Specifications continued…

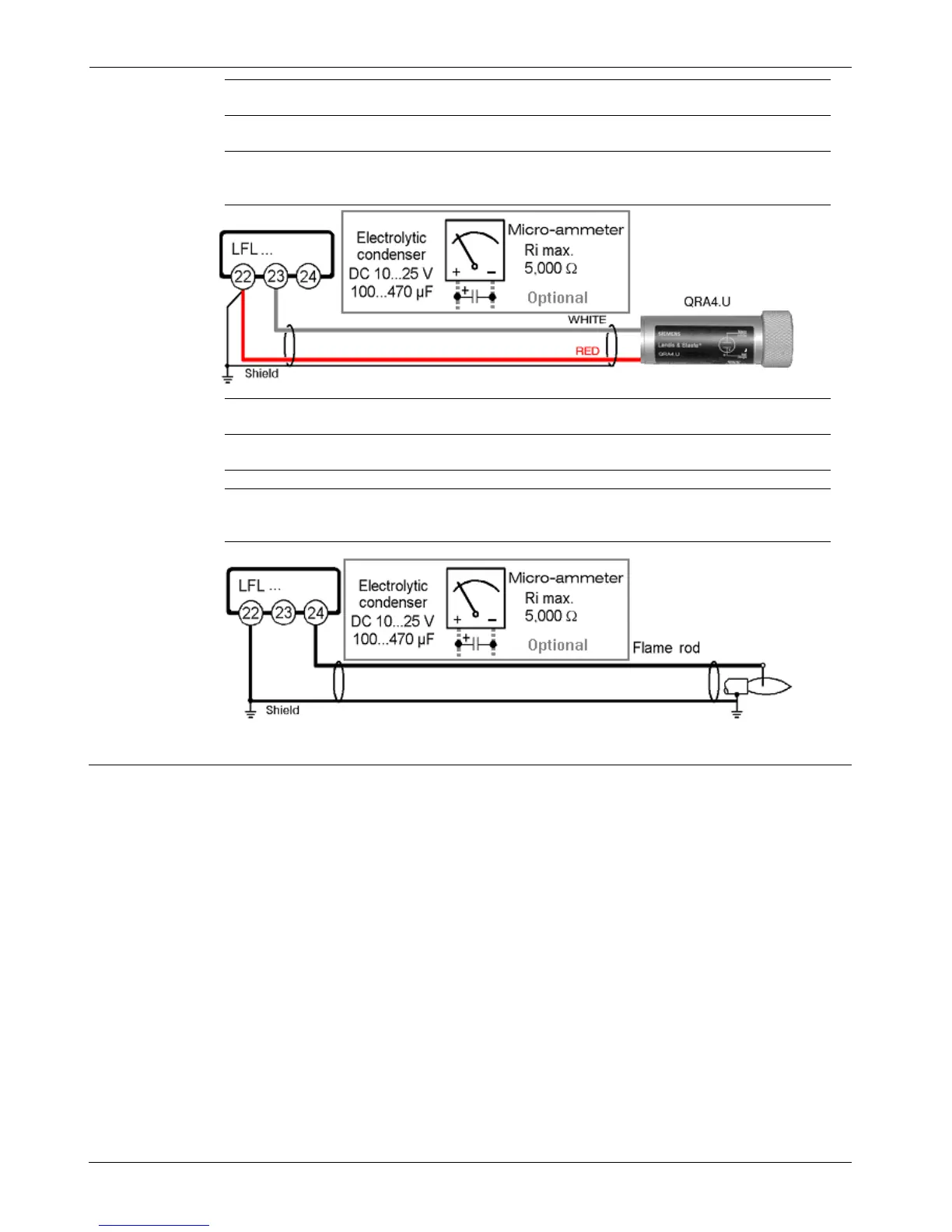

Voltage – during burner operation

Voltage – during start-up phase (flame circuit check)

330 Vac ±10 %

380 Vac ±10 %

Required minimum UV sensor signal

Typical UV sensor signal measurement

70 µA

100-450 µA

Length of detector cable (run in a separate conduit from all other wiring)

- Unshielded wire

- Shielded cable, shield grounded to terminal 22

max. 300 ft

max. 600 ft

Flame

supervision

with

UV sensor

QRA...

