808D ADVANCED Page 95 Programming and Operating — Turning

Sample

Programs

s

Tool information:

T1 Turning tool D0.8 T5 Grooving tool D0.2

Tool tip width 3

T2 Turning tool D0.8 T6 Drilling tool D10

T3 Grooving tool D0.2

Tool tip width 2 T7 Drilling tool D10

T4 Turning tool D0.8 T8 Tap D12

Turning

program 3

Part of the cycles in the program are

taken as examples in Section 5, “Create

Part Program Part 2”!

N10 G00 G90 G95 G40 G71

N20 LIMS=4500

; ==Start contour turning roughing==

N30 T1 D1 ;ROUGH TURN

N40 G96 S250 M03 M08

N50 G00 X52.0 Z0.1

N60 G01 X-2.0 F0.35

N70 G00 X52.0 Z2.0

N80 CYCLE95( "SUB_PART_3", 2.5,

0.2, 0.1, 0.15, 0.35, 0.2, 0.15, 9, , , )

N90 G00 G40 X500.0 Z500.0

N100 M01

; ==Start contour turning finishing ==

N110 T2 D1 ;FINISH TURN

N120 G96 S350 M03 M08

N130 G00 X22.0 Z0.0

N140 G01 X-2.0 F0.15

N150 G00 Z2.0

N160 X52.0

N170 CYCLE95( "SUB_PART_3", , ,

, , , , 0.15, 5, , , )

N180 G00 G40 X500.0 Z500.0

N190 M01

; ========Start grooving=========

N200 T3 D1 ;GROOVE

N210 G96 S200 M03 M08

N220 G00 X55.0 Z0.

N230 CYCLE93( 30, -30.5, 7, 5, 0, 0,

0, 1, 1, , 0, 0.2, 0.1, 2.5, 0.5, 11, )

N240 G00 G40 X500.0 Z500.0

N250 M01

; =========End grooving=========

N10 spindle feedrate in mm/r

N20 set spindle upper limit 4500 r/min

; ==Start contour turning roughing==

N30

N40 constant cutting speed 250 m/min

N50 feedrate is 0.35 mm/r

N60

N70

N80 maximal feed depth 2.5 mm,

vertical axis finishing allowance 0.2 mm,

horizontal axis finishing allowance 0.1

mm, contour finishing allowance 0.15

mm, roughing feedrate 0.35 mm/r,

feedrate 0.2 mm/r with back cut, feed

along negative direction of Z axis to do

complete machining.

N90 G40→cancel tool radius compen-

sation

N100 delay changing tool

; ==Start contour turning finishing ==

N110

N120

N130

N140

N150

N160

N170 finishing feedrate 0.15 mm/min,

feed along negative direction of Z axis to

do complete machining.

N180

N190

; =======Start grooving=========

N200

N210

N220

N230 grooving start point (X30,Y-30.5),

groove width 7mm, depth 5 mm, angle

between contour and Z axis is 0º,

groove bottom finishing allowance 0.2

mm, angle between groove middle both

sides and X axis is 0º, tooth face finish-

ing allowance 0.1 mm, feed depth 2.5

mm, delay 0.5 s at base of groove, de-

fine reverse angle by entering side

length(CHR method).

