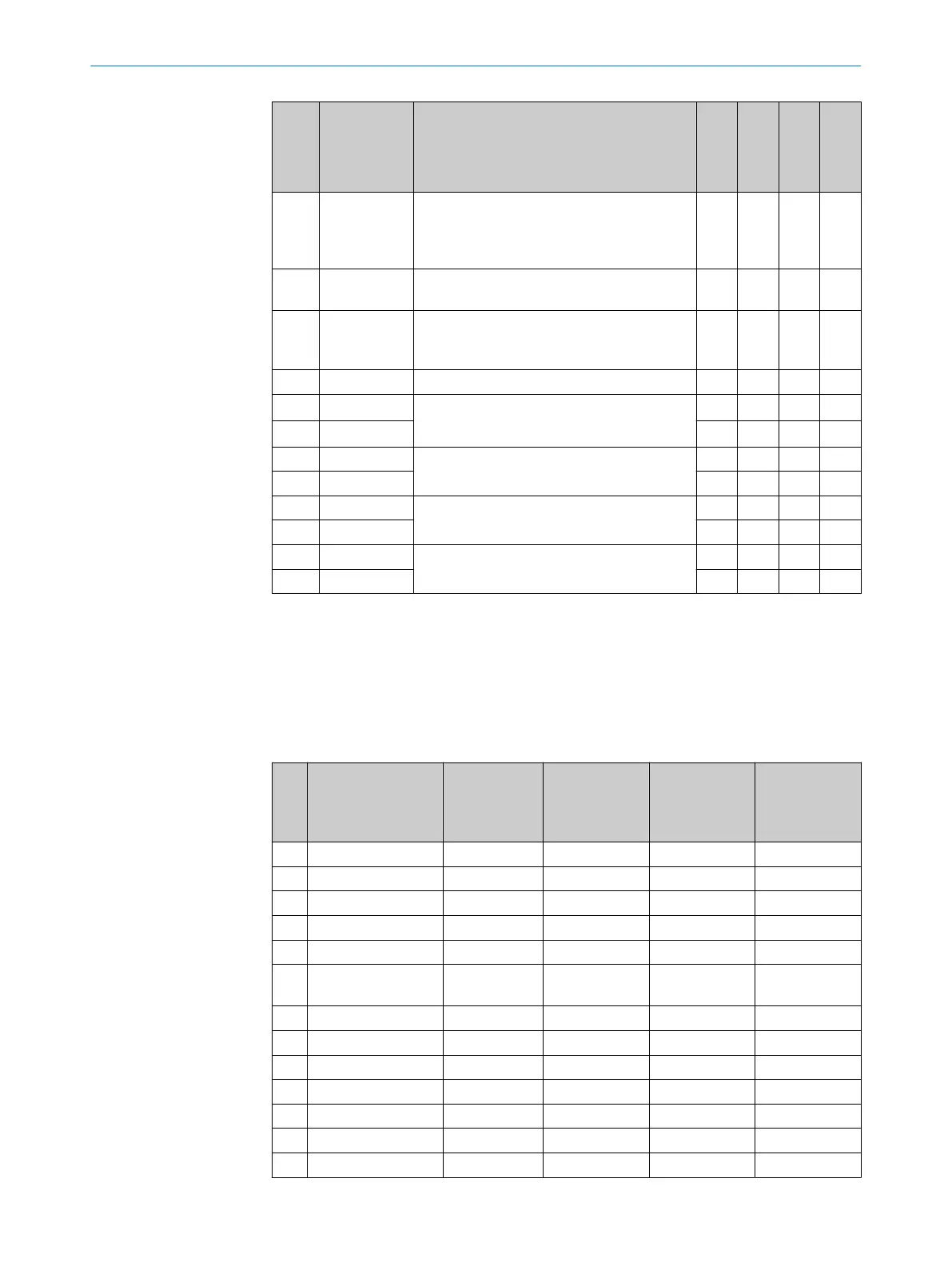

Pin Signal Function

Standard

Advanced

Professional

Expert

13 UNI-I/O3 /

ERR/WEAK

Universal I/O or application diagnostic out‐

put for error or contamination

or connection for a jumper for addressing as

guest

1)

C C C C

14 UNI-I/

O4 / W

F

Universal I/O or application diagnostic out‐

put for object in the warning field

C C C C

15 UNI-I/

O5 / RES_RE

Q/C2

Universal I/O or application diagnostic out‐

put, reset required, or (for the S300 Profes‐

sional and Expert) static control input C

C C C C

16 STBY Control input for standby mode

C C C C

17 EFI

A

Enhanced function interface = safe SICK

de

vice communication

C C C C

18 EFI

B

C C C C

19 24 V DC

Supply voltage

for incremental encoder 1

C C

20 GND

C C

21 24 V DC

Supply voltage

f

or incremental encoder 2

C C

22 GND

C C

23 TxD–

RS-422 interface to measurement data out‐

put

C C C C

24 TxD+

C C C C

1)

In order to operate 2 safety laser scanners in an EFI system, you must define a device as a guest using a

br

idge between pin 7 and pin 13.

