Do you have a question about the SICK UE410-8DI and is the answer not in the manual?

Defines the requirements and qualifications for personnel responsible for mounting, commissioning, and servicing the safety controller.

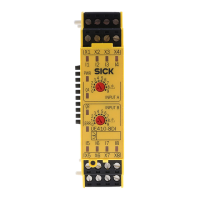

Describes the configurable control system for safety applications and its compliance with safety standards like EN ISO 13849-1 and IEC 61508.

Specifies the intended use of the Flexi Classic modular safety controller and the conditions under which warranty claims are void.

Provides essential safety guidelines, directives, and protective measures to ensure safe installation and operation of the system.

Highlights the modular concept, compact width, plug-in style, and system expansion capabilities of the Flexi Classic series.

Explains the system architecture, including main modules, extension modules, and gateways that form a Flexi Classic system.

Details the UE410-MU's role as the primary module, controlling up to two applications and storing system configuration.

Details the 9 settable programs for UE410-MU/XU modules, defining sensor types and logic instructions.

Lists the 9 programs for the UE410-GU, detailing global and local emergency stop functions and reset modes.

Details the implementation of two-hand operation and jog mode functions using specific programs and inputs.

Describes the muting function, its purpose in overriding safety devices for material transport, and safety notes.

Explains the bypass function, its limited duration, and the safety precautions required during its operation.

Details the use of control inputs S1, S2, and S3 for configuring functions like restart interlock, retriggering, and EDM.

Provides step-by-step instructions for physically mounting the Flexi Classic modules onto a DIN mounting rail.

Details the procedure for safely removing modules from the DIN mounting rail, including disconnecting terminals.

Describes the process of validating the system's safety functions and ensuring compliance with performance levels and standards.

Outlines the procedures for initial commissioning tests and regular system testing to maintain safety integrity.

Explains the procedure for setting module configurations, including using rotary switches and the ENTER button for saving settings.

Provides guidance on how to cease operation and perform functional tests when malfunctions or errors occur.

Lists the available Flexi Classic modules, their part numbers, and key features like inputs, outputs, and delay options.

| Brand | SICK |

|---|---|

| Model | UE410-8DI |

| Category | Controller |

| Language | English |