Air Angle Grinder 196512

7

silverlinetools.com

WARNING: DONOTovertighten.Thedirectionofrotationwillpreventtheboltfrombecomingloose.

• Spin the disc by hand to check it is secure and correctly aligned

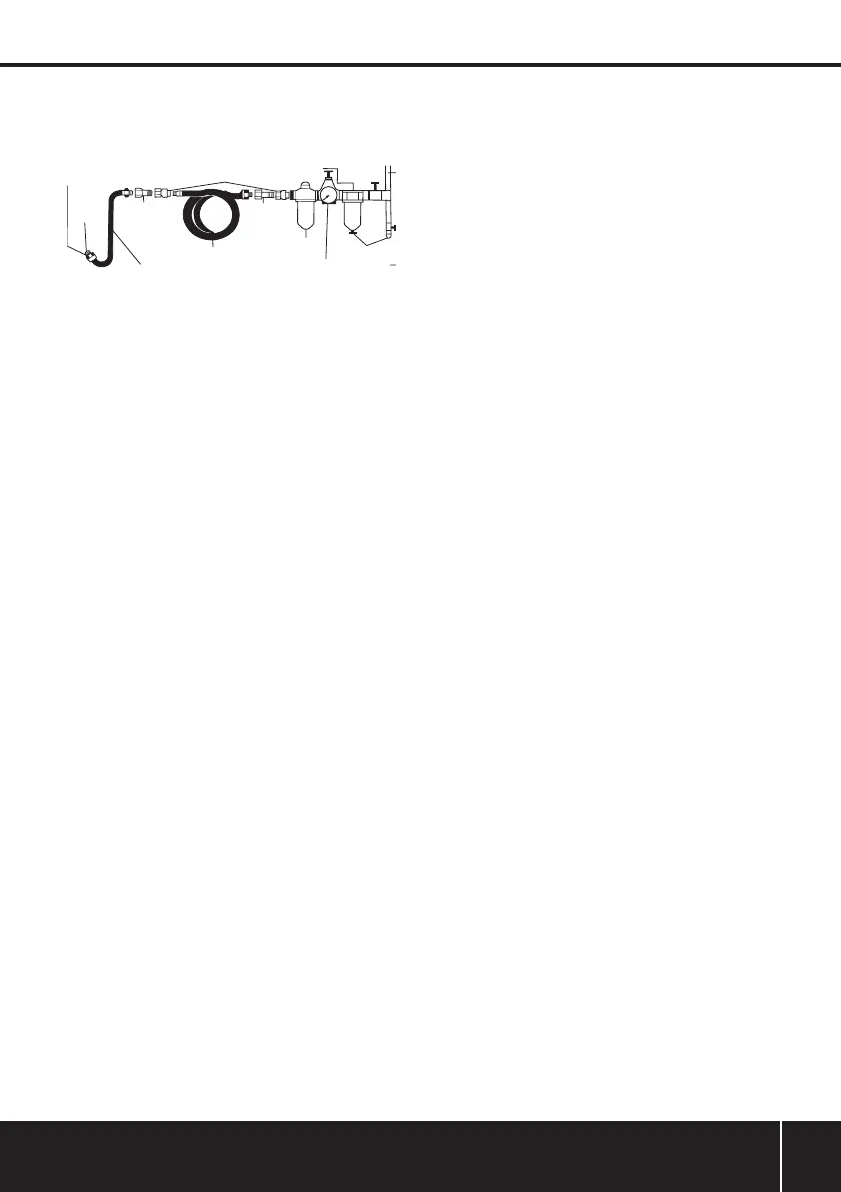

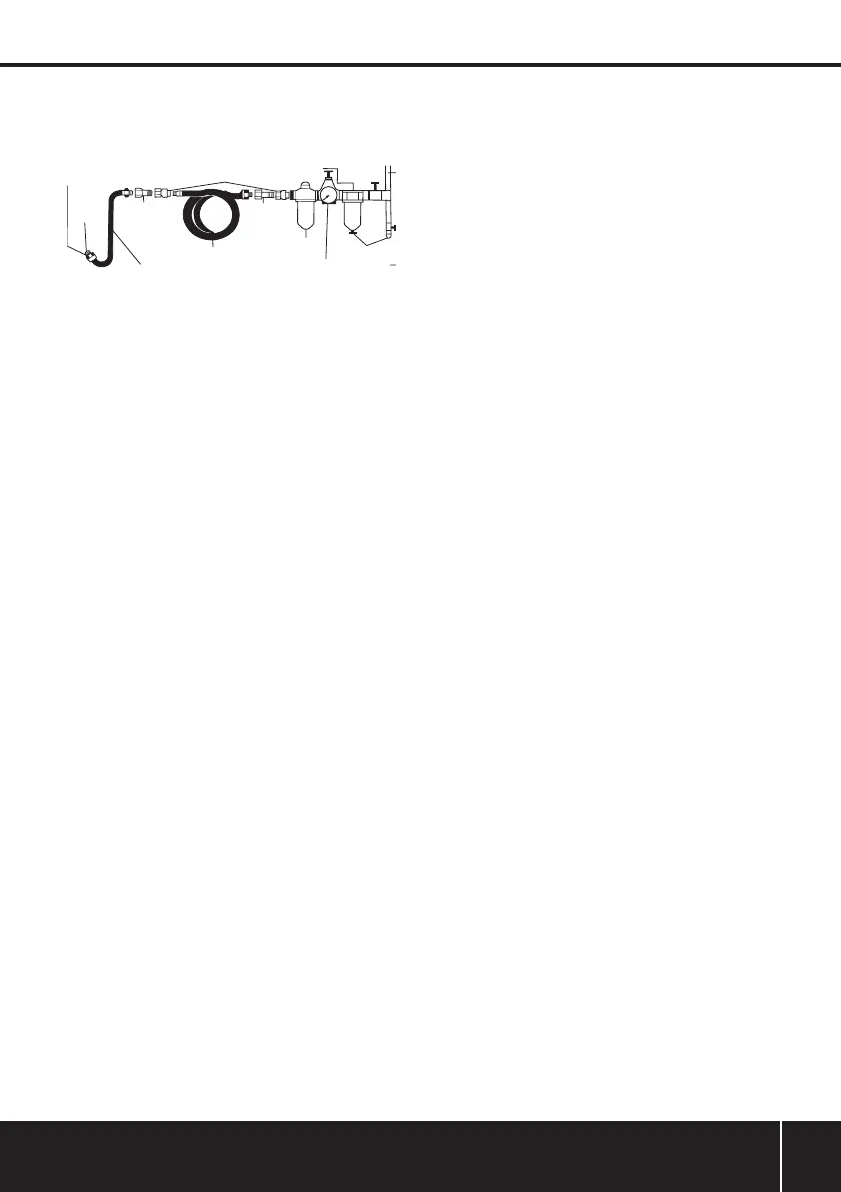

Air supply connection

• Thistoolshouldbeconnectedtoaclean,dryairsupplywithinlineoilerandwaterseparator

• Donotallowsupplypressuretoexceedthemaximumstated(see‘Specications’)

• Ensurethatwaterisdrainedfromairsystemdaily

• Ensure all parts of the system (hoses, couplers, etc.) are correctly rated for the air pressure to

be used

Setting tool power

• Themaximumtoolspeed/powercanbeadjustedbyreducing/increasingtheairsupplypressure

withintherangespeciedin‘Specications’

• Whilstworkingwiththetool,speedadjustmentscanbemadeviatheSpeedControlTrigger(10)

Operation

WARNING: DONOTswitchthemachineon/offwhenthediscisincontactwiththeworkpiece.Always

allowthemotortoreachitsfullspeedbeforeapplyingload,andtostopcompletelybeforeplacing

thegrinderdown.Alwaysholdthemachinesecurely,usingbothhands,onthehandlesprovided.

1. HoldthetoolbyitsHandle(1)andturnitsotheopensideoftheGuard(2)isfacingawayfrom

you.YourthumbshouldwraparoundthehandleandyourngersshouldsitontheSpeed

Control Trigger (10)

2. DisengagetheSafetyCatch(9)andgentlysqueezethetriggertowardsthehandle

3. TheGrindingDisc(5)willbegintospin.Squeezethetriggerfurthertoincreasethespeed;

slightly release to decrease the speed

4. Withthediscspinningattherequiredspeed,slowlymovethedisctowardstheworkpiece,and

gently engage the material

WARNING:Whenthediscbeginstocut/grind,itwillforcethetooltomovesideways.Makesureyou

havearmgriponthetoolandarereadytocounteractthis.

