Programming and Operating — Turning Page 82 808D ADVANCED

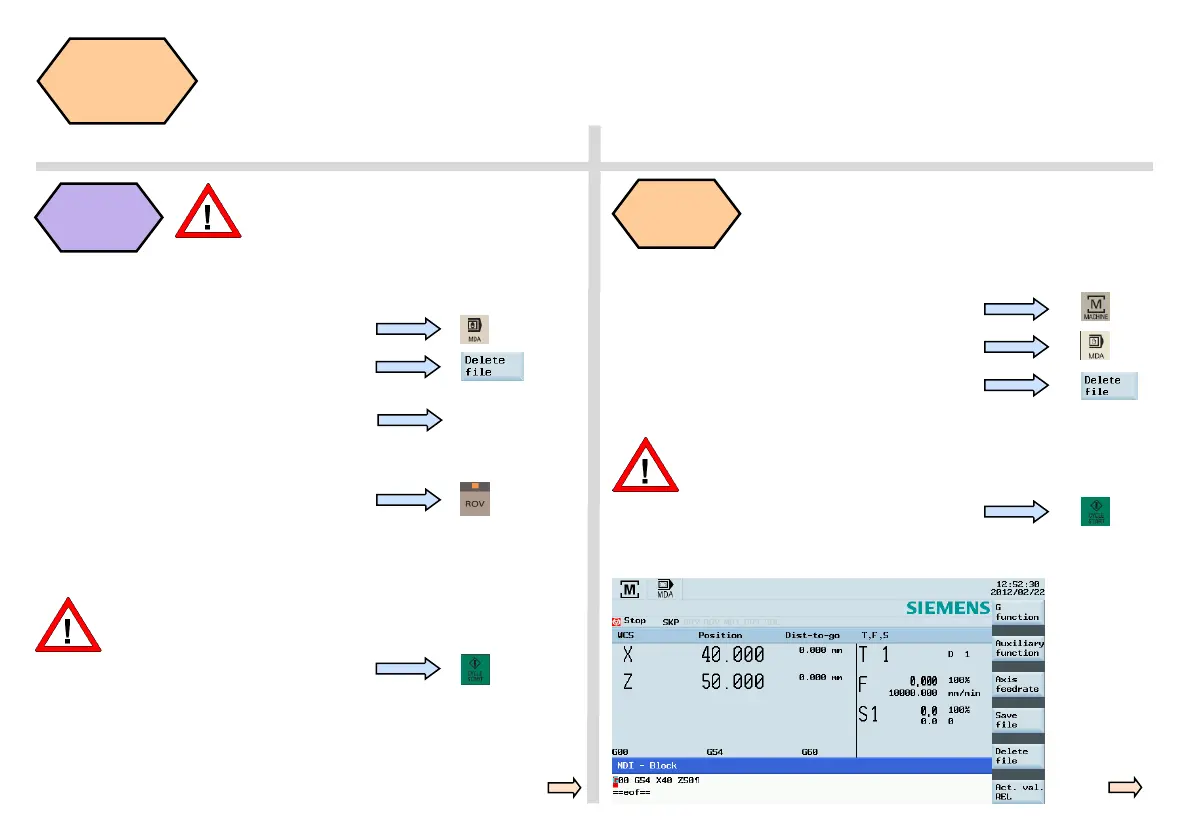

Workpiece

Setup

s

SEQUENCE

Enter the test program recommended on

the right.

The tool setup and workpiece setup

must have been performed correctly so

that it can be tested as follows!

Press the “MDA” key on the MCP.

Press the “Delete file” SK on the PPU.

Press “CYCLE START” on the MCP.

G54 (select offset

panel as re-

quired)

T1 D1

G00 X0 Z5

Press the “ROV” key to ensure the “ROV”

function is active (the function is activated

when the light on the key is on).

Make sure the feedrate override on the MCP is at 0%!

Increase the feedrate override gradually to avoid accidents caused by an

axis moving too fast and observe whether the axis moves to the set

position.

