16/17

Building Technologies CC1N7761en

HVAC Products 19.02.2007

Connection examples and sequence diagrams (cont’d)

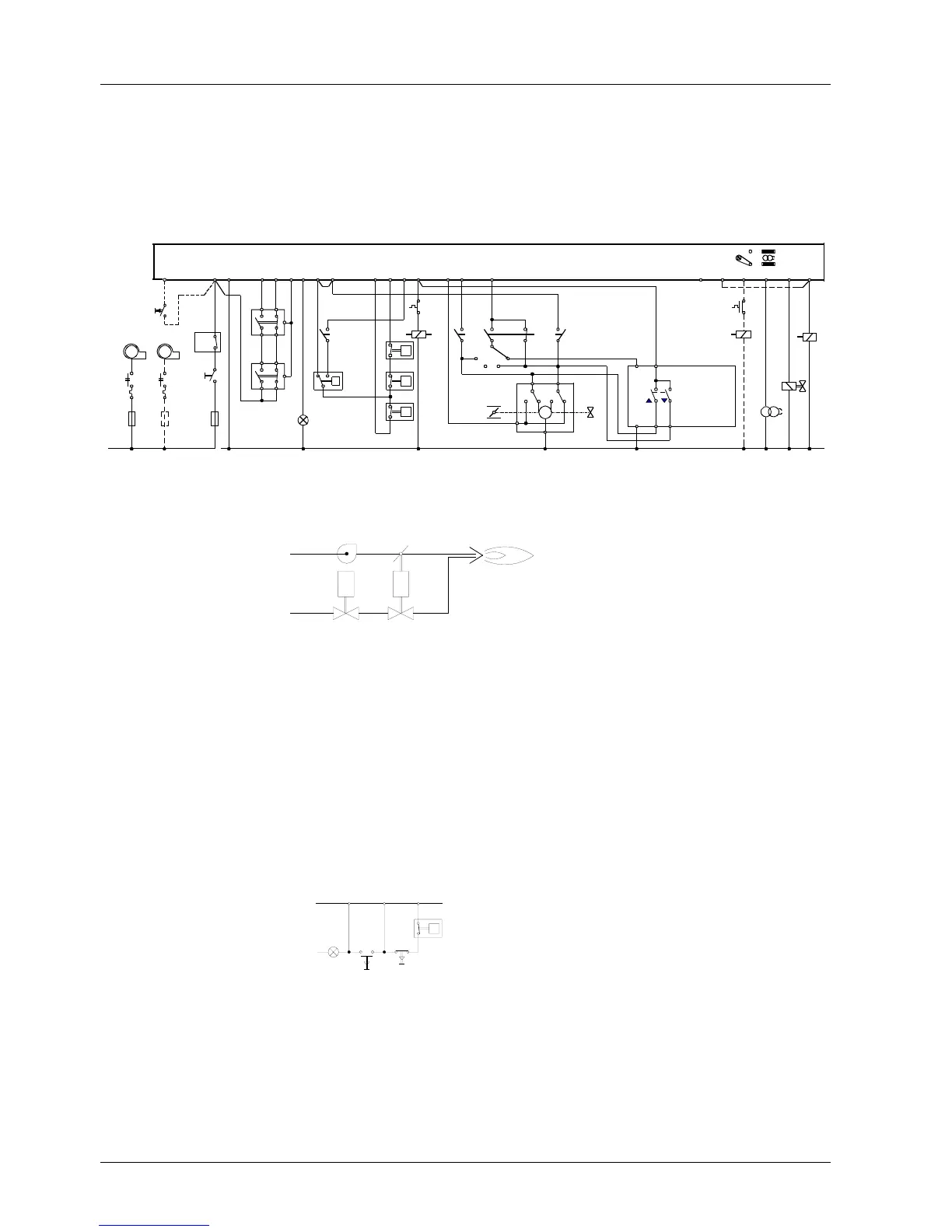

Double- or multiflame supervision of modulating burners

Including checked actuator control.

Required type of flame safeguards:

For oil LAE10 with active selenium photocell detectors RAR...

For gas LFE10 with UV detectors QRA... or ionization probe

For oil / gas LFE10 with UV detectors QRA...

1 2 13 14 15 12 19 18 8 9 4 3 20 22 21

d1c1

e1

c1

c1

10 11 17 6 5 7

e2

c2

d1

c1

H

M1

M2

MM

c1

e1

c2

e2

P

(R)

N

(Mp)

L2

P

LP

T

T

W

R

M

a

z

12

LK

11

12

N

RV

SQ...

Z

BV1

BS

I

II

III

IV

LEC1...

7761a10/0503

UL.2

EK2

16

3

7

4

5

6

FW

3

7

4

5

6

FW

(LAE10, LFE10)

P

GP

SB

**

*

RWF40

Q

L

NY1 Y2

* GP: Not required with oil burners

** LP: Recommended for oil burners, if the oil pump is not coupled to the fan motor

Operating switch BS1

I

Nominal load

II

Stop

III

Partial load

Air

Fuel

M

BV1

RV

SQ...

