Do you have a question about the SICK FX0-GMOD and is the answer not in the manual?

Provides crucial safety guidelines for product integration, mounting, and electrical installation to prevent hazards.

Specifies the authorized applications and standards for the Flexi Soft controller, outlining limitations and warranty conditions.

Details the necessary expertise and qualifications for personnel involved in the product's lifecycle: planning, installation, configuration, and operation.

Outlines the key features of the Flexi Soft system, including modular design, input/output capacity, and network integration.

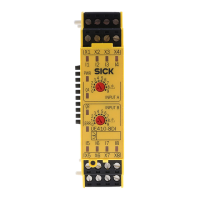

Lists and categorizes the various modules available for the Flexi Soft system, such as main, expansion, and relay modules.

Provides step-by-step instructions for safely and correctly mounting the Flexi Soft modules on a DIN rail.

Outlines critical safety requirements, standards, and precautions for electrical installation to prevent hazards.

Details the pin assignments and functions of terminals for various Flexi Soft modules, aiding in correct wiring.

Describes the prerequisites and process for configuring the safety controller using specialized software and system plugs.

Outlines the procedures and checks required for the overall acceptance of the application before final operation.

Lists essential checks to perform before the initial commissioning of the machine and safety controller.

Outlines the mandatory periodic checks for safety functions by qualified personnel to ensure ongoing system integrity.

Provides instructions and considerations for safely replacing modules to maintain system operation and safety.

Describes how to respond to malfunctions and errors to ensure the safety of the plant and machine.

Explains the different error states (Configuration, Remediable, Serious) indicated by module LEDs.

Explains how to calculate response times considering all system paths, including fast shut-off functions.

| Fieldbus interface | PROFIBUS DP |

|---|---|

| Relative humidity | 95 %, non-condensing |

| Protection class | IP20 |

| Function | Gateway |

| Supply voltage | 24 V DC |

| Operating temperature | 0 °C ... +50 °C |

| Storage temperature | –25 °C ... +70 °C |

| Communication interface | RS485 |

| Baud rate | 9.6 kbit/s ... 12 Mbit/s |

| Protocols | PROFIBUS DP |