Mechanical Data

2.1 Definitions

Note

When engineering motors, types of construction IM V3, IMV19 and IM V36, the permissible

axial forces (force due to the weight of the drive-out elements) and especially the necessary

degree of protection must be carefully observed.

Threaded inserts are included in the retaining holes for the following types of construction:

IM B14, IM V18 and IM V19

,0 %

,0%

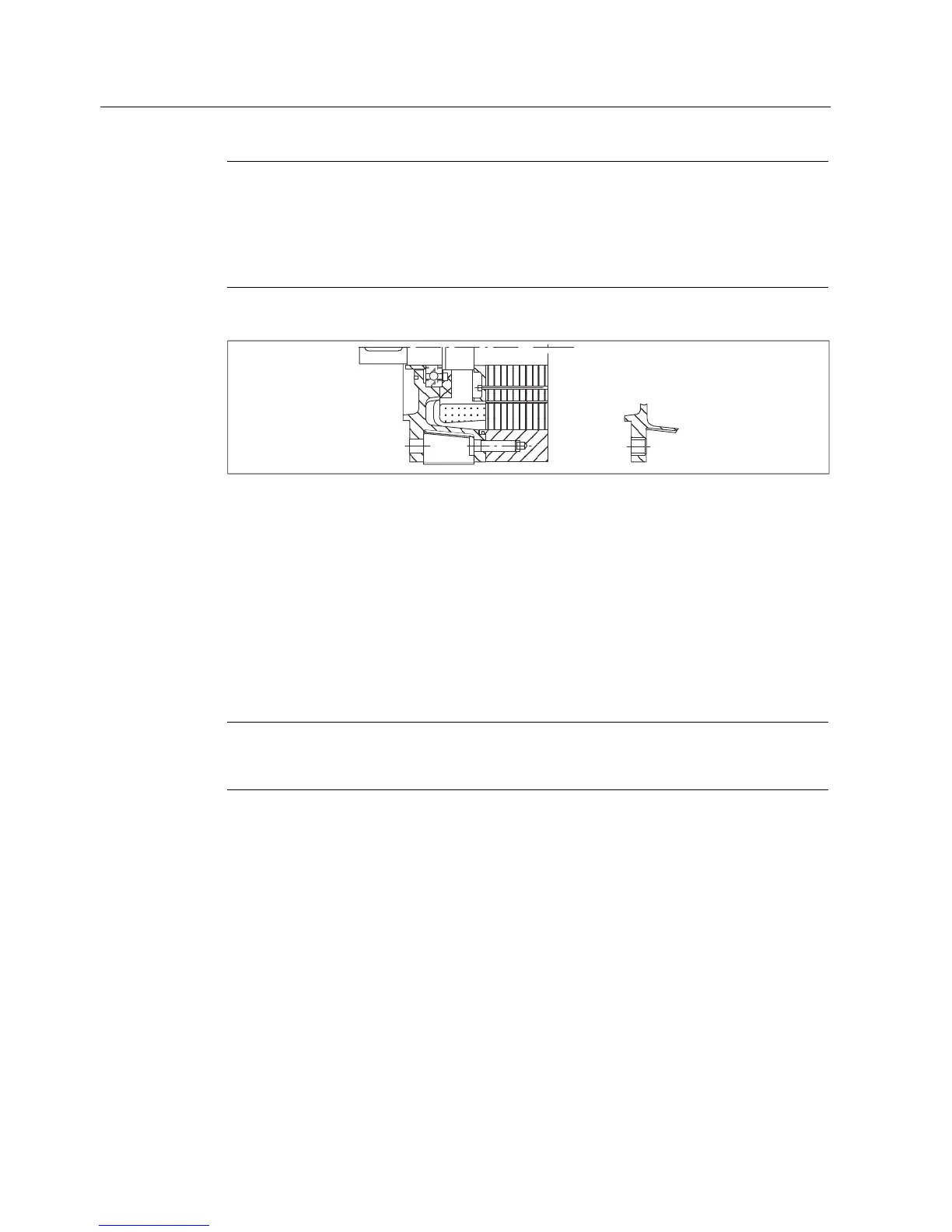

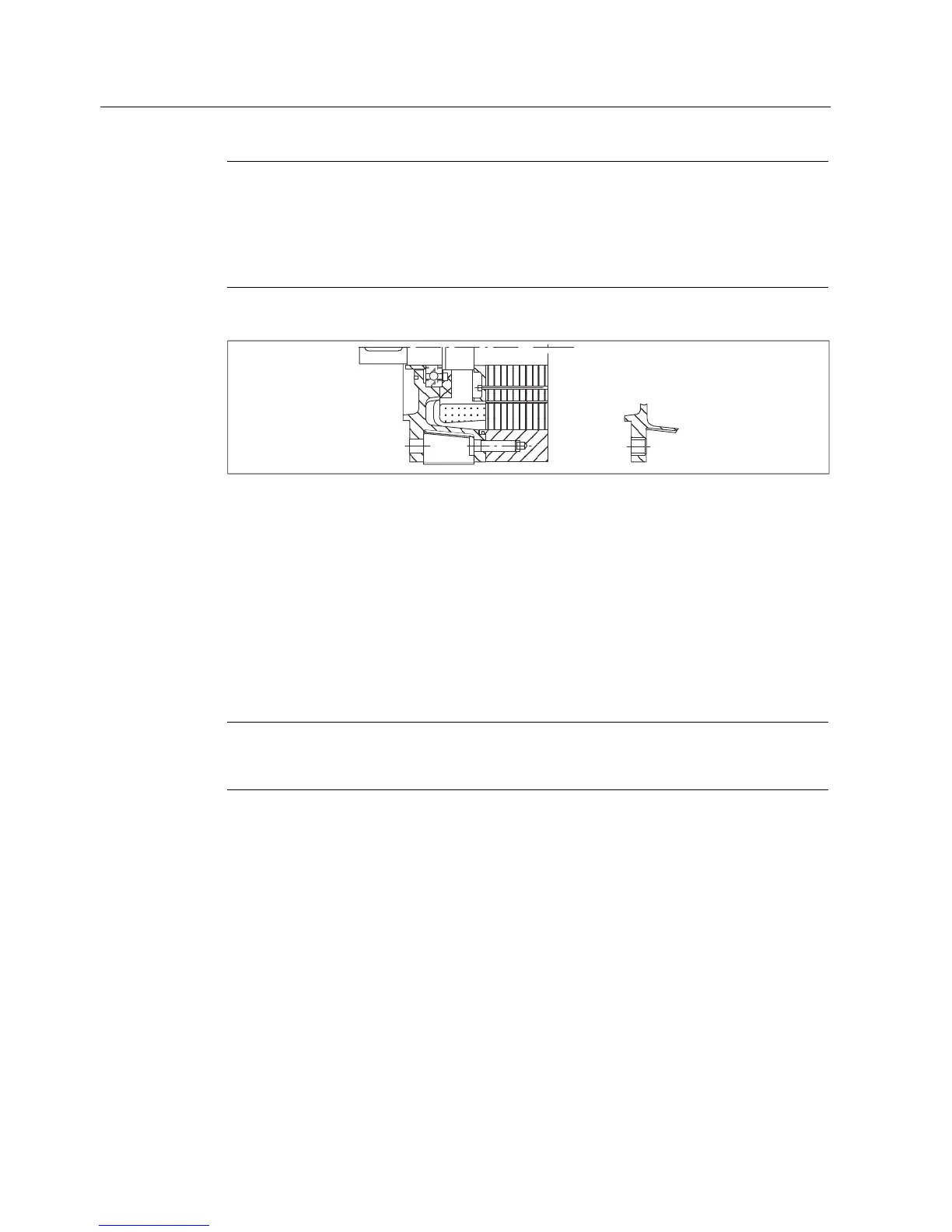

Figure 2-2 Type of construction IM B5/IM B14 (with metric threaded insert)

Surface temperature

The surfaces of synchronous motors can have temperatures > 100 °C. When required,

protective measures must be provided to prevent coming into contact with the motors.

Storage

The bearings are sealed at both sides and are permanently lubricated. The bearings are

designed for a minimum ambient temperature in operation of -15 °C.

Note

We recommend that the bearings are replaced after approx. 20 000 operating hours,

however, at the latest after 5 years.

Shaft end

The cylindrical shaft ends according to DIN 748. IEC 60072 can either be ordered with or

without keyway. The force-locked shaft-hub couplings are preferred for fast acceleration and

reversing operation of the drives.

Mechanical turning

It is not possible to mechanically move the axis at the non-drive end of the motor. If the drive

is to be manually rotated, then this should be done at the most accessible position (e.g. ball

screw spindle).

General Section for Synchronous Motors

2-2 Configuration Manual, (PJAL), 11.2005 Edition, 6SN1 197-0AD07-0BP4

Loading...

Loading...