LK

7761a11e/0501

IV

Automatic control

Burners designed for continuous adjustment of the burner’s output (modulating burn-

ers) require the devices of the temperature or pressure control circuit, in addition to the

standard burner equipment, e.g.

1 Modulating controller RWF40...

1

Temperature or pressure sensor

QA... / QB...

1

Remote setting unit, if required

FZA...

1 Actuator for the control of the air damper and the fuel throughput

(fuel / air ratio control)

SQ...

1 Auxiliary relay d1

1 Operating switch BS

1 Control valve or similar for adjustment of the fuel throughput RV

18 8

9

L

N (Mp)

I

0

W

T

7761a07/0696

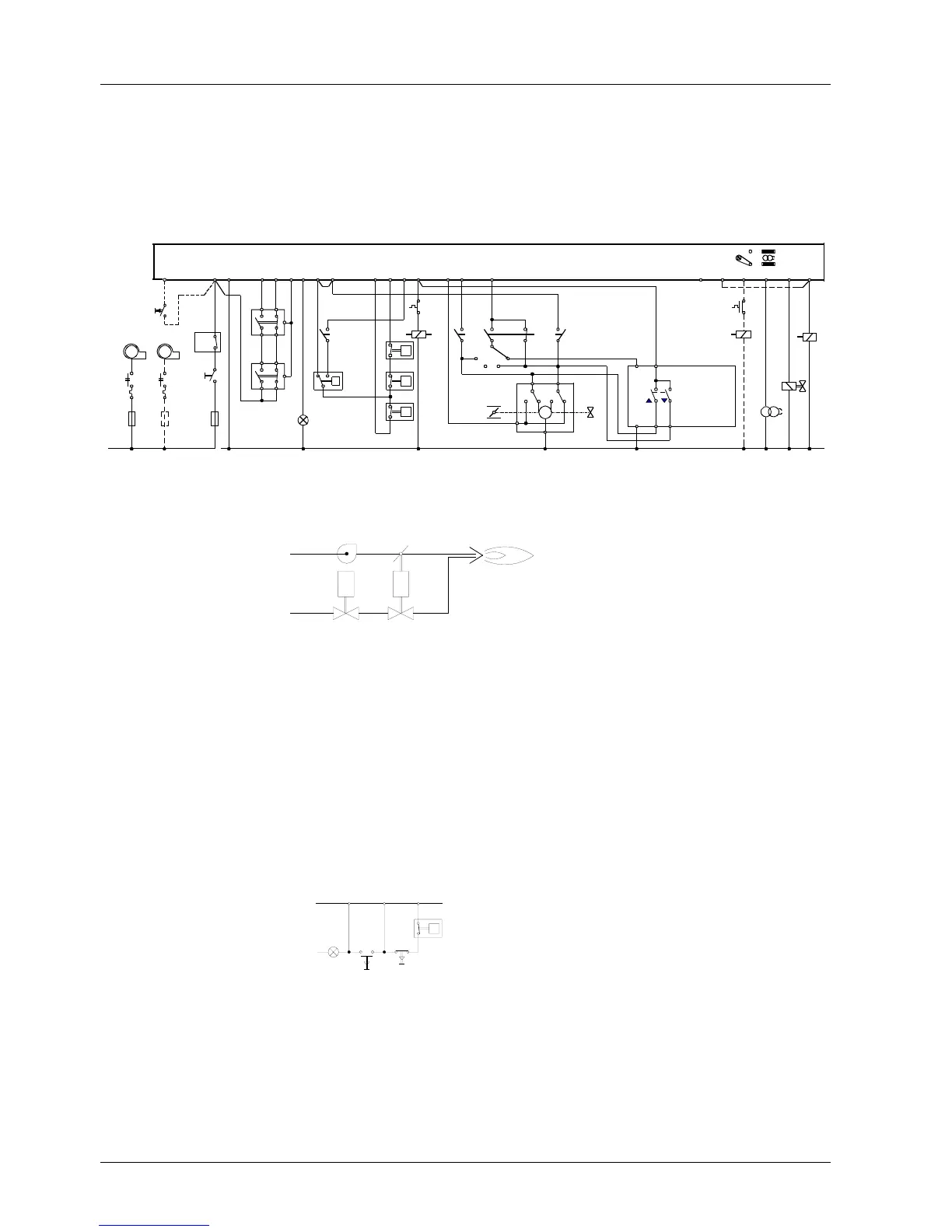

This circuit is used if, for certain reasons, fully automatic

operation is not required (e.g. with industrial burners).

The burner is started up by actuating impulse contact I; the

burner is shut down by either pressing circuit-breaking con-

tact 0 or when the limit thermostat cuts out.

Control for semiauto-

matic operating mode

Loading...

Loading...