.,........---~

""

I I

.....

fr

·

1 I

i

!

l

LUBRICATION

Page 20

CIRCUIT

BREAKER

LUBRICATING

INSTRUCTIONS

More

frequent inspections are recommended,

if

severe

load conditions, dust, moisture,

or

other

unfavorable

con-

ditions exist.

Periodic inspections

of

each circuit

breaker

is

recom-

mended at least once a year.

Always inspect a breaker

which

has interrupted a heavy

fault current.

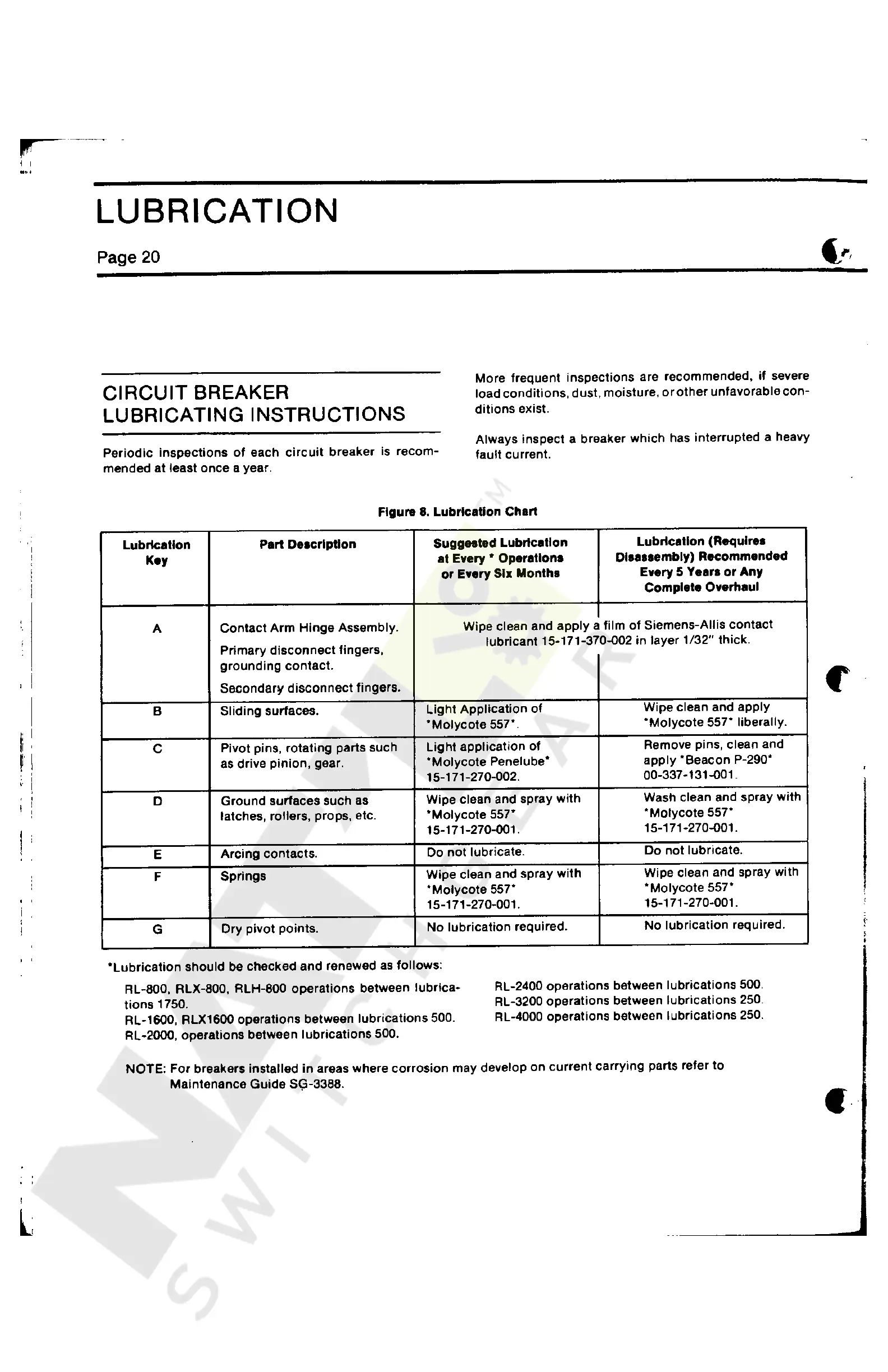

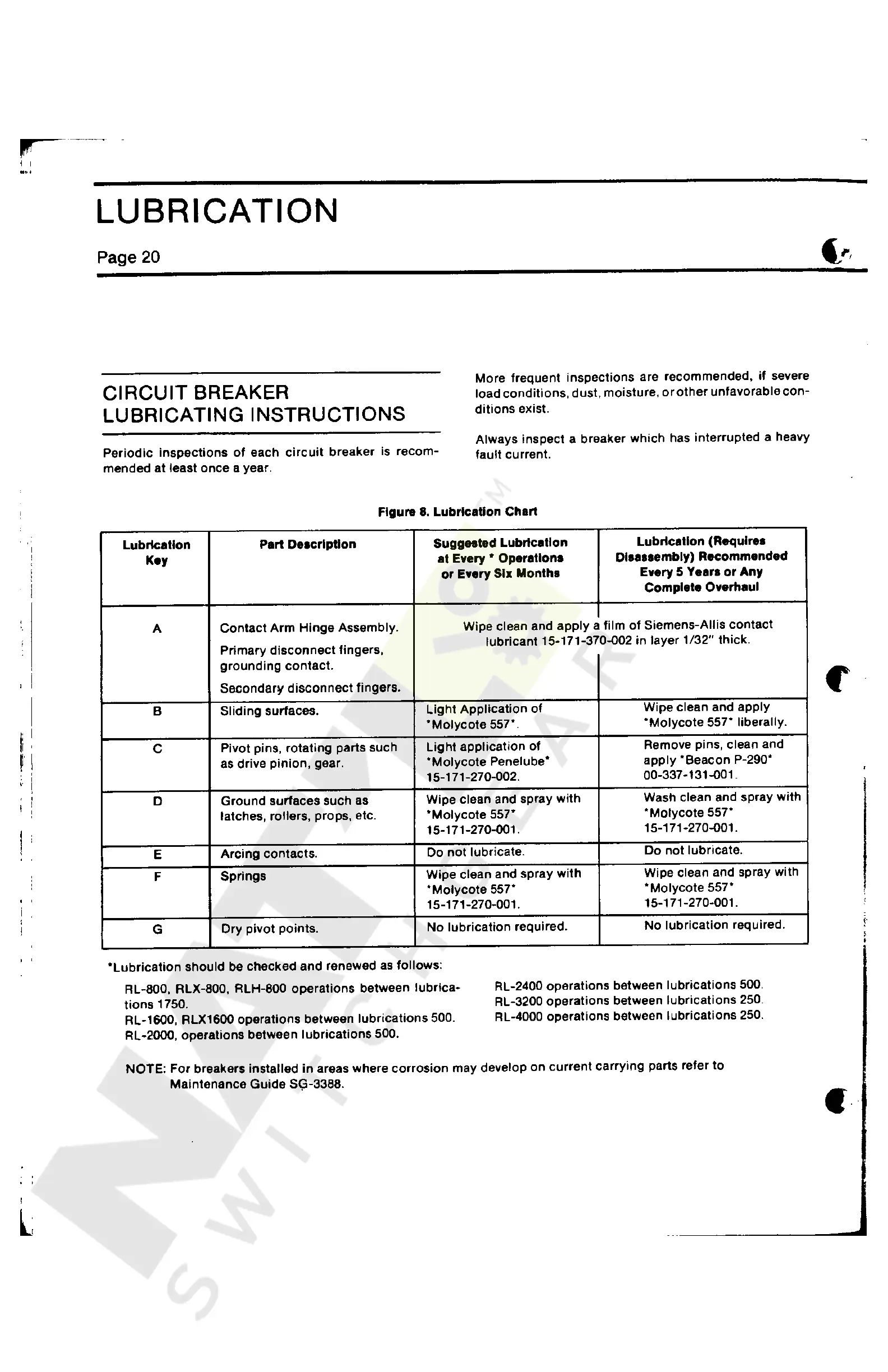

Figure 8. Lubrication

Chart

Lubrication

Part De1crlptlon

Suggested Lubrication

Lubrication (Requires

Key

at Every • Operations

Disassembly)

Recommended

or Every Six Months

Every 5 Years

or

Any

Complete

Overhaul

A

Contact Arm Hinge Assembly.

Wipe clean and apply a film

of

Siemens-Allis contact

Primary disconnect fingers,

lubricant 15-171-370-002 in layer 1/32" thick.

grounding

contact.

Secondary

disconnect

fingers.

B

Sliding surfaces.

Light Application

of

Wipe clean and apply

·Molycote

557•_

·Molycote

557'

liberally.

C

Pivot pins, rotating parts such

Light

application

of

Remove pins, clean and

as drive pinion, gear.

·Molycote

Penelube·

apply • Beacon P-290•

15-171-270-002.

00-337-131-001.

D

Ground surfaces such

as

Wipe clean and spray with

Wash clean and spray with

latches, rollers, props, etc.

·Molycote

557•

• Molycote 557•

15-171-270-001.

15-171-270-001.

E

Arcing contacts.

Do not lubricate.

Do not lubricate.

F

Springs

Wipe clean and spray with

Wipe clean and spray with

• Molycote 557•

·Molycote

557•

15-171-270-001.

15-171-270-001.

G

Ory pivot points.

No

lubrication required.

No

lubrication required.

·Lubrication

should be checked

and

renewed

as

follows:

RL-800, RLX-800, RLH-800 operations between lubrica-

tions

1750.

RL-1600, RLX1600 operations between lubrications 500.

RL-2000, operations between lubrications 500.

RL-2400 operations between lubrications

500.

RL-3200 operations between lubrications

250.

RL-4000 operations between lubrications

250.

NOTE:

For

breakers installed

in

areas where corrosion may develop on

current

carrying parts refer

to

Maintenance Guide S~-3388.

{I",

!

•

Courtesy of NationalSwitchgear.com

Loading...

Loading...