808D ADVANCED Page 81 Programming and Operating — Turning

Workpiece

Setup

s

SEQUENCE

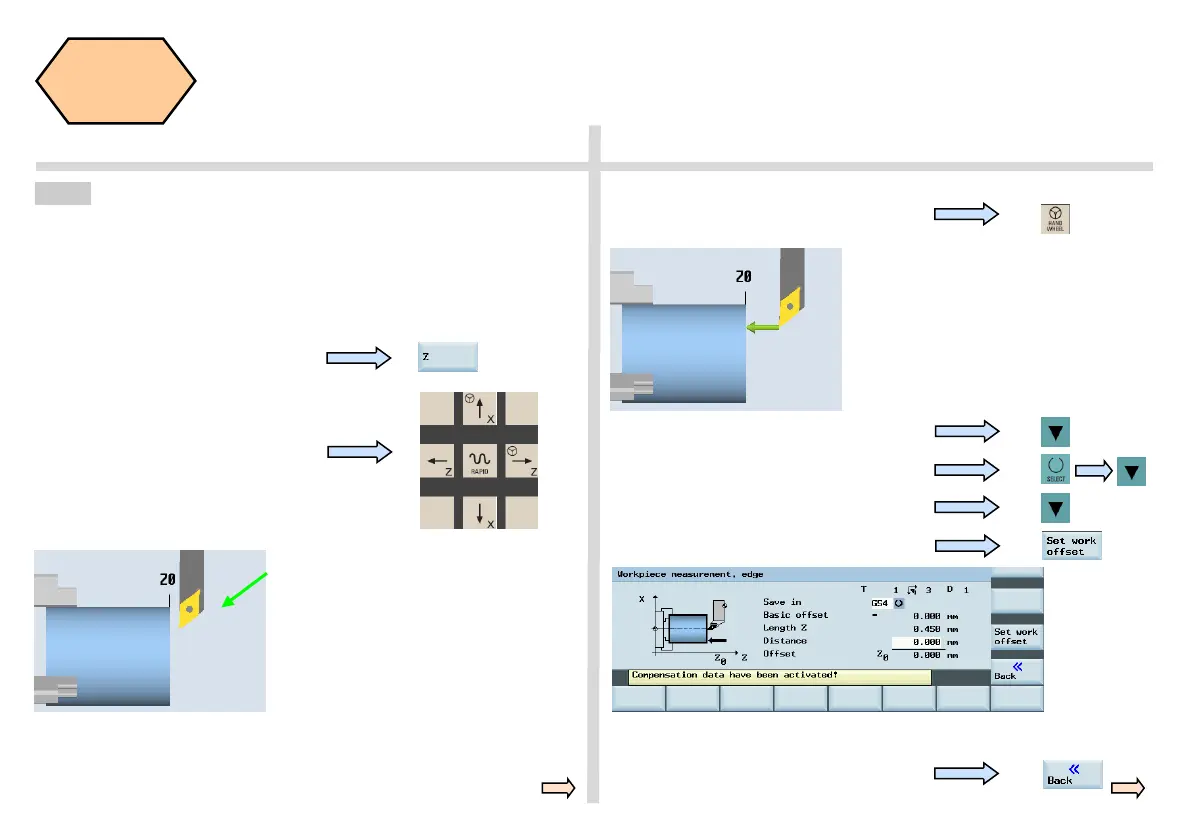

Step 2

Press the SK on the PPU to select

the required setting axis.

Press the axis traverse keys to

move the tool to the required set-

ting position in the Z axis.

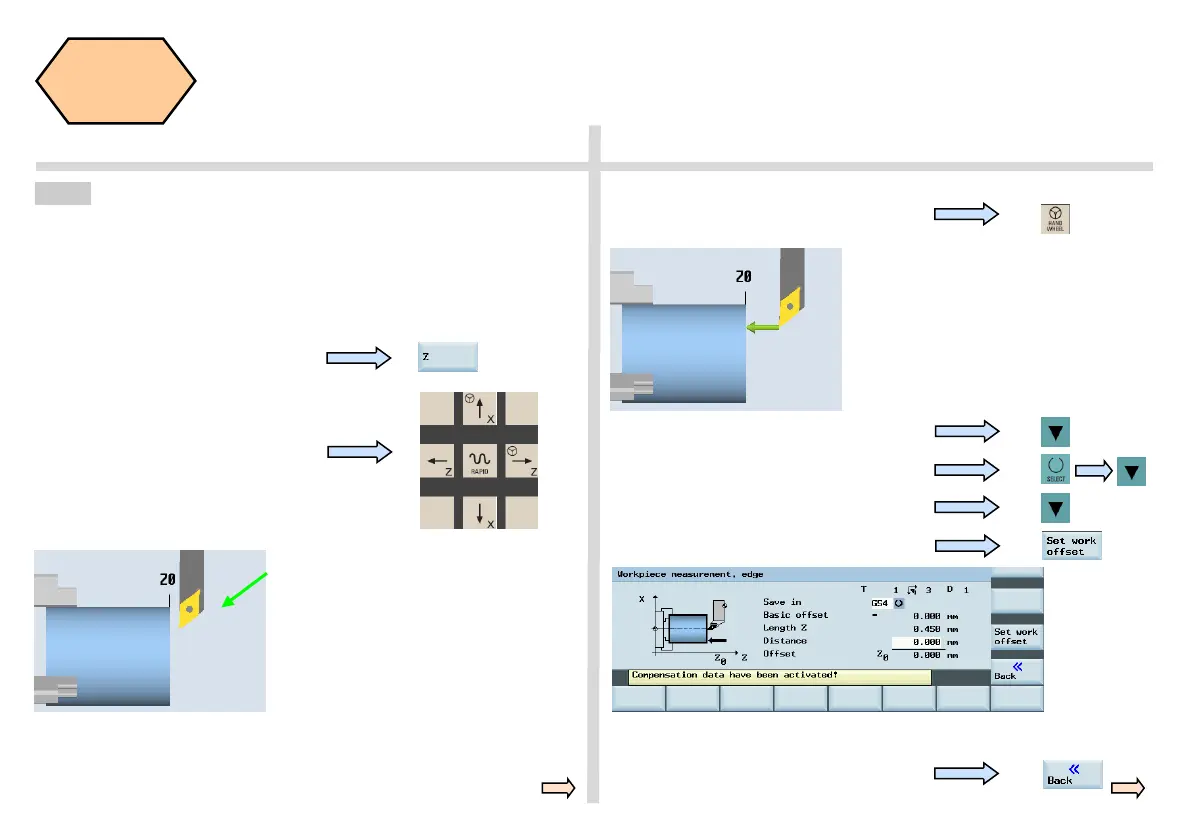

Press the “Handwheel” key on the MCP to

move the tool to the Z0 position on the

workpiece.

Enter tool number “1” in “T”.

Set “Distance” as “0”

Set “Save in” as “G54” (or other offset).

Press the “Set work offset” SK on the PPU.

Using a tool that has a measured “Tool length”, move the tool to a known

position on the workpiece. Using either JOG or Handwheel, scratch an

edge and then calculate the zero point of the workpiece.

The process of setting the zero point (“Z0”) is described below.

Repeat the operations to set the “X” zero point.

Press the “Back” SK on the PPU after

measuring.

Loading...

Loading...