1 2 MA503 Datum 08.01.2001 Art.Nr. 79539 Z.Nr. 8664078 Änd.Stand 2/01

• Fix cover strip (both ends should slightly

overlap).

• Also fix cover strip’s ends to avoid unin-

tentional peeling.

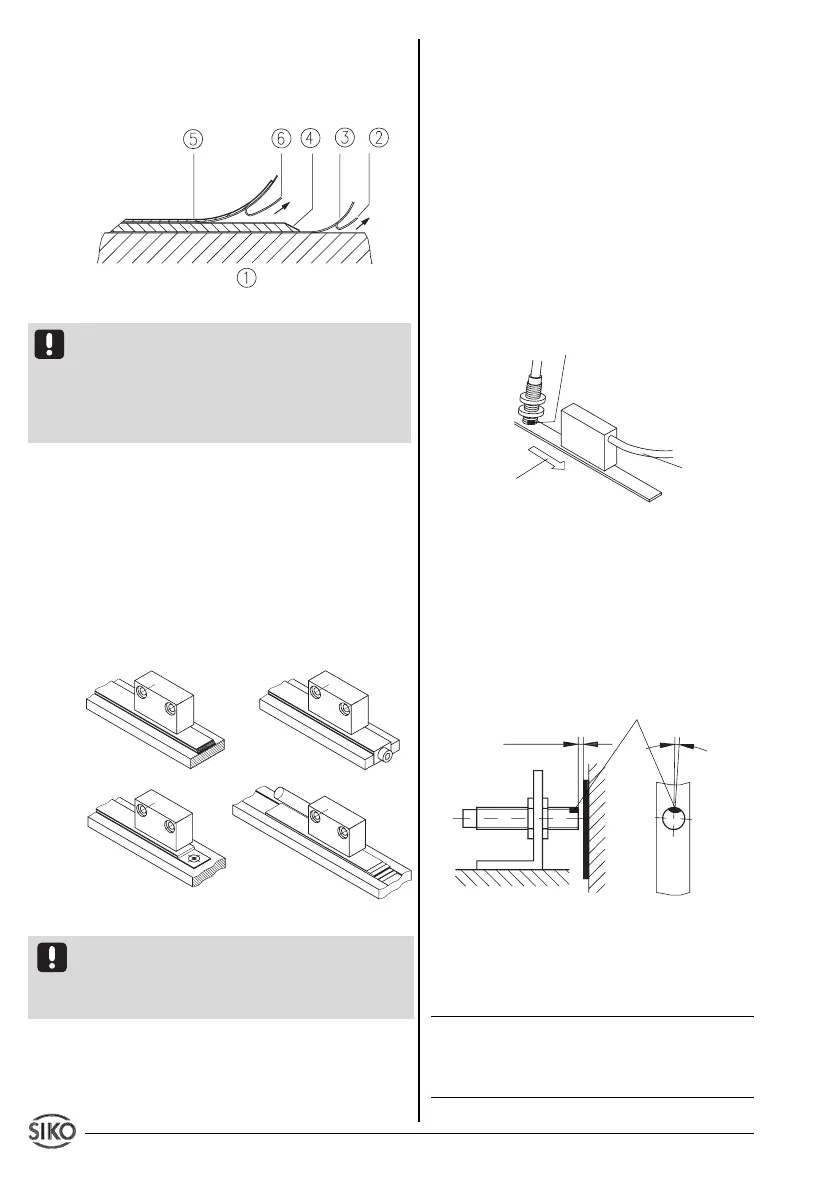

Fig. 1: Mounting of the magnetic strip

Attention ! Do not expose the system to magne-

tic fields. Any direct contact of the magnetic

strip with magnetic fields (eg. adhesive magnets

or other permanent magnets) is to be avoided.

Sensor movements during power loss are not

captured by the follower electronics.

Mounting examples

Mounting with chamfered ends (fig. 2) is not

recommended unless the strip is installed in a

safe and protected place without environmental

influences. In less protected mounting places

the strip may peel. There we recommend moun-

ting accord. to fig. 3 and 4.

Mounting in a groove (fig. 5) best protects the

magnetic strip. The groove should be deep

enough to totally embed the magnetic strip.

Fig. 2 Fig. 3

Fig. 4 Fig. 5

3.2 Mounting the sensor

Attention ! MA503 with socket connector for

sensors Type A, B, F or L to be combined with

magnetic tape MB or MB5. Please also read User

Instructions supplied with magnetic sensors.

Use two M3 screws to fix the magnetic sensor

A via the ø3.5 mm through holes.

