7. Clean away the old grease from the interior

of the ice breaker and inspect the bearing pressed

into the top of the ice breaker and if worn do not

hesitate to replace it.

8. Inspect the conditions of the O ring; if torn or

worn replace it.

WARNING. The top bearing assembly

works in critical conditions for what

concern its lubrication as it is haused in

the ice breaker where the formation of

condensation is usual. Therefore it is

important to apply on it an ample coating

of Food grade Waterproof Grease before

installing the breaker and cap hook in

place

.

9. Slide off from the auger bottom the upper

half of the water seal.

NOTE. Any time the auger is removed for

replacement or inspection use extra care in

handling the water seal parts, so no dirt or

foreign matters are deposited on the surfaces

of the seal. If there is any doubt about the

effectiveness of the water seal or O ring do

not hesitate to REPLACE THEM.

10. Unloose and remove the three/four bolts

which attach the freezer assy to the aluminium

adaptor.

11. Raise the freezer assy off the adaptor,

secure it out of the way to allow room to work. On

SP125-255 using a suitable lenght and size wooden

dowel or stick inserted through the top of the

open freezer, tap the lower half of the water seal

and the lower bearing out the bottom of the

freezer.

12. On the superflaker models, with two

screwdrivers as a lever, remove from the bottom

of the freezer assy the lo bearing brass holding

ring.

NOTE. It is good practice to replace the water

seal assy and both the top and the bottom

bearings any time the auger is removed.

To facilitate this it is available a service Kit

(P/N 001028.07 for SP125-255 and

P/N 001028.08 for SP N405-6 05- 1205) which

includes besides the above mentioned parts,

the ice breaker O ring and a tube of food

grade waterproof grease.

13. Reach through the adaptor and remove the

coupling parts.

14. Check both the coupling halves for chipping

and wear and do not hesitate to replace them.

15. Install the bottom bearing into its brass

housing paying attention to have the white plastic

ring facing up.

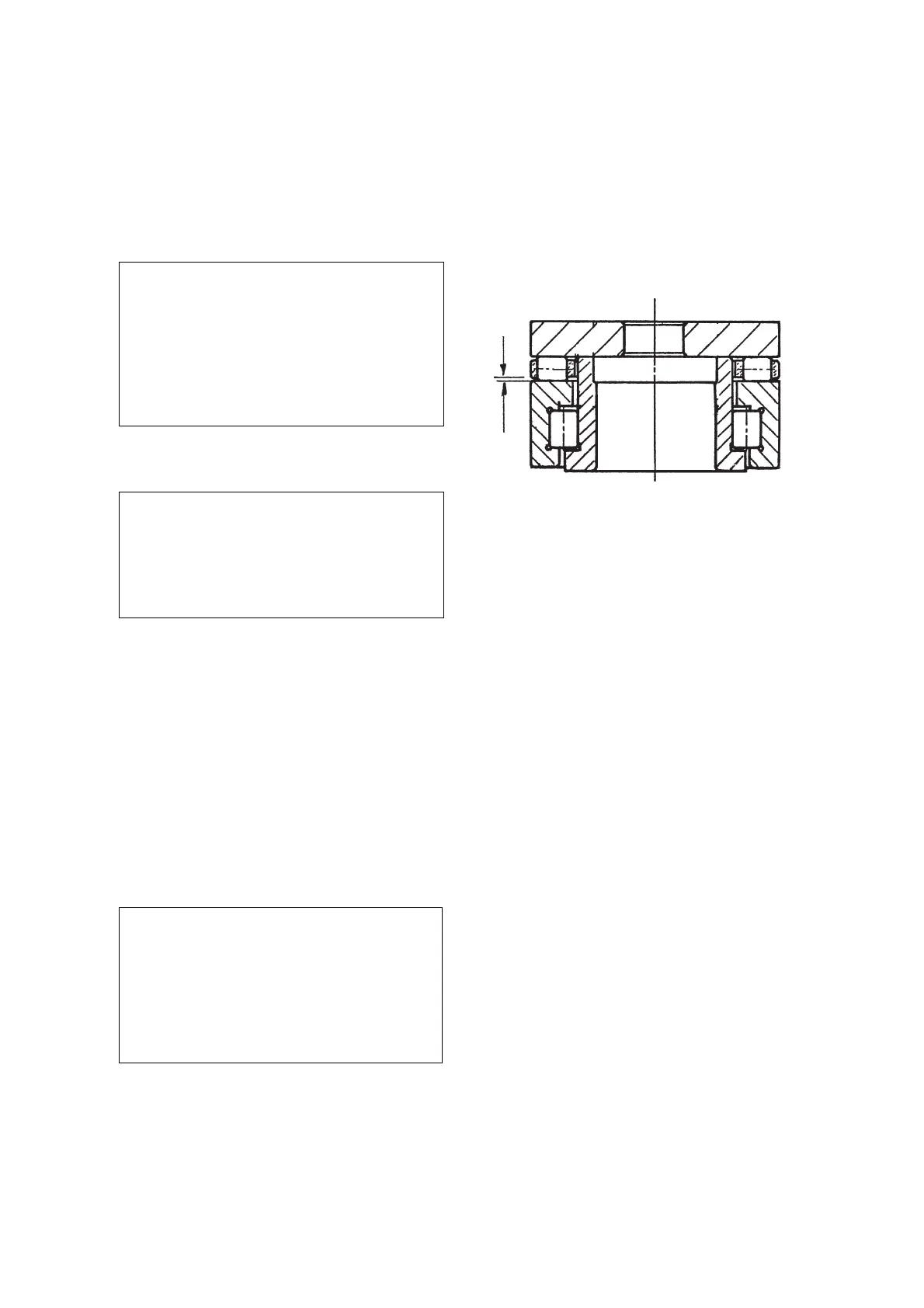

16. Install the upper bearing into the ice breaker

starting by the radial portion that must be fitted

with the flat surface facing up.

17. Apply some lubricant (grease) on the upper

surface then install the rollers cage with the

smaller openings of the same facing up so to

leave a small gap between plastic cage and flat

surface of the botton portion of the bearing (see

drawing).

18. Apply some move lubricant then place the

S.S. trust washer.

19. After to have replace the O ring into the ice

breaker fit the same on top of the auger and

secure it with the top bolt.

20. Install the auger/icebreaker into the

evaporator following the previous steps in

reverse.

J. REPLACEMENT OF THE GEAR MOTOR

ASSY

1. On SP125-255, SP405-605 remove the

front/top and side/rear panels and on SPN1205

remove the front, rear, top and left side panels.

2. Remove the three/four bolts and washers

securing the gear reducer base to the unit chassis,

then remove bolts and lockwashers which attach

the bottom of the aluminium adaptor to the gear

reducer case cover.

3. Follow the steps of item E to remove the

gear motor magnetic sensor.

4. Trace and disconnect the electric wires

leads of the drive motor. Lift and remove the

entire gear motor assembly.

5. To install the replacement gear motor assy

follow the above steps in reverse.

K. REPLACEMENT OF FAN MOTOR

1. Remove the front/top and side/rear panels

on models SP125-255, SPN405-SPN605 and the

front panel on model SPN 1205.

2. Remove screws and yellow green ground

wire. Trace the electrical leads of fan motor and

disconnect them.

Page 32

Loading...

Loading...