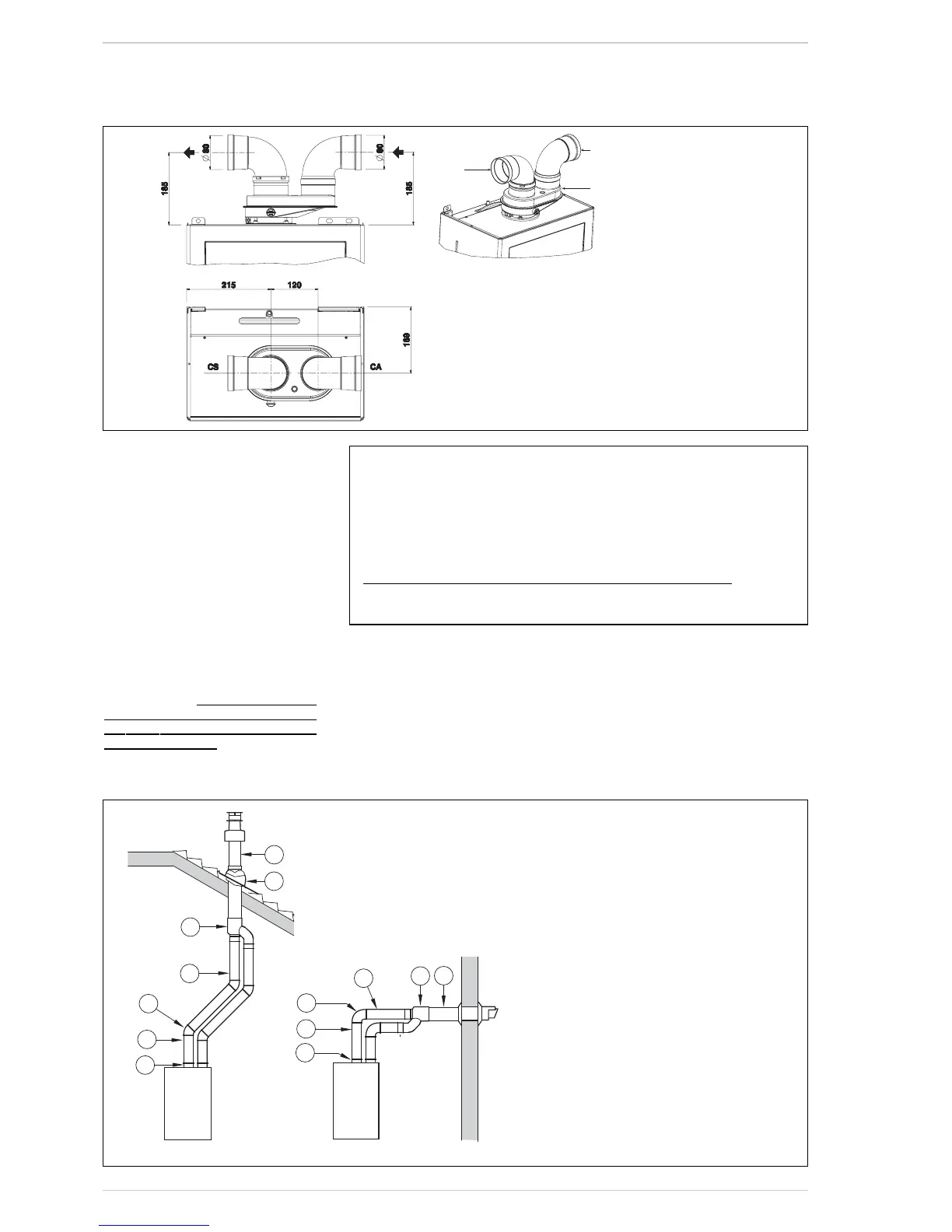

2.6 INSTALLATION OF SEPARATE

DUCTS ø 80 (fig. 7 - fig. 7/a)

The kit with dedicated pipes enables to

separate the exhaust fumes pipes from the

air suction pipes (fig. 7):

–for ø 80 pipes, divider code 8093050 is

provided upon request.

The maximum overall length, resulting

from the sum of all the suction and

discharge pipes, is determined by the

load losses of the single connected acces-

sories and should not exceed 13 mm H2O

(version 20 System) - 15 mm H2O (ver-

sion 25-30-35) (ATTENTION: the total

length of each pipe should not exceed 50

m, even if the total loss is below the

maxi-

mum applicable loss.)

See Table 3 for information on the load los-

ses of single accessories and the example

of Fig. 7/a for information on how to calcu-

late load losses.