Use two M2.5 screws to fix the magnetic sensor

B via the two threaded holes.

Magnetic sensor F can for example be mounted

by using a mounting bracket. For fixing sensor to

mounting bracket use bores and the two nuts

M8x0.5.

Use two M3 screws to fix the magnetic sensor

L via the ø 3.2 mm through holes.

• Cable layout should avoid damages due to

cable strain or other machine parts. If necessary

use a drag chain or protective hose and provide

for strain relief.

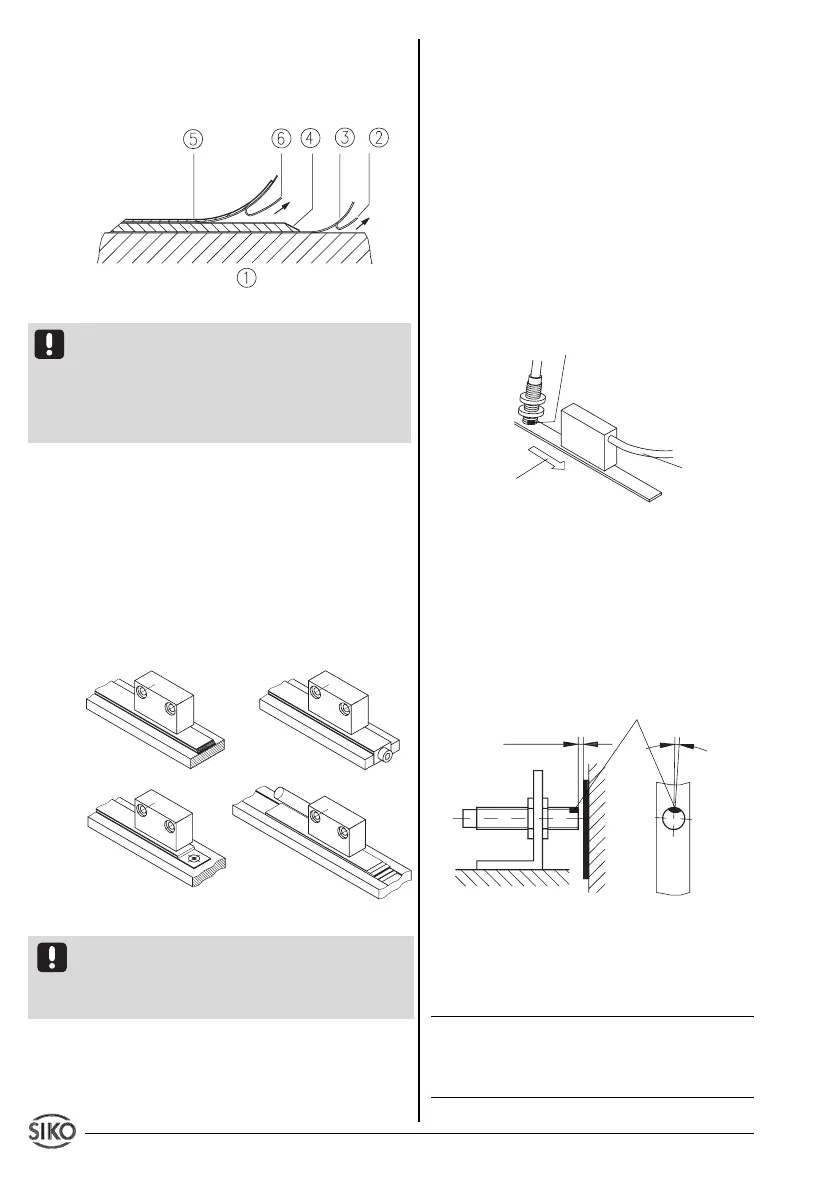

• Sensor must be aligned correctly with

respect to the counting direction (see fig. 6).

1

Precondition: Parameter 'Counting direction' (_dir_) in pro-

gramming mode must be programmed to "dn",

Fig. 6: Definition of counting direction / mounting

• When mounting the magnetic sensor, ensure

that the gap between strip and sensor and the

max. admissable deviation are maintained over

the total measuring length! (see fig. 7 and 8)

Fig. 7: Mounting of sensor Typ F

The gap between sensor and magnetic strip

should according to the following table.

type of display gap

EG10 0.1 ... 2 mm

TF 0.1 ... 2 mm

TS 0.1 ... 2 mm

Tab. 1: gap between sensor and magnetic strip

counting

direction

positive

1

travel direction

sensor

cable outlet

red marking

Signal

B before A

Sensor A,B or L

Sensor F

0.1 ... 2mm

<3°

red marking

Loading...

Loading...