12

This means that the efficiency of the

system will deteriorate as corrosion

sludge accumulates within the system,

risking damage to pump and valves, boil-

er noise and circulation problems.

–

For optimum performance after instal-

lation this boiler and its associated cen-

tral heating system must be flushed in

accordance with the guidelines given in

BS 7593 “Treatment of water in

domestic hot water central heating

systems”.

Sime Ltd recommend only the use of

FERNOX products for the flushing and

final treatment of the system water.

This is particularly important in hard

water areas.

Artificially softened water must not be

used to fill the heating system.

Failure to flush and addinhibitor to the

system may invalidatethe appliance

warranty. For the correct operation of

the aluminum heat exchanger make

sure that the chemical/physics char-

acteristics of the system water have a

PH value within 6,5 and 8.

– It is important to check the inhibitor

concentration after installation, system

modification and at every service in

accordance with the manufacturer’s

instructions (Test kits are available from

inhibitor stockists).

– At every service the Aquaguard Filter

(4.5.2) should be checked and cleaned.

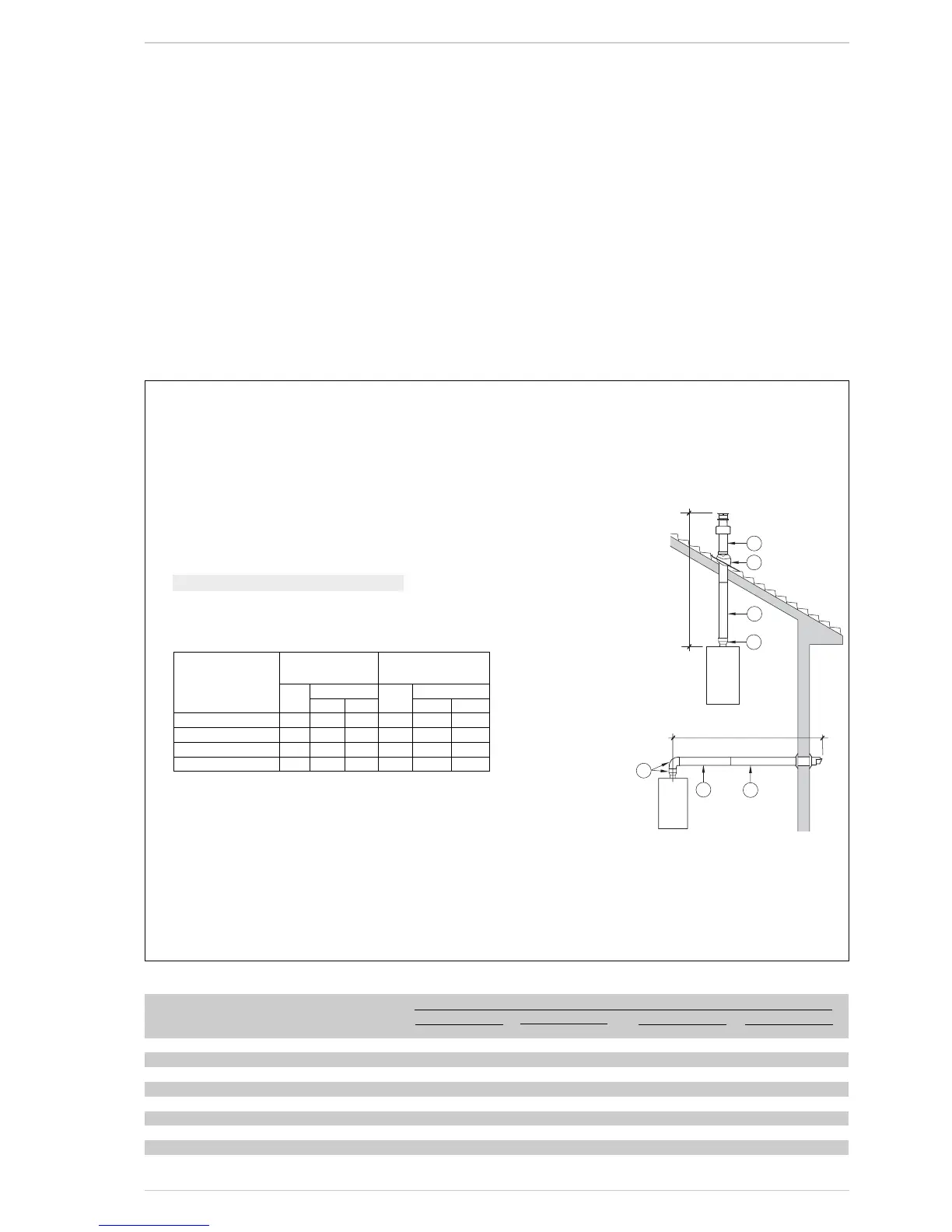