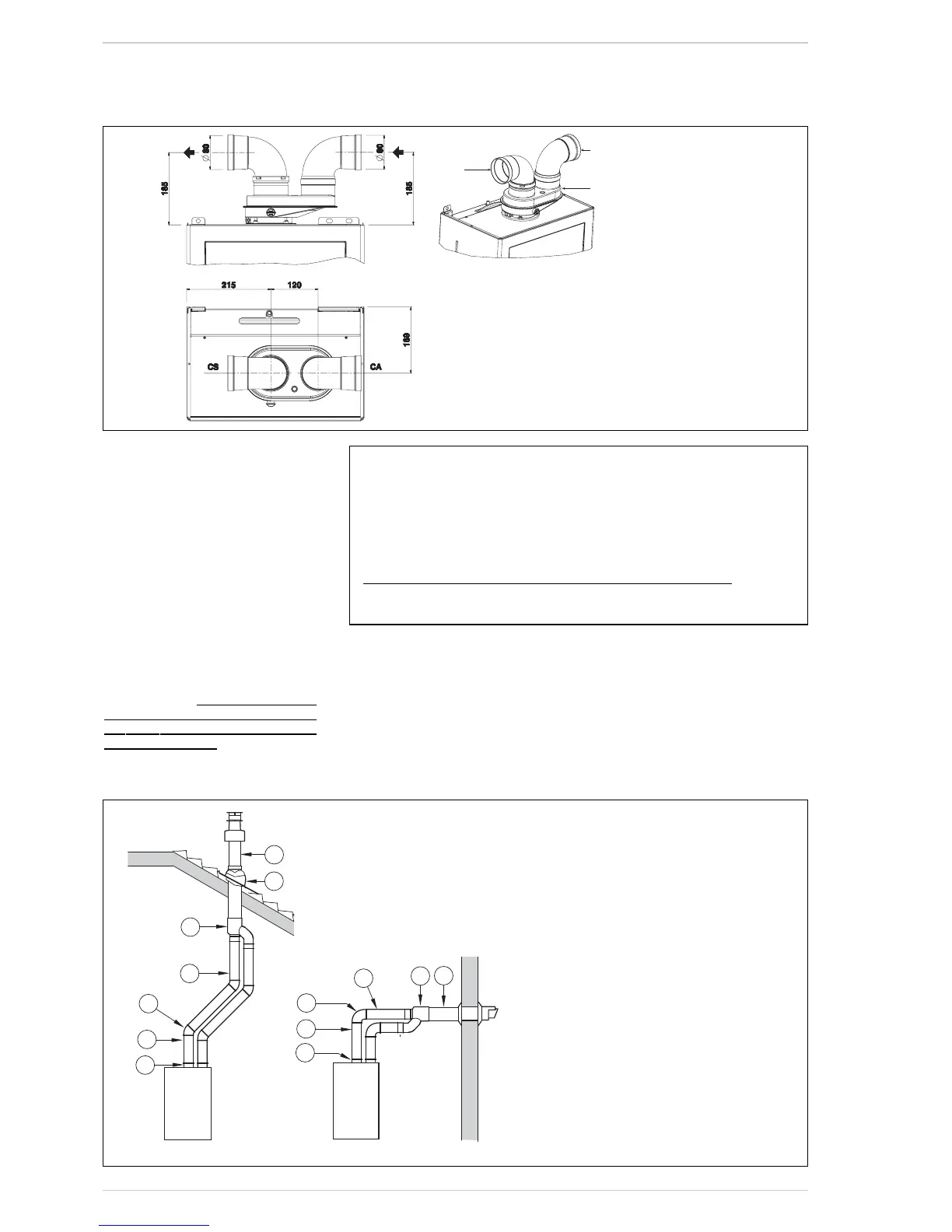

2.6.1 Separate ducts kit (fig. 8)

The diagrams of Figure 8 show a couple of

examples of the permitted exhausts confi-

gurations.

2.7 POSITIONING THE

OUTLET TERMINALS (fig. 9)

The outlet terminals for forced-draught

appliances may be located in the external

perimeter walls of the building.

To provide some indications of possible solu-

tions, Table 4 gives the minimum distances

to be observed, with reference to the type

of building shown in fig. 9.

NOTE

Before connecting accessories, it is always advisable to

lubricate the internal part of the gaskets with silicon

products. Avoid using oils and greases.

LIST OF ø 80 ACCESSORIES

1 Air/smoke divider code 8093050

3 a Extension L. 1000 code 8077351 (6 pz.)

3 b Extension L. 500 code 8077350 (6 pz.)

7 a Additional 45° MF curve code 8077451(6 pz.)

7 b Additional 90° MF curve code 8077450 (6 pz.)

9 Manifold, code 8091401

10 Tile for joint code 8091300

11 Terminal for roof exit L. 1381 code 8091205B

13 Union suction/exhaust code 8091401

14 Coaxial exhaust ø 80/125 L. 885 code 8096253

Loading...

Loading...