AC MUM0040 rev. 11 - 22 -

MR12 - MR12C

15.1. PRE-ADJUSTMENT OF THE BRAKE

The winches are normally supplied with the brake that requires

some adjustment based on the characteriscs of the system. The

braking distance depends on the compression of the brake’s springs;

the springs need to be adjusted to obtain the braking torque of the

braking system that is suitable for the system, and in compliance with

EN81.20-50 (See chart).

If an addional adjustment is required, follow the instrucons

reported in the following chapter.

15.2. BRAKE ADJUSTMENT

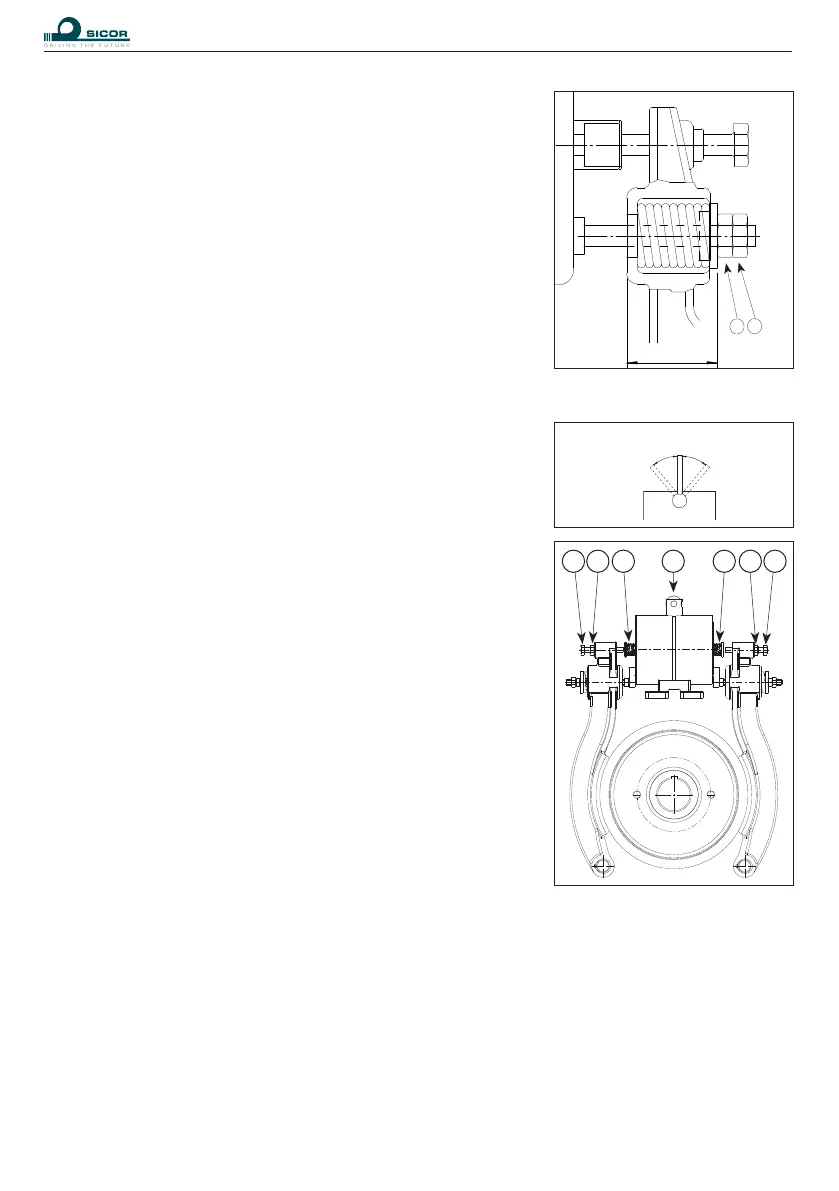

The brake has two separate magnets so that the shoes operate

independently of each other.

Usually the brake shoes must open with the shortest stroke possible,

but without showing any fricon on the brake’s drum under the

normal winch working condion.

Check periodically the status of wearing of the brake’s shoes’ fricon

material. In case of wear, proceed with the adjustment operaons in

compliance with what’s provided in the following chapters.

During each adjustment intervenon, make sure that between the

opened brake’s shoe (winch free to rotate) there’s a space equal to

0.1-0.15 mm in the lining’s lower part, by verifying with a calibrated

spacer.

