808D ADVANCED Page 83 Programming and Operating — Turning

Additional

Information

Part 2

s

SEQUENCE

M/H

Function

Sub

program

Frequently used machining sequences, e.g. certain contour shapes, are

stored in subprograms. These subprograms are called at the appropriate

locations in the main program and then executed.

The structure of a subprogram is identical to that of the main program, but

a subprogram contains M17 - end of program in the last block of the pro-

gram sequence. This means a return to the program level where the sub-

program was called.

The subprogram should be given a unique name enabling it to be selected

from several subprograms. When you create the program, the program

name may be freely selected.

However, the following rule should be observed:

The name can contain letters, numbers and underscores and should be

between 2 and 8 characters long.

Example: LRAHMEN7

The M function initiates switching operations, such as "Coolant ON/OFF".

Various M functions have already been assigned a fixed functionality by

the CNC manufacturer. The M functions not yet assigned are reserved for

free use of the machine tool manufacturer.

With H functions, the meaning of the values of a specific H function is

defined by the machine tool manufacturer.

M codes and H functions created by the OEM should be backed up by the

machine tool manufacturer.

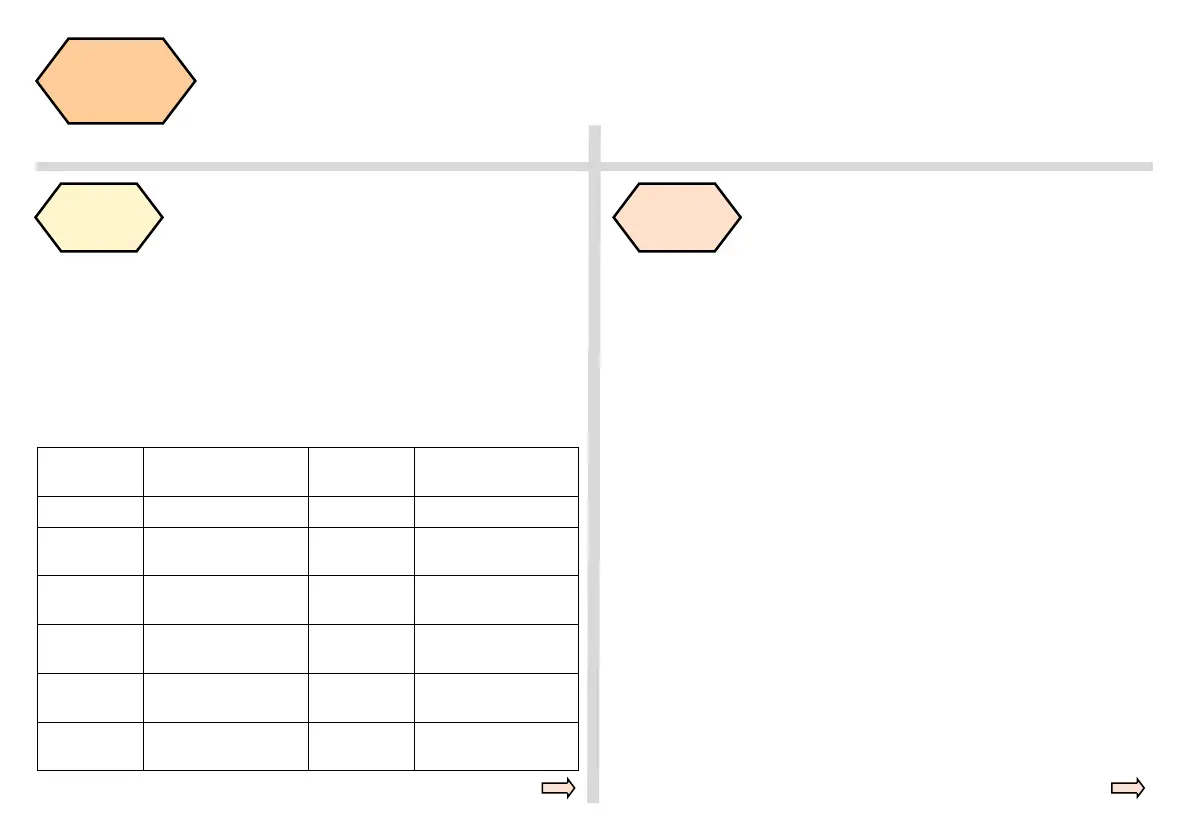

Specified M

Function

Explanation Specified M

function

Explanation

M0 Stop program M7 / M8 Coolant on

M1 Stop program with

conditions

M9 Coolant off

M2 End program M10 / M11 Chuck close / re-

lease

M30 End program and

back to the beginning

M20 / M21 Tailstock release /

close

M17 End subprogram M40 Select gear stage

automatically

M3 / M4 / M5 Spindle CW/CCW/

Stop

M41~M45 Change spindle gear

Loading...

Loading...