Mechanical Data

2.1 Definitions

Operation under vibrational conditions, shock stressing

In order to ensure perfect functioning and a long bearing lifetime, the vibration values

specified according to ISO 10816 should not be exceeded.

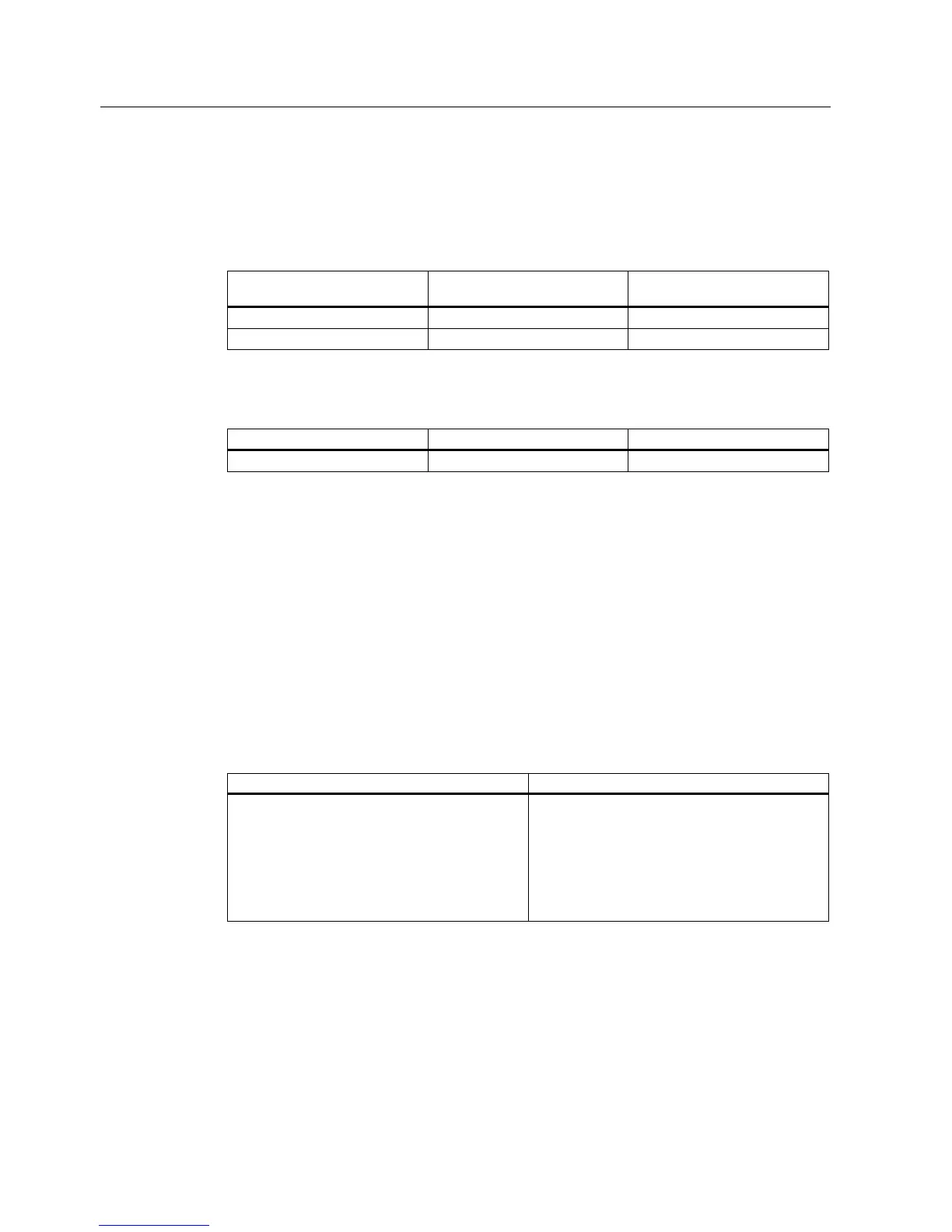

Table 2-2 Vibration values

Vibrational velocity V

rms

(mm/s)

acc. to DIN ISO 10816

Frequency f (Hz) Acceleration a (m∕s

2

)

4.5 10 0.4

4.5 250 10

Deviating from the specified standard, motors 1FK702 to 1FK710 and 1FT602 to

1FT610 may be operated with higher loads but taking into account that the lifetime will be

reduced. In this case, only operation outside the natural frequency is permissible.

Peak acceleration Axial 20 m/s

2

Radial 50 m/s

2

Shock duration 3 ms 3 ms

Balancing (acc. to DIN ISO 8821) for motors with keyway

Motors with key in the shaft are half-key balanced. A mass equalization for the protruding

half key must be taken into account for the drive-out elements.