1 2 5 6 2 15

“OPEN”

“OPEN”

“CLOSED”

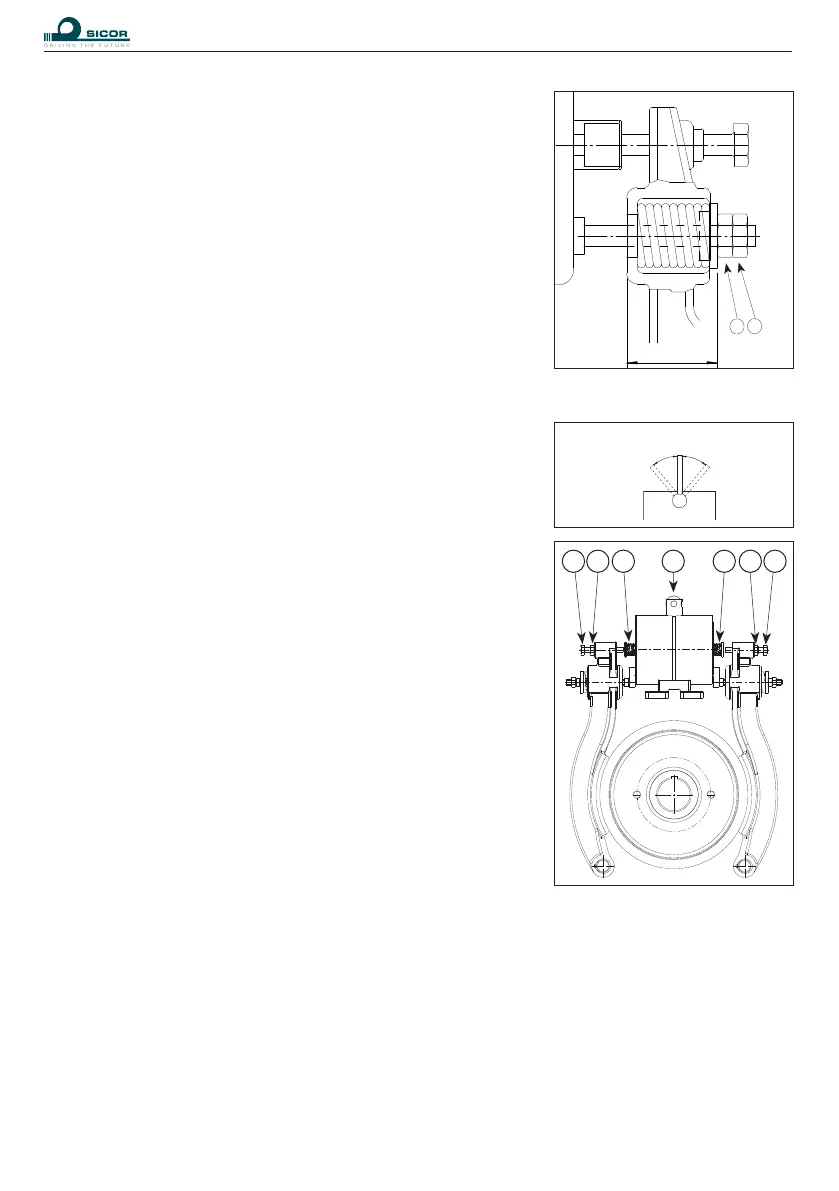

15.2.1. STROKE ADJUSTMENT

- Loosen the locknuts (2) on both the brake shoes and unscrew the

adjusng screw (1) leaving a clearance of 4-5 mm between the

screw and the electromagnet pin (5),

- turn the brake opening lever (6) to the “open” posion,

- ghten the adjusng screws (1) by hand unl they are ush with

the electromagnet pin (5),

- turn the brake opening lever (6) to the “closed” posion and ghten the adjusng screw half a turn

(equal to about 0.1-0.15 mm in the lining’s lower part) against the electromagnet pin,

- ghten the locknuts (2).

15.2.2. CHECKING THE ADJUSTMENT

Move the cab up and down and listen to the noise level. The stroke is correctly adjusted if the brake

lining does not touch the brake drum while the li is moving and no noise is heard when braking.

4

3

L = 59mm

Loading...

Loading...