Operating and Programming — Milling Page 18 808D

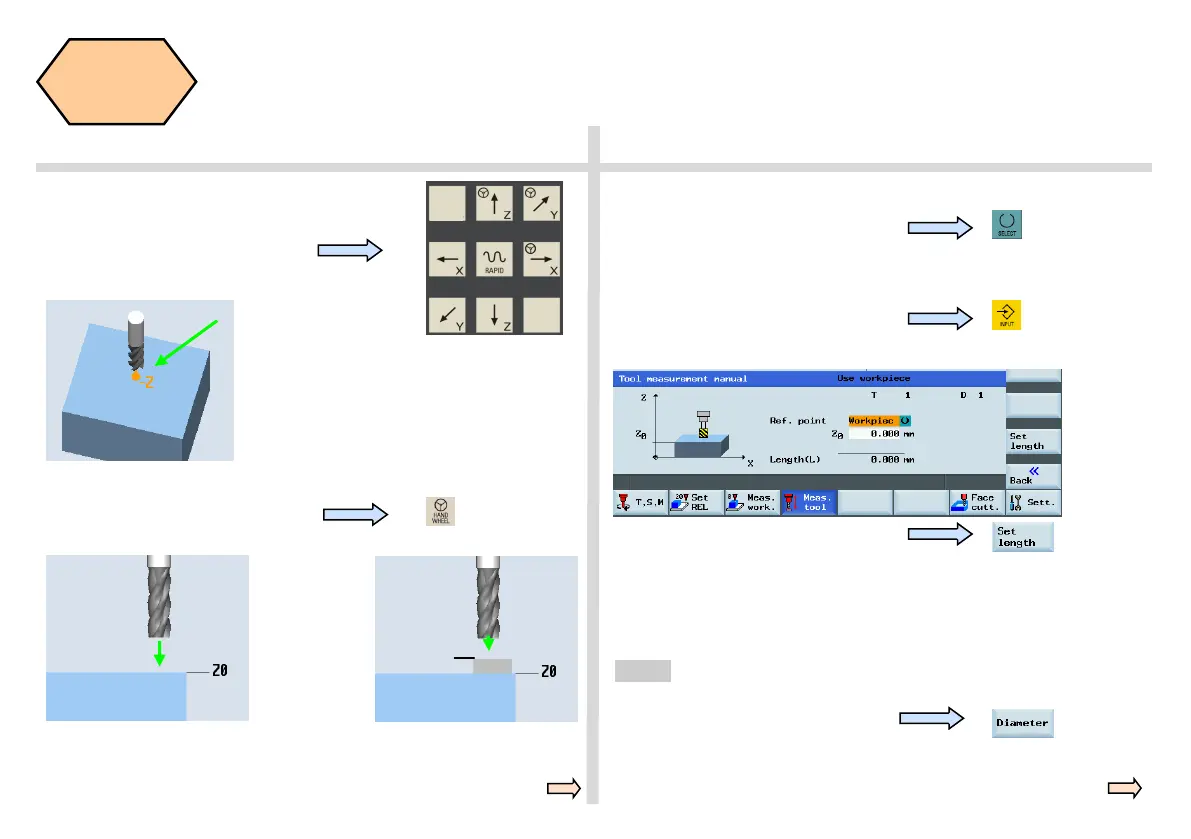

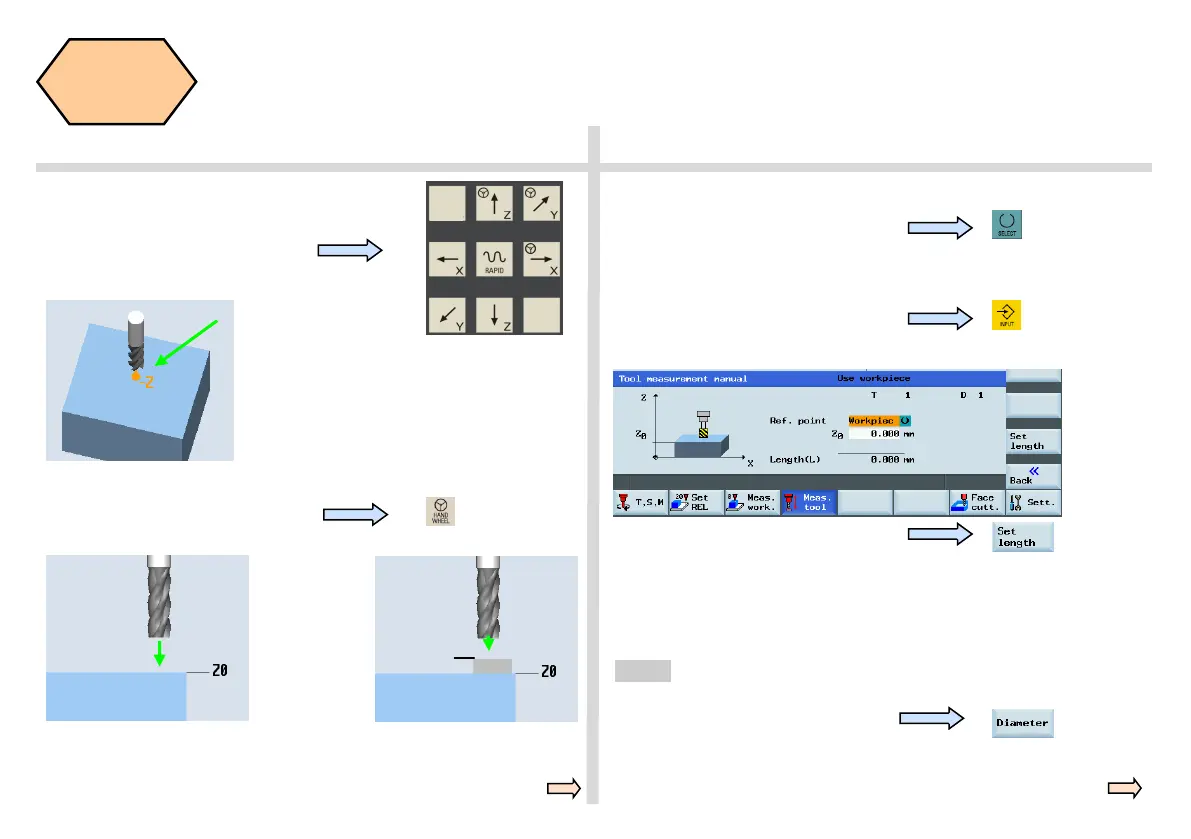

Tool Setup

s

Press the “Set length” SK on the PPU

Enter “0” for “Z0”

(If the setting block is used, then the

value would be thickness a)

Press the “Handwheel” key on the

MPC and position the tool at location

Z0 or a of the workpiece.

or

Move directly to zero point

Use a setting block.

a

Press the “Diameter” SK on the PPU

Step2

Measure diameter

Press the axis keys on the MCP to

move the tool to the set position

above the workpiece.

The measured tool length is now shown in “Length (L)”. This value is

also saved in the length value column of the corresponding tool list at the

same time.

Note: The following text describes the

required settings in the workpiece coordi-

nate system

“X / Y / Z” zero points as:“X0” / “Y0” / “Z0”

Use “SELECT” key to set the refer-

ence point as “workpiece” (In real

measurement, the reference point

can be set as either “workpiece” or

“ fixed point” if required.

SEQUENCE

Loading...

Loading...