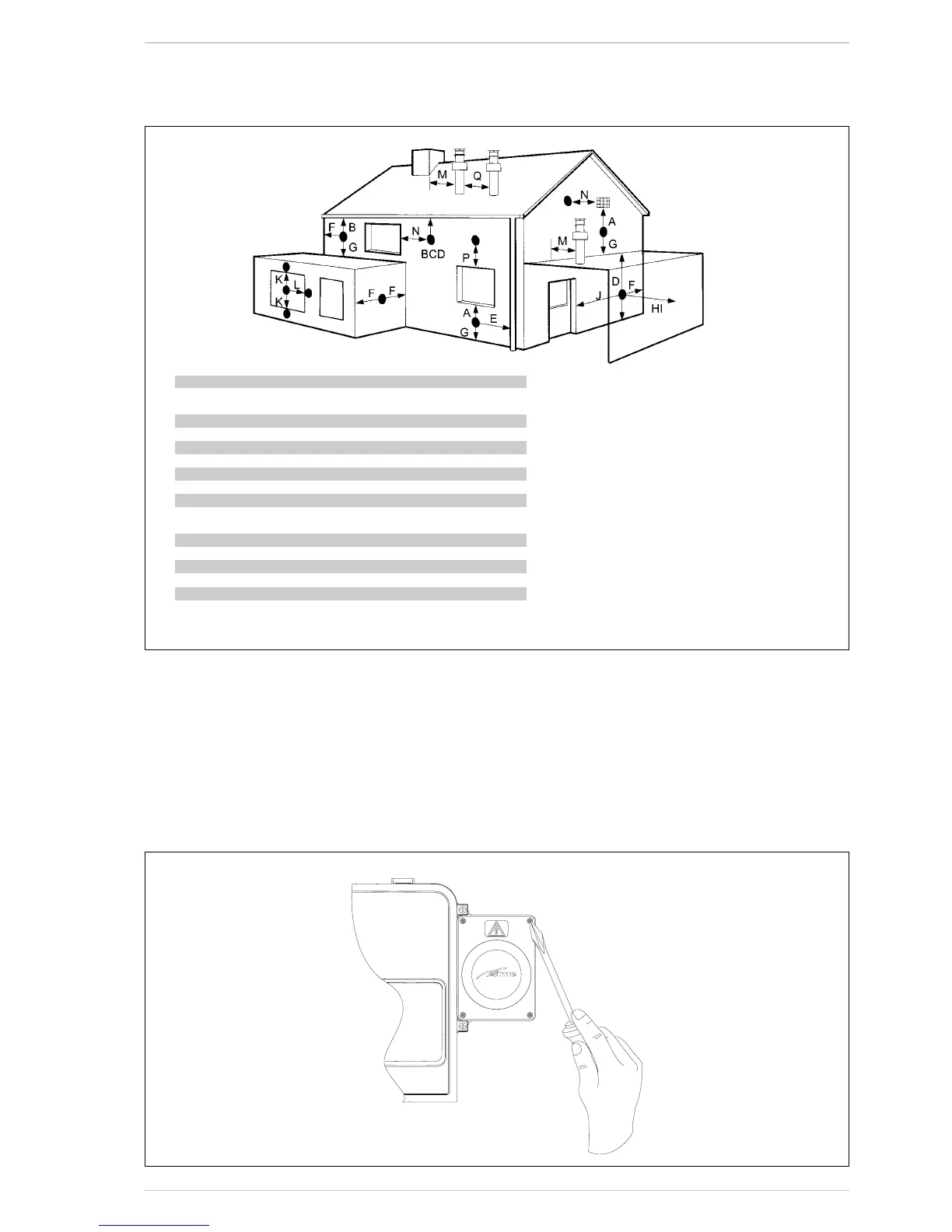

– If the terminal discharges into a pathway or passageway check

that combustion products will not cause nuisance and that the

terminal will not obstruct the passageway.

– Where the lowest part of the terminal is fitted less than 2 m

(78 in) above ground, above a balcony or above a flat roof to

which people have access, the terminal MUST be protected by

a purpose designed guard.

– Where the terminal is fitted within 850 mm (34 in) of a plastic

or painted gutter, or 450 mm (18 in) of painted eaves, an alu-

minium shield at least 1,500 mm (59 in) long must be fitted to

the underside of the painted surface.

– The air inlet/outlet flue duct MUST NOT be closer than 25 mm

(1 in) to combustible material.

– In certain weather conditions the terminal may emit a plume of

steam. This is normal but positions where this would cause a

nuisance should be avoided.

