Operating and Programming — Milling Page 50 808D

Create Part

Program

Part 2

s

Basic Theory

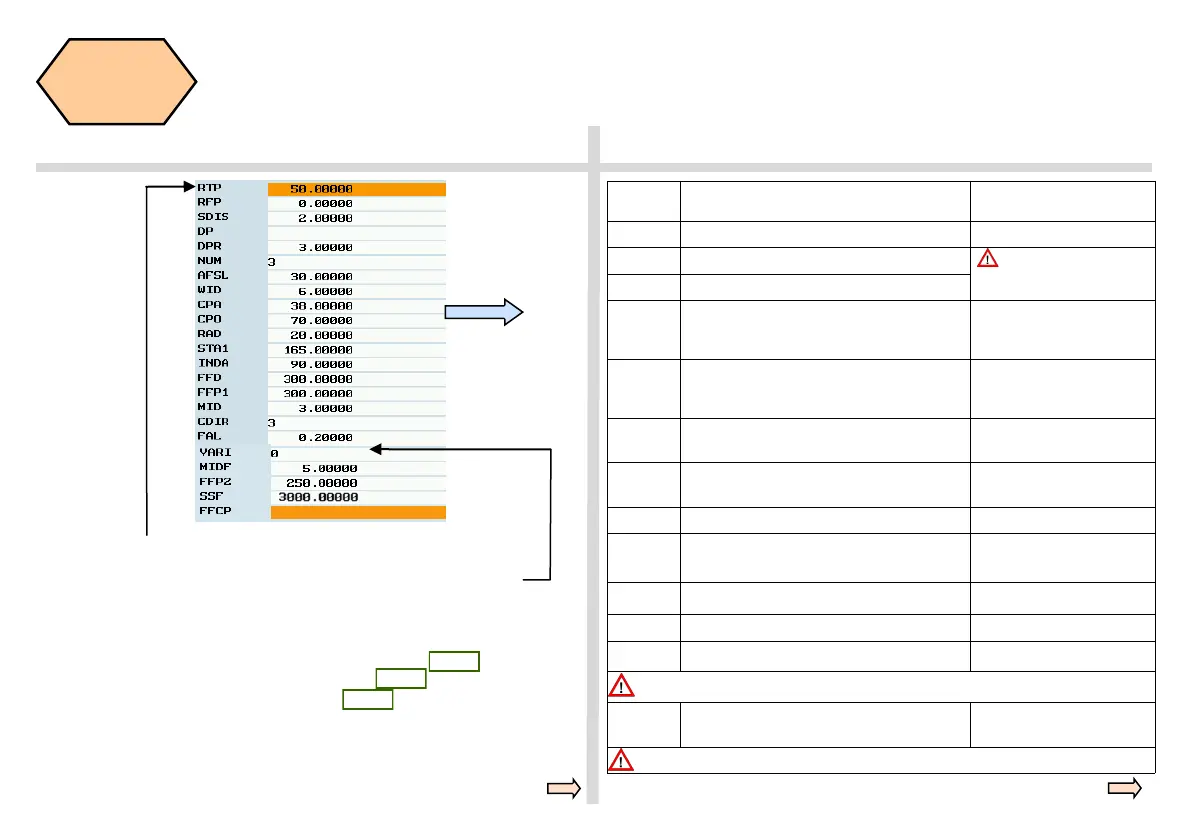

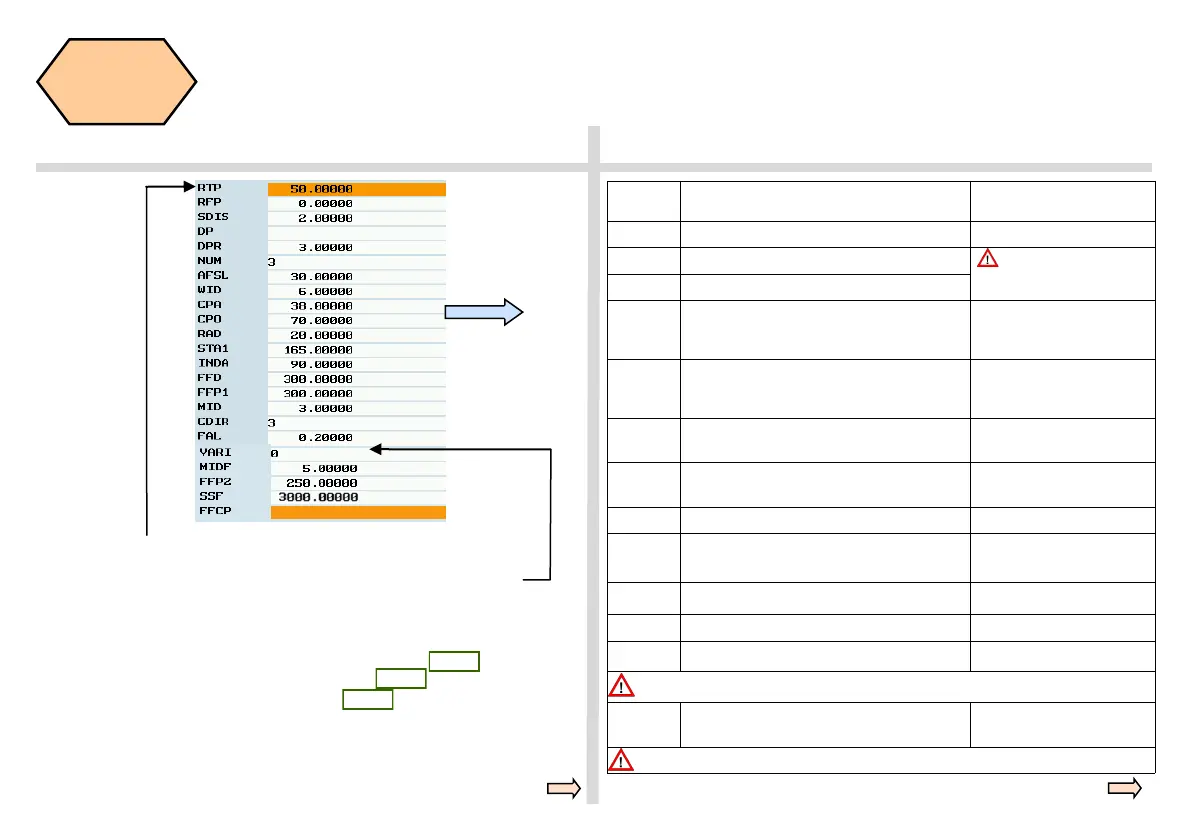

N210 SLOT2( 50.00000, 0.00000, 2.00000, , 3.00000, 3, 30.00000, 6.00000,

38.00000, 70.00000, 20.00000, 165.00000, 90.00000, 300.00000, 300.00000,

3.00000, 3, 0.20000, 2000, 5.00000, 250.00000, 3000.00000, )

Parame-

ters

Meanings Remarks

NUM=3 Three slots on the circle

AFSL=30 Angle slot length is 30º AFSL and WID jointly

decide the shape of the slot in

the plane

WID=6 Slot width is 6 mm

STA1=165

Start angle,angle between the effective work piece

horizontal coordinate in positive direction and the

first circle slot is 165º

INDA=90

Incremental angle, angle between the slots is 90º INDA=0, cycle will calculate

the incremental angle automati-

cally

MID=3 Maximal depth of one feed is 3 mm

MID=0 → complete the cutting

of the slot depth

CDIR=3

Milling direction G3 (in negative direction) Evaluate value 2→use G2 (in

positive direction)

FAL=0.2 Slot side, finishing allowance is 0.2 mm

VARI=0 The type of machining is complete machining

VARI=1→roughing

VARI=2→finishing

MIDF=5 Maximal feed depth of the finishing is 5 mm

FFP2=250 Feed rate of finishing is 250 mm/min

SSF=3000 Spindle speed for finishing is 3000 mm/min

If FFP2/SSF are not specified, then use the feed rate/spindle speed of rotation as default

FFCP= Feed rate at the center position on the circle

path ,unit is mm/min

Before recalling the cycle, you must set the tool radius compensation value.

For descriptions of RTP, RFP, SDIS, DP and DPR, please see page 40

For descriptions of CPA, CPO and RAD, please see page 45

For descriptions of FFD and FFP1, please see page 48

Loading...

Loading...