Commissioning

4.2 Commissioning with BOP-2 operator panel

CU240B-2 and CU240E-2 Control Units

Compact Operating Instructions, 01/2017, A5E39910322B AA

21

When selecting an application class, the inverter assigns the appropriate default settings to

the motor control:

●

Standard Drive Control (Page 22)

● Dynamic Drive Control (Page 24)

● EXPERT: This procedure is described in the operating instructions.

●

Overview of the manuals (Page 33)

Selecting a suitable application class

When selecting an application class, the inverter assigns the appropriate settings to the

motor control.

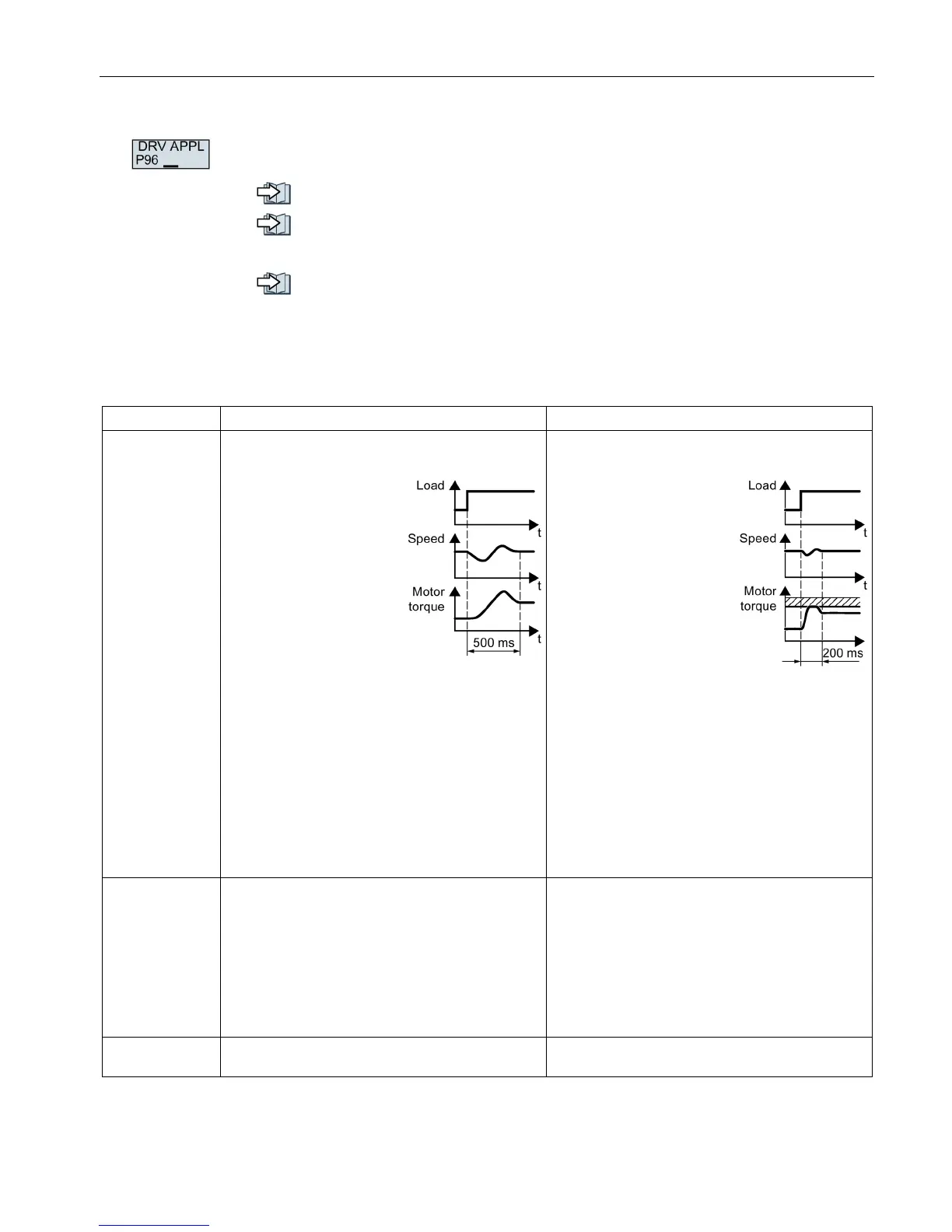

• Typical settling time after a speed change:

100 ms … 200 ms

• Typical settling time

after a sudden load

change: 500 ms

• Standard Drive

Control is suitable

for the following re-

quirements:

– Motor power

ratings < 45 kW

– Ramp-up time

0 → Rated speed (dependent on the rated

motor power): 1 s (0.1 kW) … 10 s (45 kW)