Cantilever force/axial force stressing

Refer to the appropriate motor Planning Guide for a description and diagrams.

Paint

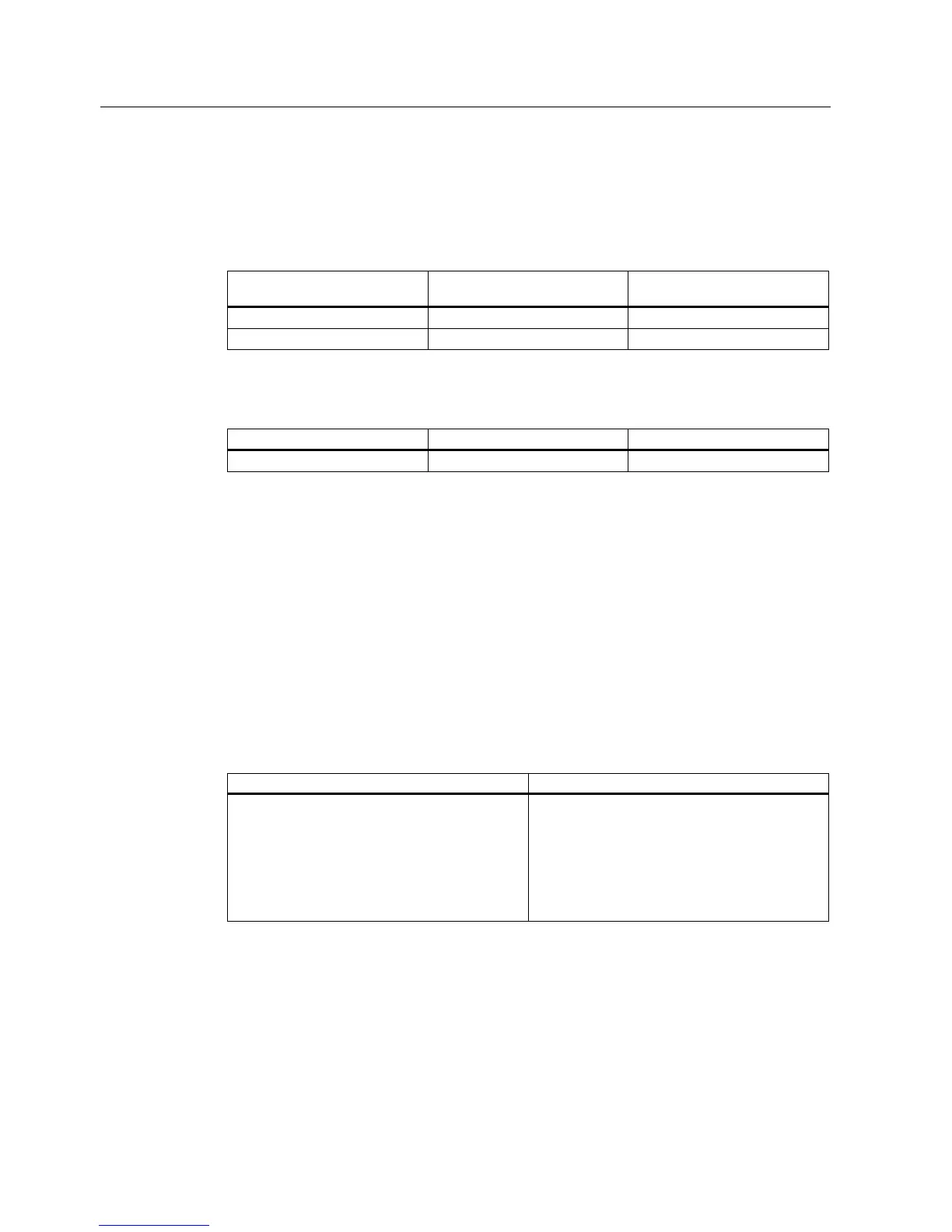

Table 2-3 Paint finish for 1FT☐ and 1FK☐

1FT☐ 1FK☐

Anthracite (similar to RAL 7016)

Two component epoxy resin paint;

An additional paint finish is not required when the

motors are used in sub-tropical regions.

Without paint finish

Option: with paint finish (anthracite)

The motors must be ordered with a special paint

finish if they are to be used in sub-tropical regions

and if they are to be transported by sea. This

paint finish prevents the stator core from

corroding.

Degree of protection (acc. to EN 60034-5)

The motors are available in various degrees of protection. Refer to Table "Selecting the

motor degree of protection"

For motors with forced ventilation, the separately-driven fan is only available in degree of

protection IP 54. All of the seals are manufactured from fluoride rubber (FPM).

General Section for Synchronous Motors

2-4 Configuration Manual, (PJAL), 11.2005 Edition, 6SN1 197-0AD07-0BP4

Loading...

Loading...