5. Asthediscbeginstocut/grind,takenoteofthedirectioninwhichthewastematerialisbeing

ejected.Itshouldbedirectedawayfromyou,andnottowardsanypersonorobjecttowhichit

may cause damage

6. Tostopthetool,removethediscfromtheworkpiece,fullyreleasethetriggerandallowthesafety

catch to re-engage

Note: DONOTallowthetooltorunin‘idlerotation’foranextendedperiodoftime.Thiswill

shorten its life.

WARNING: Beawarethatairtoolsmayholdresidualpressureafteruse.Alwaysbleedairpressure

from the tool after shutting off air supply.

Grinding

• Onlyusediscsspecicallymanufacturedforgrindingoperations.Stoneandmetalgrindingdiscs

are not interchangeable; use the correct disc for your application

• Whengrinding,holdthetoolata15°to30°angletothesurfaceoftheworkpiece(Fig.A)

Note:Donotapplytoomuchpressuretothemachinewhilstgrinding.Excessivepressuredoesnot

resultinmoreeffectiveremovalofmaterial,butwillcauseprematurewearofthegrindingdiscand

increasedwearandtearonthemachine.

Cutting

• Onlyusediscsspecicallymanufacturedforcuttingoperations.Stoneandmetalcuttingdiscsare

not interchangeable, use the correct disc for your application

• Never use cutting discs for grinding operations. The disc might shatter and produce projectiles

that could injure the operator and bystanders

• Whencutting,alwayskeeptheangleofthediscconstant.Donotapplyanysidewaysforceto

cutting discs, as this might lead to the disc becoming jammed in the cut and shatter

WARNING:Donotapplytoomuchpressuretothemachinewhilstcutting.Excessivepressuredoes

notresultinmoreeffectiveorfastercutting,butwillinfactcauseprematurewearofthecuttingdisc

andincreasewearandtearonthemachine.

Note: Thecuttingdiscwillwearduringuse,andthediscdiameterwillgraduallyreduceinsize.

Thesmallerthediscbecomes,themorestrainwillbeplacedonthemotor.Toavoiddamagetothe

machine,onlyusecuttingdiscsthatarewithinapproximately25%oftheoriginalsize.

Accessories

• Accessories for this tool, including grinding and cutting discs, are available from your Silverline

stockist. Spare parts can be obtained from your Silverline dealer or www.toolsparesonline.com

Maintenance

WARNING:Alwaysdisconnectfromtheairsupplyanddepressurisebeforecleaningorcarryingout

any maintenance.

Cleaning

• Keepyourtoolcleanatalltimes.Dirtanddustwillcauseinternalpartstowearquickly,and

shortenthemachine’sservicelife.Cleanthebodyofyourmachinewithasoftbrush,ordrycloth

IMPORTANT: Thereisverylittlethatcangowrongwithyourairtoolanditshouldbenotedthat

whenanairtoolfailstoworkitisgenerallybecausetheinternalworkingshavecorrodeddueto

dirty,wetairandfailuretofollowtheinstructionsgivenbelow.

Daily maintenance procedure: Disconnect from the air supply, pour the equivalent of a

tablespoonofoilintotheairintake.Operatethemachineatlowspeedtothoroughlylubricateall

internalworkings.

• Ifthemachineisinconstantuseorusedforlongperiodsatatime,acombinedlter/lubricator

mustbetted.Theremustbeanairlterttedatalltimes

• Use air tool oil. DO NOT UNDER ANY CIRCUMSTANCES USE NORMAL ENGINE OIL

• Failuretocomplywiththeoperatingandmaintenanceinstructionsmayinvalidatetheguarantee

Contact

For technical or repair service advice, please contact the helpline on (+44) 1935 382 222

Web: silverlinetools.com/en-GB/Support

Address:

Powerbox

Boundary Way

Lufton Trading Estate

Yeovil, Somerset

BA22 8HZ, United Kingdom

Storage

• Store this tool carefully in a secure, dry place out of the reach of children

Disposal

• Aswithotherpowertools,airtoolsshouldnotbedisposedofwithhouseholdwaste

• Air tools may contain traces of tool oil and other lubricants and so must be recycled accordingly

• Contactyourlocalwastedisposalauthorityforinformationonthecorrectwaytodisposeof

powertools

DO NOT INSTALL

TO YOUR

AIR TOOL

LEADER HOSE

NIPPLE

QUICK COUPLER

OILER

NIPPLE

REGULATOR

DRAIN DAILY

AIR SUPPLY

RECOIL HOSE

196512_Manual.indd 7 30/08/2017 17:20

Loading...

Loading...