Note: The ROV function activates the feedrate override switch under the

G00 function.

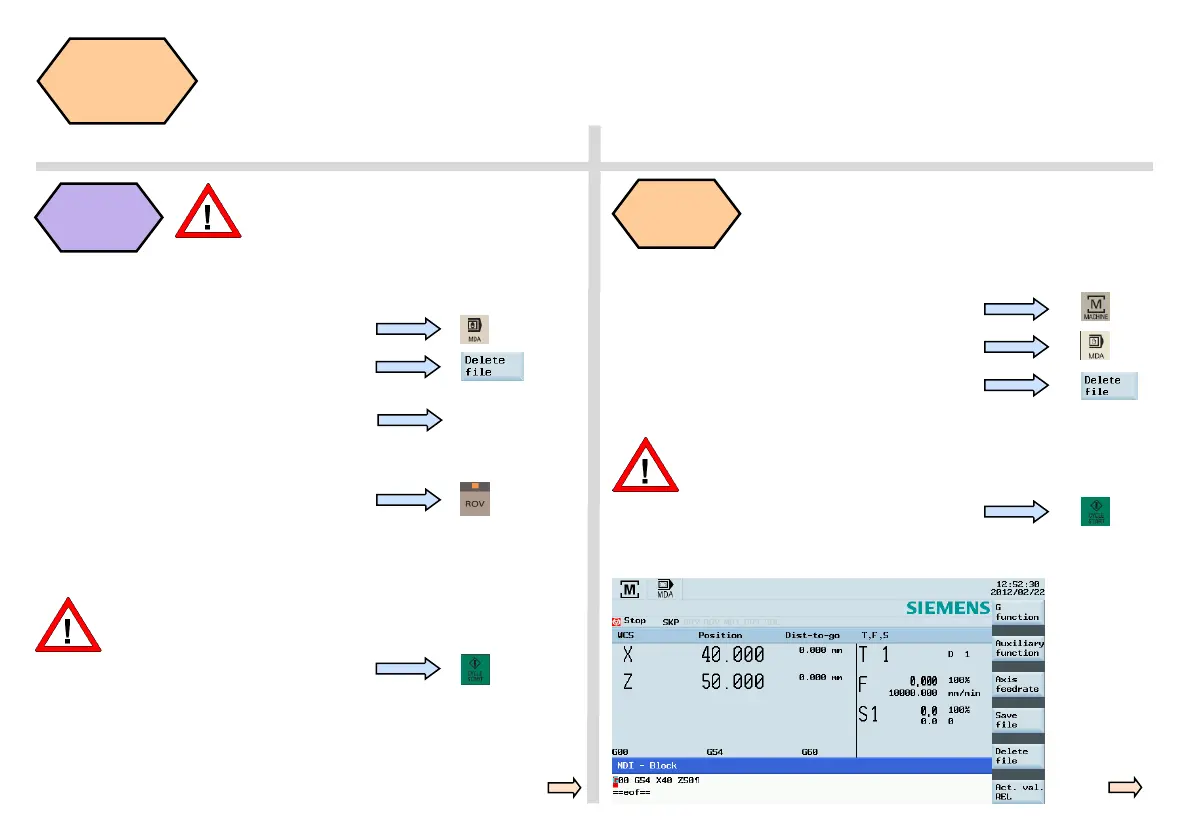

Test tool

offset

results

In order to ensure the machine safety and correctness, the results of the

tool offset should be tested appropriately.

MDA

Use MDA to move the axis to a fixed position.

Press the “MDA” key on the PPU.

Enter correct NC code to move the axis to the required position...

Press the “Delete file” SK on the PPU.

Press “CYCLE START” on the MCP to execute the

MDA program.

Make sure the feedrate override on the MCP is at 0%!

Turn the feedrate override on the MCP gradually to the required value.

Press the “Machine” key on the PPU.

In MDA mode, you can enter and execute single and

multiple lines of NC codes.

Loading...

Loading...