- 20 -

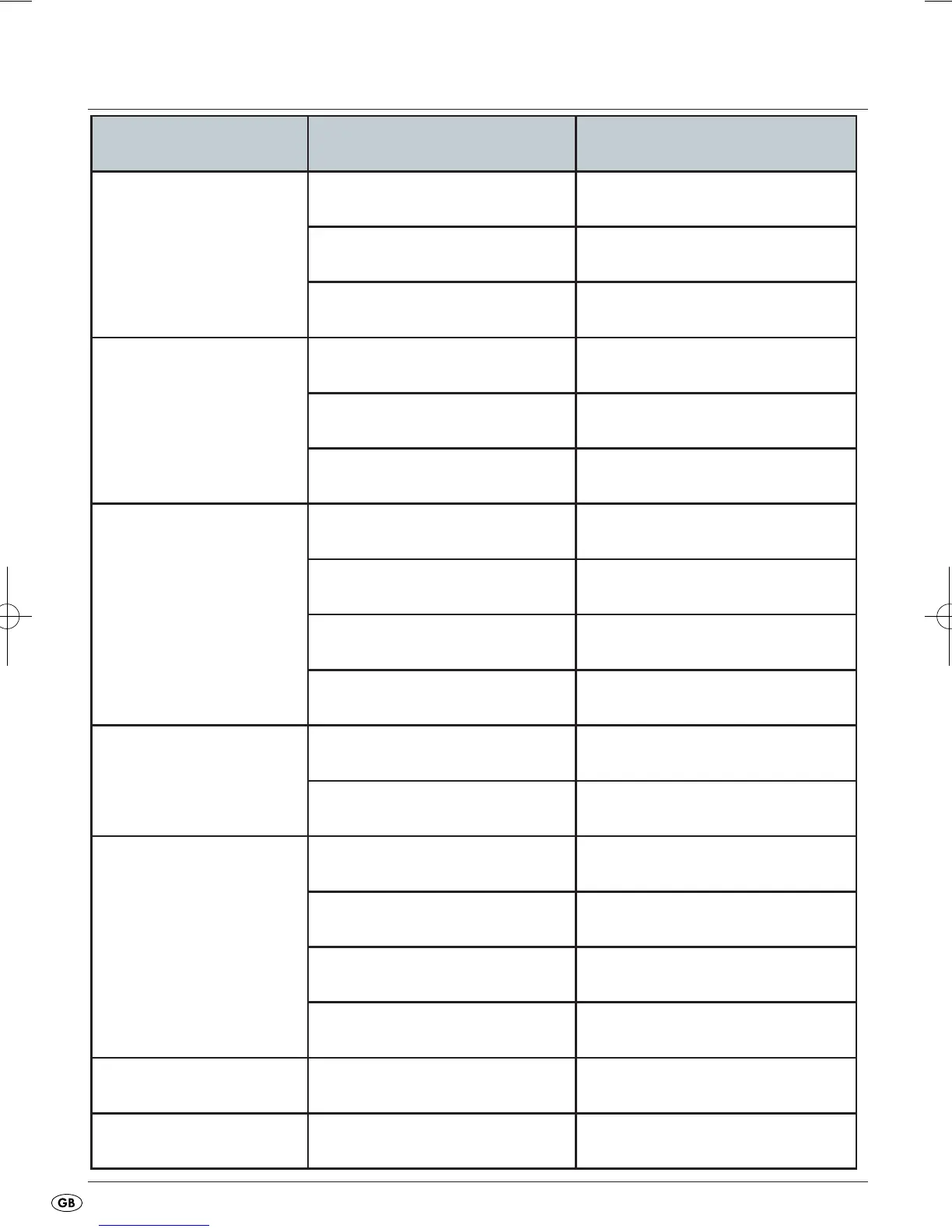

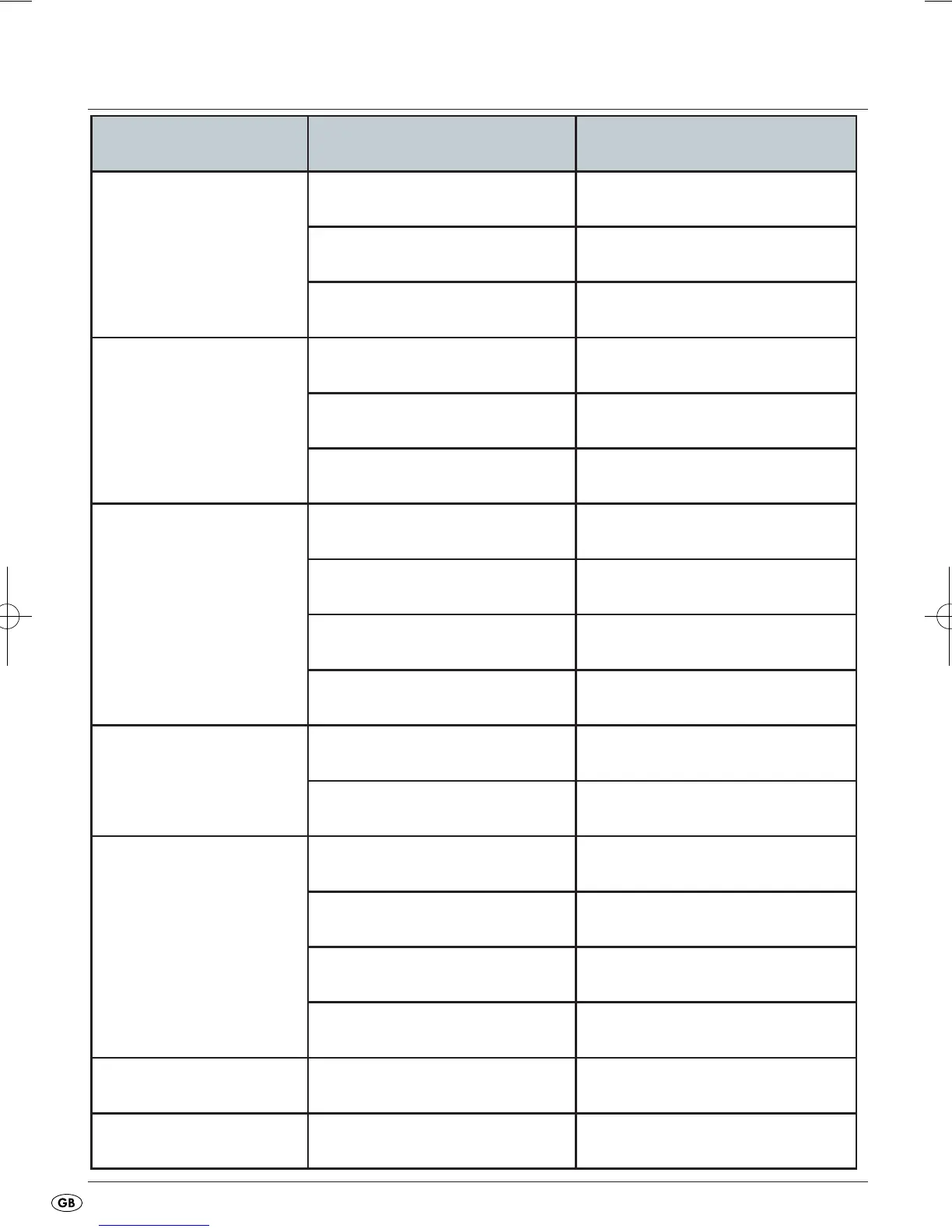

Troubleshooting

Problem Cause Solution

Needles break

• Needles are bent, blunt or da-

maged at the points.

• Fit new needles.

• Needles are not correctly inserted.

• Insert the needles into the retainers

correctly.

• You have pulled the material too

heftily.

• Carefully guide the material with

both hands.

Thread breaks

• Yarn has not been correctly

threaded.

• Thread the yarn correctly.

• Thread tension is too high. • Reduce the thread tension.

• Needles are not correctly inserted.

• Insert the needles into the retainers

correctly.

Stitches are omitted

• Needles are bent, blunt or da-

maged at the points.

• Fit new needles.

• Needles are not correctly inserted.

• Insert the needles into the retainers

correctly.

• Yarn has not been correctly

threaded.

• Check the course of the individual

threads.

• Incorrect needles are fitted.

• Use the correct needles (HA x 1

or 130/705H)

Stitches are irregular

• Thread tension is not correct. • Correct the thread tension.

• Thread is trapped.

• Check the course of the individual

threads.

Seams cause wrinkles

• Thread tension is too high. • Adjust the thread tension.

• Yarn has not been correctly

threaded.

• Thread the yarn correctly.

• Thread is blocked.

• Check the course of the individual

threads.

• Differential feed motion not

adjusted.

• Place the differential feed motion

at "S".

Material is not cut off cleanly

• Upper blade a is blunt or in-

correctly inserted.

• Change the blade a or insert it

correctly.

Material edges ruffle them-

selves

• Too much material in a stitch. • Alter the seam width.

Loading...

Loading...