Mechanical Data

2.2 Selecting the motor degree of protection

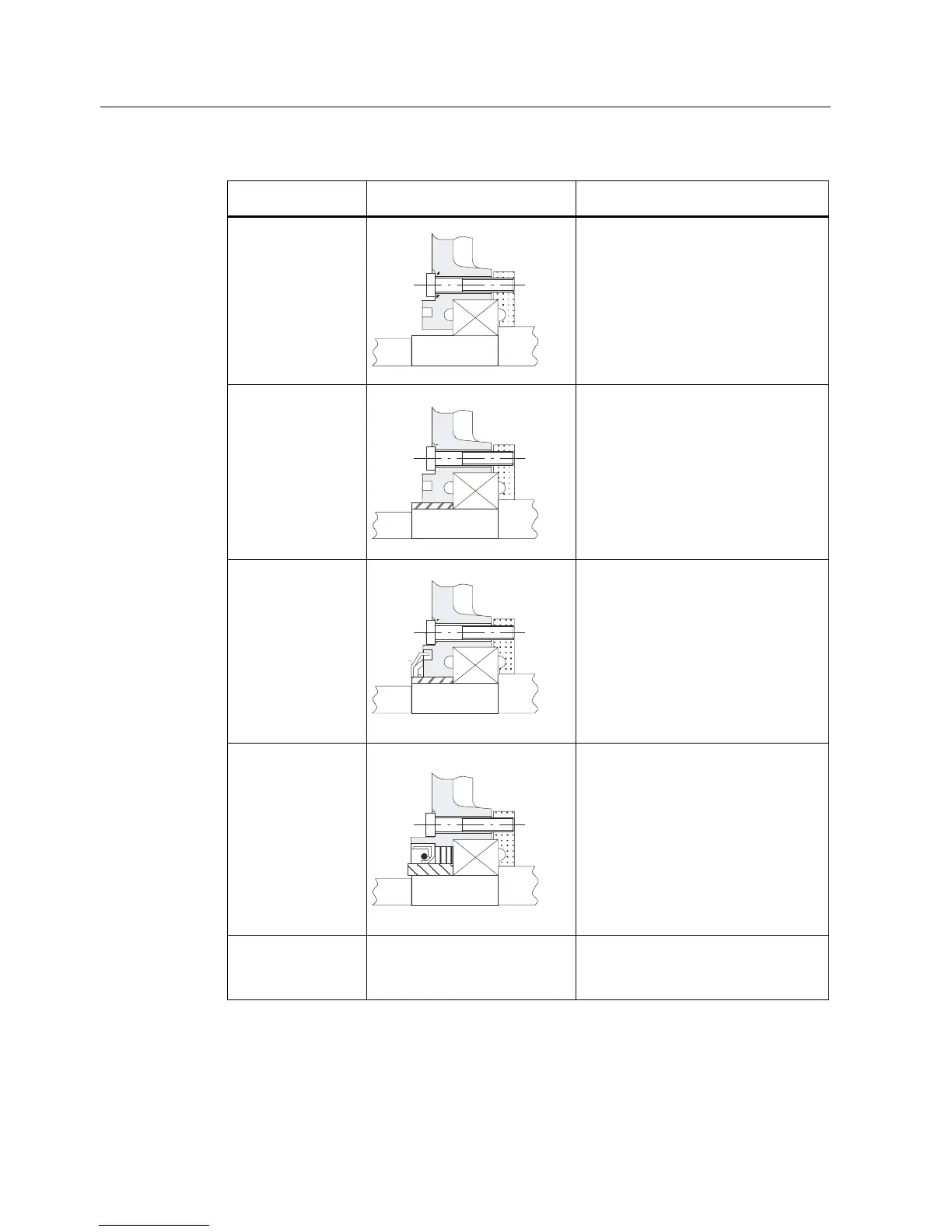

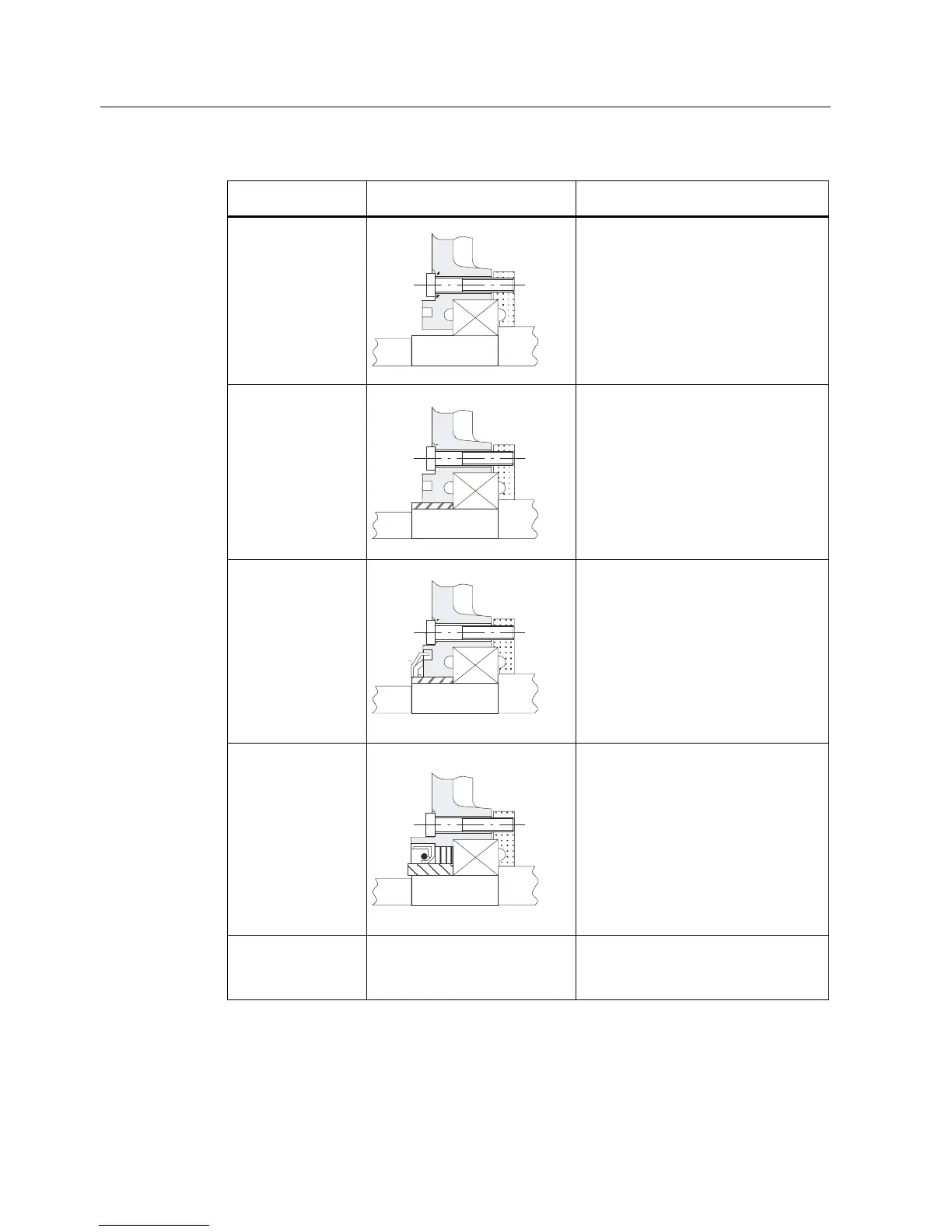

Table 2-5 Overview, motor shaft sealing

Degree of protection

EN 60034-5

Shaft sealing using Applications

IP64 (for 1FK) Without simple labyrinth seal

It is not permissible that there is any

the flange.

Note:

For IP 64 degree of protection it is not

permissible that liquid collects in the

flange.

Shaft outlet is not dust tight

IP64 (for 1FT) Labyrinth seal

It is not permissible that there is any

the flange.

Note:

For IP 64 degree of protection it is not

permissible that liquid collects in the

flange.

Shaft outlet is not dust tight

IP65 (only for 1FT6

)

Gamma ring

Shaft outlet seal to protect against spray

water and cooling-lubricating medium. It

is permissible that the Gamma ring runs

For IP65 degree of protection it is not

permissible that liquid collects in the

flange.

IP65

1)

for 1FK☐

IP67

2)

(for 1FT☐)

Radial shaft seal DIN 3760

For gearbox mounting (for gearboxes

which are not sealed) to seal against oil.

The sealing lip must be adequately

in order to guarantee reliable function.

Lifetime 5000 h - 10000 h (nominal

value)

If a radial shaft sealing ring runs dry, then

functionality and the lifetime.

IP68

2)

(only for 1FT6)

Refer to IP 67; in addition, a

wetting sealing agent is used at

the mechanical interfaces to the

frame.

Refer to IP 67

moisture in the area around the shaft and

moisture in the area around the shaft and

dry. Lifetime 20 000 h (nominal value).

cooled and lubricated by the gearbox oil

this has a negative impact on the

1)

For 1FK7, DE flange, IP67

2)

For 1FT6, sealing air connection in the cover at the non-drive end (this can be used as an additional sealing measure when the motors are

operated in extremely moisture/humid environments)

General Section for Synchronous Motors

2-6 Configuration Manual, (PJAL), 11.2005 Edition, 6SN1 197-0AD07-0BP4

Loading...

Loading...