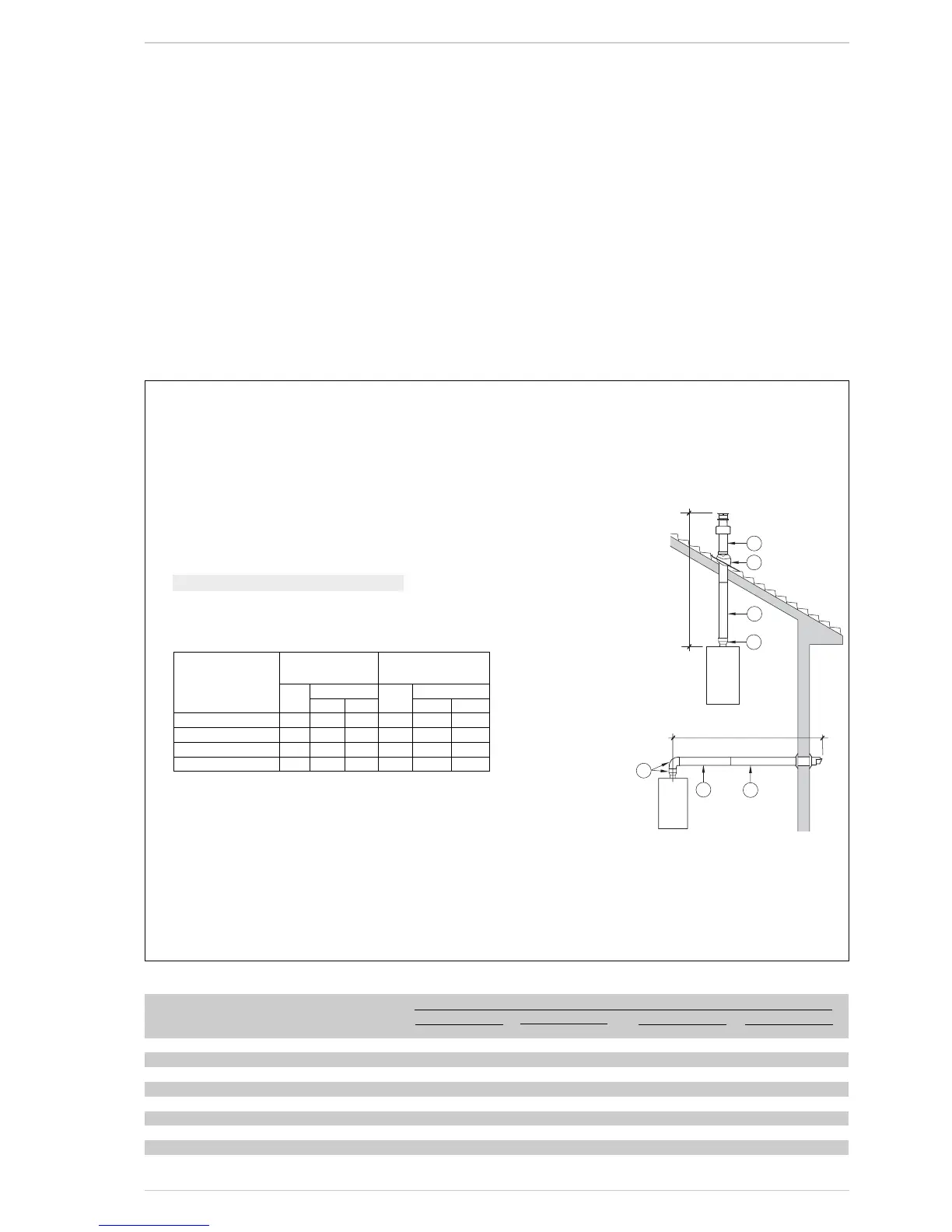

2.5 INSTALLATION OF

COAXIAL DUCT

ø 60/100 - ø 80/125

(fig. 6)

The coaxial suction and discharge pipes are

supplied in a special kit (that can be purcha-

sed separately) along with assembly

instructions.

The diagrams of fig. 6 illustrate some

examples of different types of fluing options

allowed and the maximum lengths that can

be reached.

LIST OF ø 60/100 ACCESSORIES

1 Coaxial duct kit L. 790 code 8 091212

(includes 8086950)

2a Extension L. 1000 code 8096150

2b Extension L. 500 code 8096151

3 Vertical extension L. 140 with coupling code 8086950

5 Tile for joint code 8091300

6 Terminal for roof exit L. 1285 code 8091212

(includes 8086950)

Model Length of pipe Length of pipe

ø 60/100 ø 80/125

HV H V

Min Max Min Max

20 SYSTEM 6 m 1.3 m 8 m 12 m 1.2 m 15 m

25 6 m 1.3 m 8 m 12 m 1.2 m 15 m

30 5 m 1.3 m 7 m 10 m 1.2 m 13 m

35 4 m 1.3 m 6 m 10 m 1.2 m 13 m

LIST OF ø 80/125 ACCESSORIES

1 Coaxial duct kit L. 785 code 8091205A

(includes 8093150)

2a Extension L. 1000 code 8096171

2b Extension L. 500 code 8096170

3 Adapter for ø 80/125 code 8093150

5 Tile for joint code 8091300

6 Terminal for roof exit L. 1285 code 8091205A

(includes 8093150)

H (Horizontal) m

V (Vertical) m

IMPORTANT:

– The insertion of each additional 90° bend with a diameter of 60/100 (code 8095850)