2)

No dynamic control input.

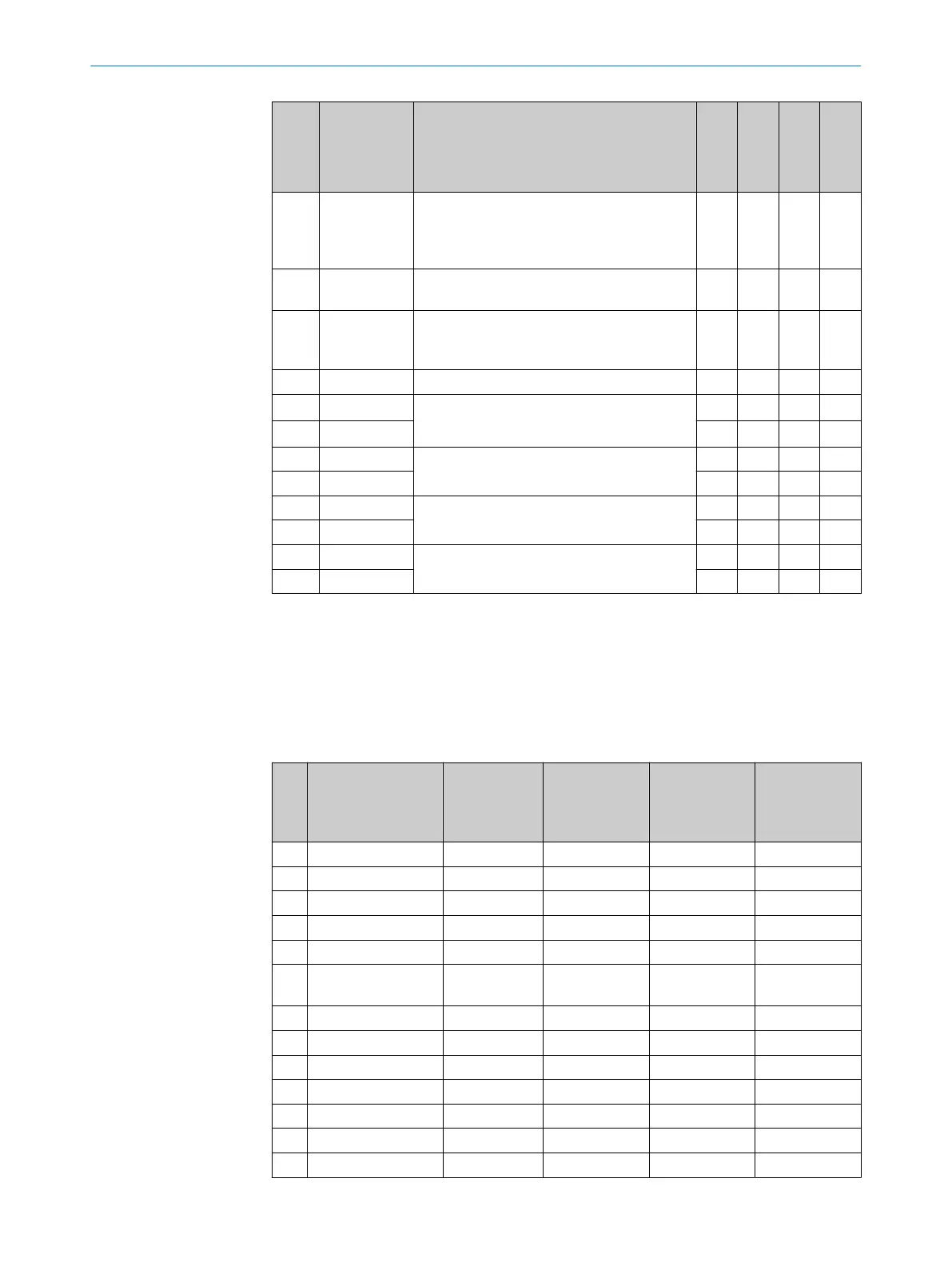

6 Pre-assembled system plug

Pre-assembled system plug with flying leads

P

in assignment on pre-assembled system plugs

Pin Signal Wire color SX0B-B1105G

SX0B-B1110G

SX0B-B1114G

SX0B-B1120G

SX0B-B1105J

SX0B-B1110J

SX0B-B1505G

SX0B-B1510G

FE Functional earth Green

C C C

1 24 V DC Brown

C C C

2 0 V DC Blue

C C C

3 OSSD1 Gray

C C C

4 OSSD2 Pink

C C C

5 UNI-I/O1 / RESET/

C1

Red

C C C

6 UNI-I/O2 / EDM Yellow

C C C

7 A1 or INC1_0 White/blue

C

8 A2 or INC1_90 White/gray

C

9 B1 or INC2_0 White/violet

C

10 B2 or INC2_90 White

C

13 UNI-I/O3 / ERR White/black

C C C

14 UNI-I/O4 / WF White/brown

C C C

MOUNTING INSTRUCTIONS

8025883/2020-08-31 | SICK M O U N T I N G I N S T R U C T I O N S | S300

11

Subject to change without notice

Loading...

Loading...