N240

N250

; =========End grooving======

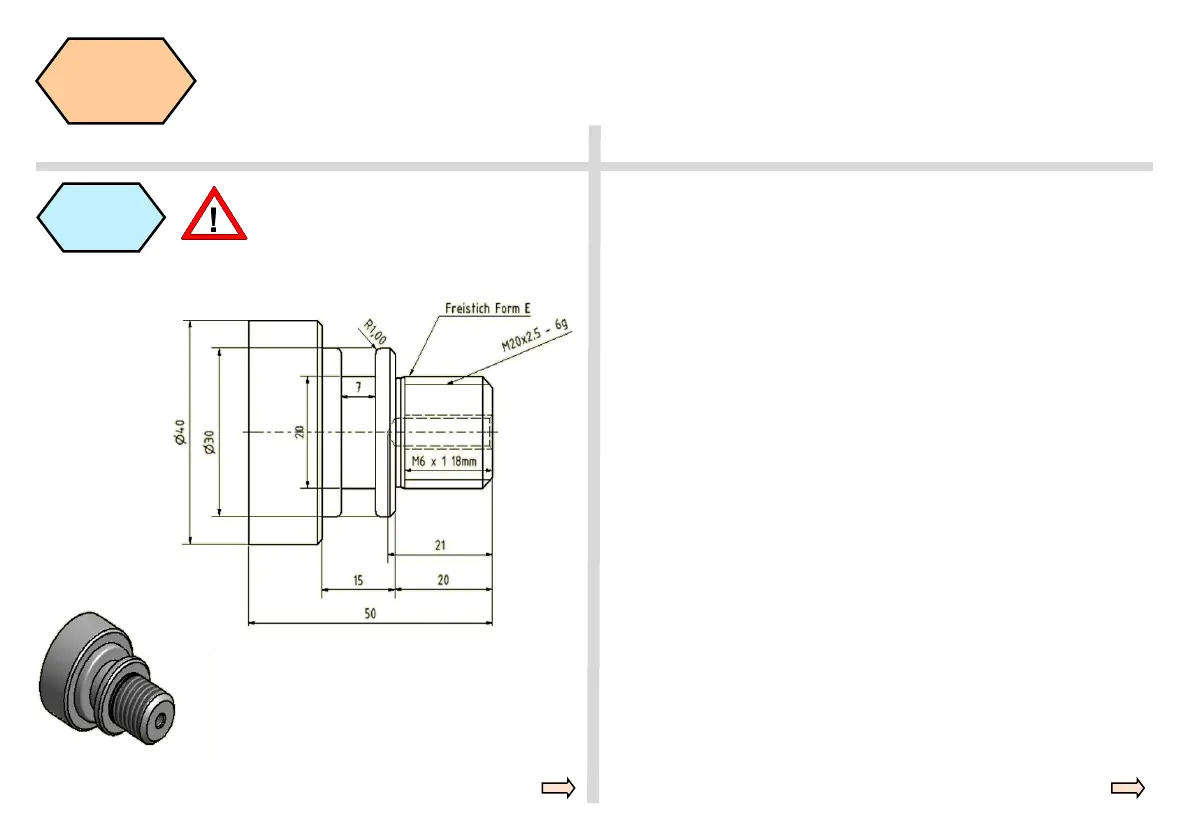

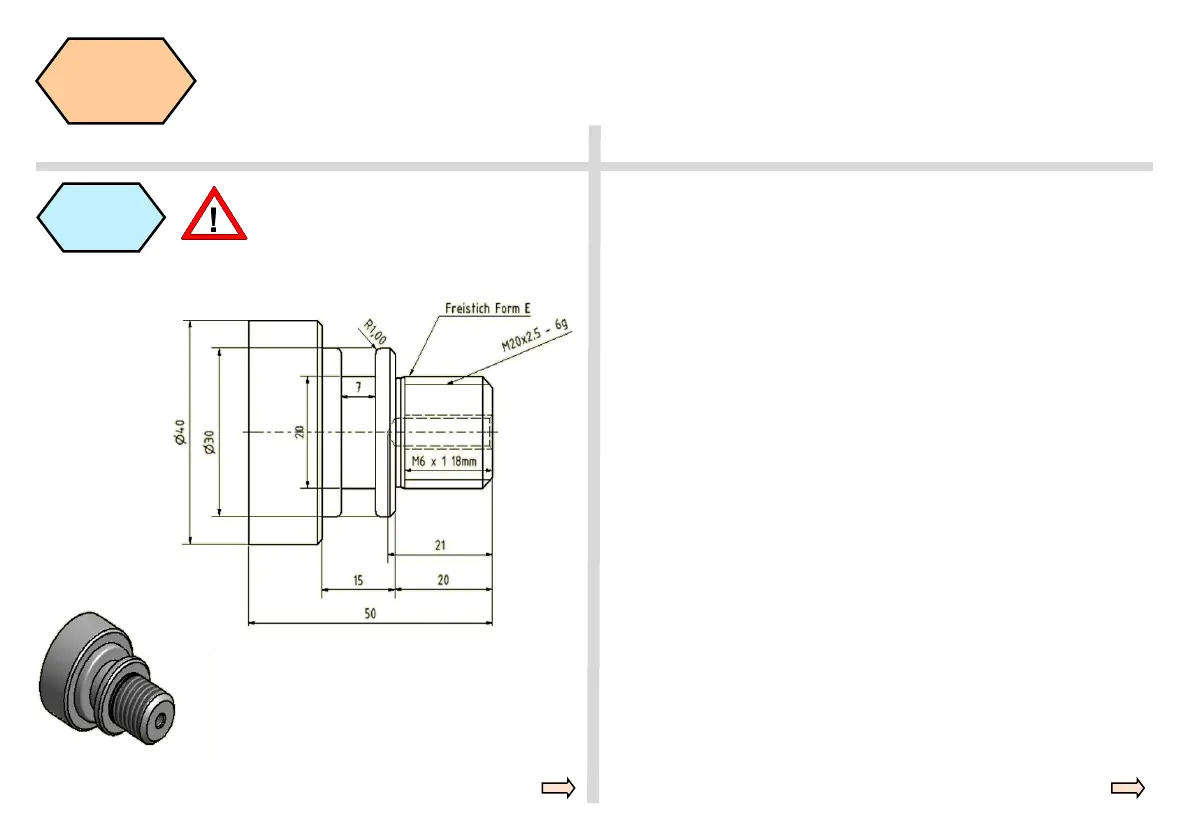

DRAWING

Machining Process

Loading...

Loading...