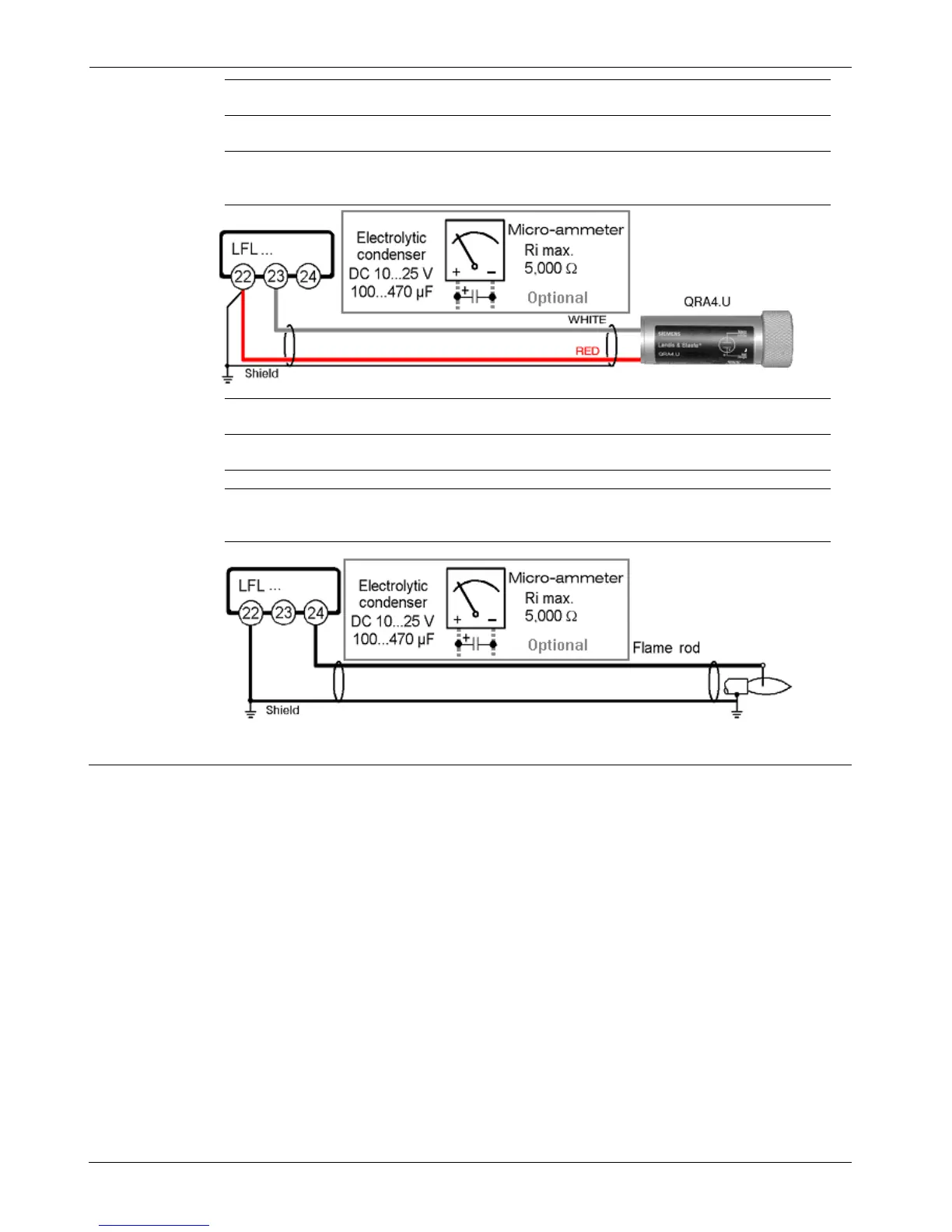

Voltage at the flame rod – during burner operation

Voltage at the flame rod – during start-up phase (flame circuit check)

330 Vac ±10 %

380 Vac ±10 %

Required minimum flame rod signal

Typical flame signal measurement

6 µA

20-100 µA

Short-circuit current max. 0.5 mA

Length of detector cable (run in a separate conduit from all other wiring)

- Unshielded wire

- Shielded cable, shield grounded to terminal 22

max. 250 ft

max. 500 ft

Flame

supervision

with

Flame rod

Electrical connection notes for flame supervision

• It is important to minimize electrical disturbance and signal loss.

• Run flame signal wiring separate from all other wiring

• Observe the length of detector cable as indicated above

• The flame rod does not provide protection from electric shock

• Locate the ignition electrode(s) and flame rod such that the ignition spark cannot arc to the

flame rod (risk of electrical overload and damage to flame supervision circuit)

• When using the QRA..., grounding of terminal 22 is required

• Multiple UV sensors QRA... and/or flame rods can be connected in parallel

• If separate flame sensors are used for pilot and main flame supervision,

an interrupted pilot must be utilized

5/12

Siemens Building Technologies CC1N7451en

HVAC Products 11.15.2004

Loading...

Loading...