X-Press

Operating Instructions

32

Regularly examine hub caps,

seals and pivot bolts and all

tracking bolts for tightness and

effectiveness twice weekly or

every50workinghours(whichever

ismorefrequent).

5. Servicing and

Maintenance

Followthesafetyinstructionsfor

servicingandmaintenance.

5.1 Servicing

Your machine has been designed and

constructed for maximum performance,

operational efficiency and operator

friendlinessunderawidevarietyofoperating

conditions.

Prior to delivery, your machine has been

checkedatthefactoryandbyyourauthorised

dealertoensurethatyoureceiveamachine

inoptimumcondition.

To ensure trouble-free operation,

it is important that servicing and

maintenanceworkisperformedat

therecommendedintervals.

5.2 Cleaning

In order to ensure that the machine is

alwaysinoperatingconditionandtoachieve

optimumperformance,performthecleaning

andservicingworkatregularintervals.

Avoidcleaningtheroll/discbearingswith

ahigh-pressurehoseoradirectwaterjet.

Thehousing,screwedconnectionsandball

bearingsarenotwatertight.

5.3 Disc Hub

Maintenance

Greaseeverydischubuntilgrease

showsfromthesealsaccordingto

the lubricating intervals outlined

onpage36.

Check disc hubs regularly for

tightness.

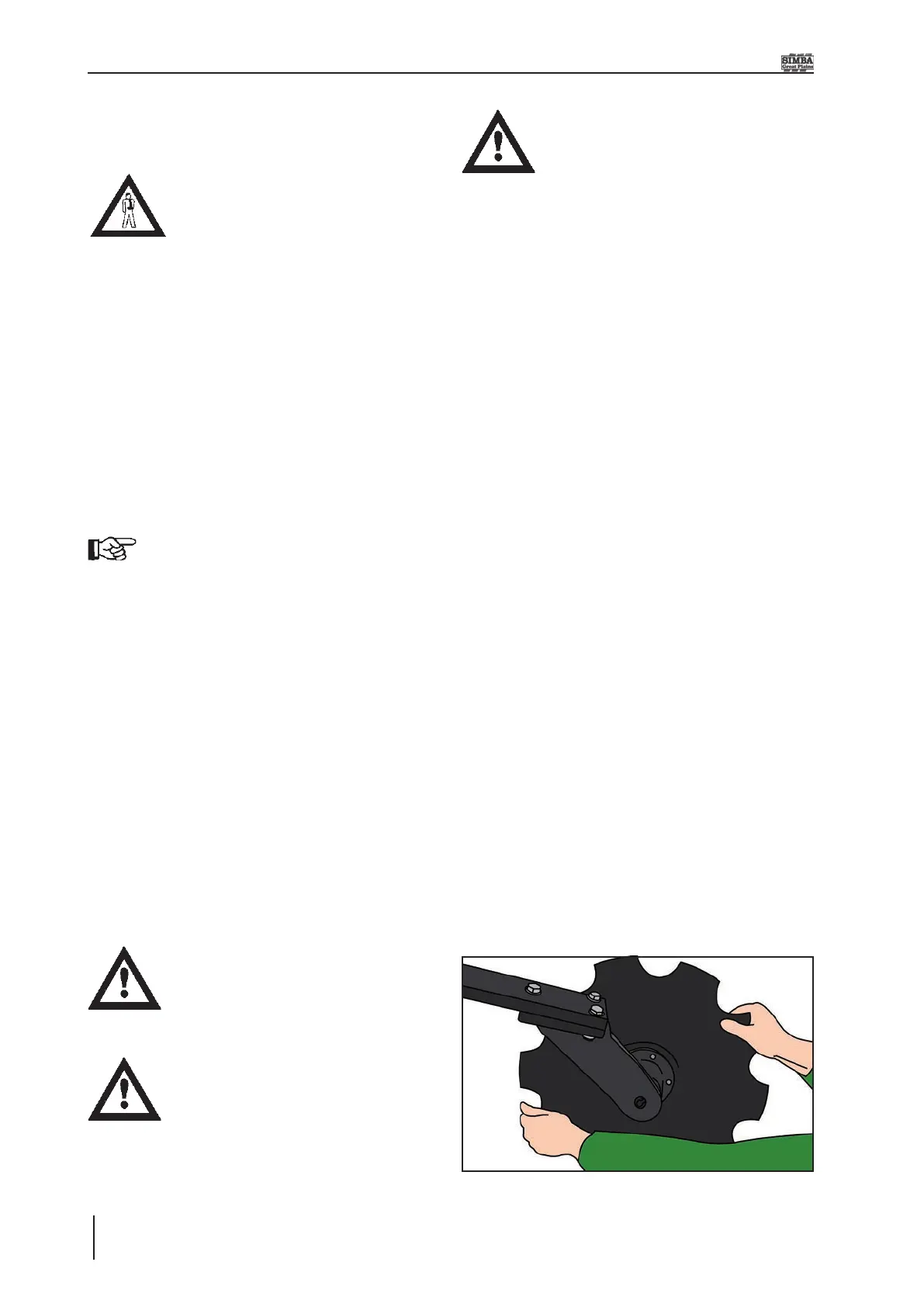

Fig. 5.01: Checking Disc Bearing Adjustment

1 Ensurethatthebearingsealisinthe

correct orientation when replacing /

assemblingcomponents.

2 Ensurethatthestubaxleisfreefrom

dirtandthenutandouterbearingcan

easilyslideonit.

3 Tighten the crown nut with a hand

spanner (a torque wrench is not

required) while turning the hub

clockwise until the bearing drags

slightly (you feel the hub turning

heavily).Someresistancewillbedue

tofrictionfromtheseal.

4 Turn back the crown nut to the next

lockingposition.Evenifthetightening

ofthenuthasreachedanexactxing

position,turnitback.

5 Inserttheretainingpin.

6 Trytoshake/rocktheouteredgeofthe

hub/spindle:play of 0.1/ 0.2mm will

not reduce the bearings’ life and, in

addition,preventsoverheating.Ifthe

adjustmentiscorrectthehubshould

turnfreelywiththeonlyfrictionbeing

fromtheseal.

5.3.1 Tightening Disc Hubs

Å

Å

Å

Å

5.ServicingandMaintenance

Loading...

Loading...