reduces the available section by 1.5 meters.

– The insertion of each additional 90° bend with a diameter of 80/125 (code 8095870)

reduces the available section by 2 meters.

– Each additional 45° curve installed a diameter of 60/100 (code 8095550) reduces the

available length by 1.0 metres.

– Each additional 45° curve installed a diameter of 80/125 (code 8095970) reduces the

available length by 1.0 metres.

HORIZONTAL FLUES MUST BE LEVEL

NOTE: Before connecting accessories, it is always advisable to lubricate the internal part of

the gaskets with silicon products. Avoid using oils and greases.

TABLE 3 - ACCESSORIES ø 80

Accessories ø 80 Total head loss (

mm H

2

O)

20 25 30 35

Inlet Outlet Inlet Outlet Inlet Outlet Inlet Outlet

Air/smoke divider – – – – – – – –

90° elbow MF 0.15 0.20 0.20 0.25 0.25 0.30 0.30 0.40

45° elbow MF 0.10 0.10 0.15 0.15 0.20 0.20 0.25 0.25

Extension L. 1000 (horizontal) 0.10 0.10 0.15 0.15 0.20 0.20 0.25 0.25

Extension L. 1000 (vertical) 0.10 0.10 0.15 0.15 0.20 0.20 0,25 0.25

Wall terminal 0.05 0.20 0.10 0.25 0.10 0.35 0.15 0.50

Wall coaxial exhaust

*

Roof outlet terminal * 0.50 0.05 0.80 0.10 1.10 0.15 1.50 0.20

* This loss includes the loss of the adaptor 8091401

Fig. 6

Loading...

Loading...