– Applications with constant load torque

without load surges

• Standard Drive Control is insensitive to inaccu-

rate motor data settings

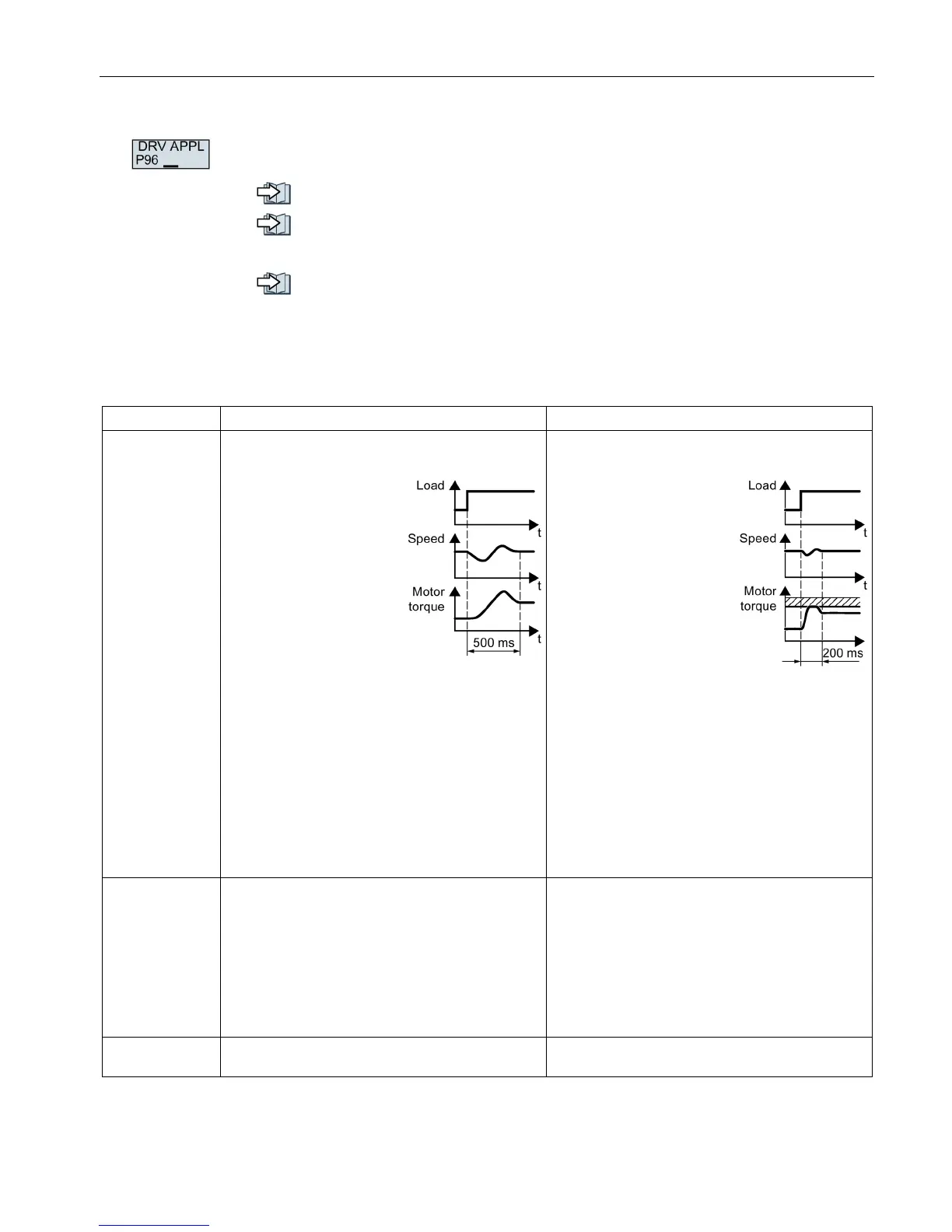

• Typical settling time after a speed change:

< 100 ms

• Typical settling time

after a sudden load

change: 200 ms

• Dynamic Drive Con-

trol controls and lim-

its the motor torque

• Torque accuracy

that can be

achieved: ± 5 % for

15 % … 100 % of

the rated speed

• We recommend Dynamic Drive Control for the

following applications:

– Motor power ratings > 11 kW

– For load surges of 10 % … >100 % of the

rated motor torque

• Dynamic Drive Control is necessary for a

ramp-up time 0 → rated speed (dependent on

the rated motor power):

< 1 s (0.1 kW) … < 10 s (132 kW).

• Pumps, fans, and compressors with flow char-

acteristic

• Wet or dry blasting technology

• Mills, mixers, kneaders, crushers, agitators

• Horizontal conveyor technology (conveyor

belts, roller conveyors, chain conveyors)

• Basic spindles

• Pumps and compressors with displacement

machines

• Rotary furnaces

• Extruder

• Centrifuge

Motors that can

be operated

Induction motors Induction and synchronous motors

Loading...

Loading...