Terminal position Minimum spacing

A Directly below an openable window, air vent

or any other ventilation opening 300 mm 12 in

B Below guttering, drain pipes or soil pipes (*) 75 mm 3 in

C/D Below eaves, balconies or carport roof 200 mm 8 in

E From vertical drain pipes or soil pipes 75 mm 3 in

F From internal or external corners 300 mm 12 in

G Above adjacent ground, roof or balcony level 300 mm 12 in

H From a boundary or surface facing the boiler 600 mm 24 in

I From a terminal facing the terminal 1,200 mm 48 in

J From an opening in the carport

(eg door, window into dwelling) 1,200 mm 48 in

K Vertically from a terminal on the same wall 1,500 mm 60 in

L Horizontally from a terminal on the same wall 300 mm 12 in

M Horizontally from a vertical terminal to a wall 300 mm 12 in

N Horizontally from an openable window or other opening 300 mm 12 in

P Above an openable window or other opening 300 mm 12 in

Q From an adjacent vertical terminal 600 mm 24 in

(*) For condensing boilers this distance can be reduced to 25 mm without effecting boiler per-

formance, but it will be necessary to protect the surfaces from the effects of condensate

TABLE 4

Fig. 9

14

2.8 INSTRUCTIONS FOR

ASSEMBLY OPTIONAL

CLOCK PART

NUMBER 8092242

(fig. 23/a - 23/b - 23/c)

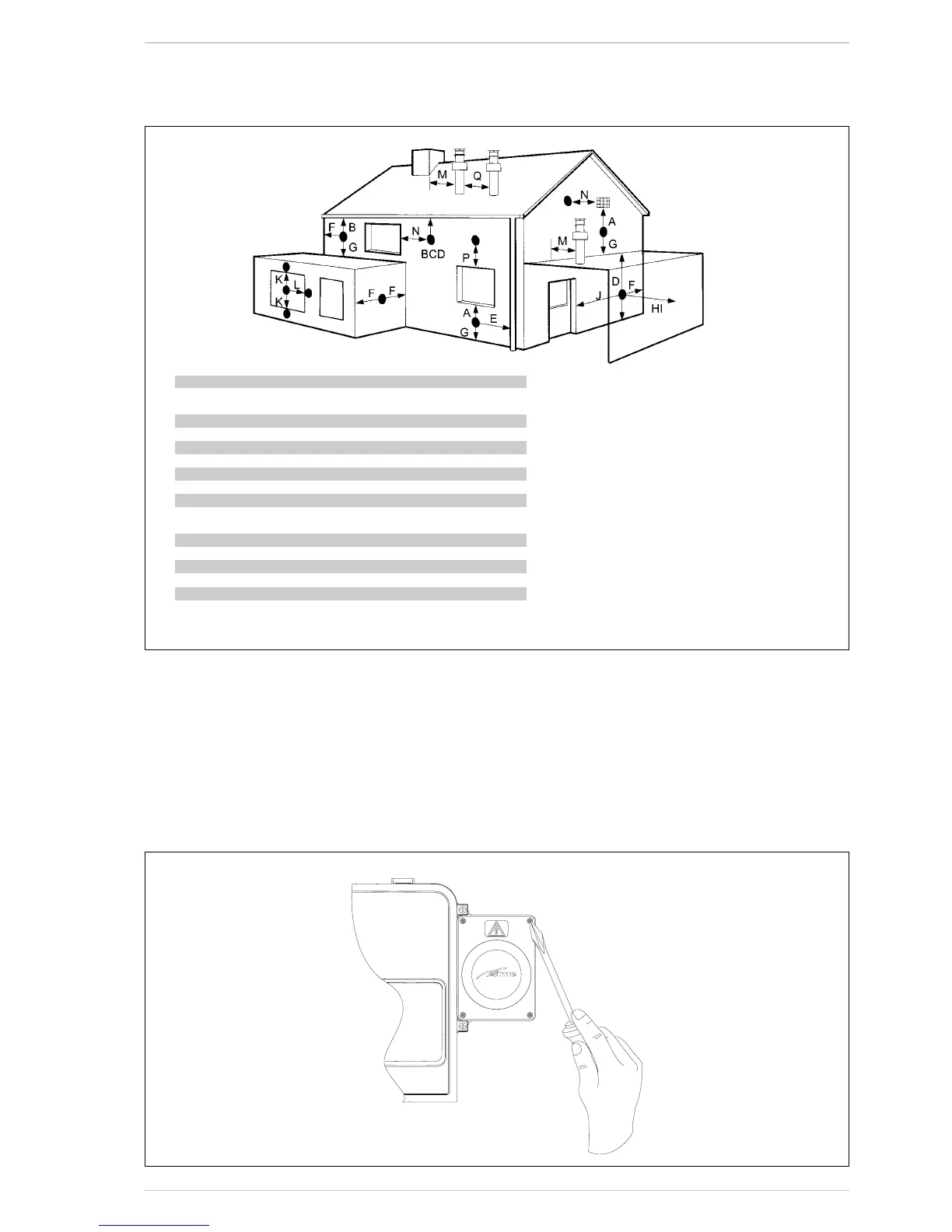

1) Isolate the power supply to the

boiler.

2) Remove the boiler cover.

3) Remove the time clock box cover

unscrewing the 4 screws (fig.

23/a).

IMPORTANT! RETAIN THE 4

SCREWS AS THESE ARE USED TO

FIX TIME CLOCK!

4) Inside the time clock box are 4

wires:

- 2 reds

- 1 brown

- 1 blue;

Remove the faston protections

and connect as shown on fig.

23/b.

5) Fix the Time clock with the 4

screws removed before (as

shown on fig. 23/c).

Fig. 23/a

Loading...

Loading...