22

When placing the magnet near the location (see Figure 16) indicated by a

“TEST” mark embossed on the cover, the visible LED flashes indicating the

detector's condition. The following are descriptions of what you should see

when using the MAG TEST.

• NORMAL - When in MAG TEST, the detector latches into alarm if the

detector is within calibration range and the visible LED stays ON.

• MORE SENSITIVE - When in MAG TEST, if the detector is more

sensitive than the maximum calibration, the visible LED quickly flashes,

twice a second. Following the sixth flash, the detector latches into alarm

and the visible LED stays ON.

• LESS SENSITIVE - When in MAG TEST, if the detector is less sensitive

than the minimum calibration, the visible LED slowly flashes four times,

once every two seconds. Following the fourth flash, the detector latches

into alarm and the visible LED stays ON.

• NON-FUNCTIONAL - If the detector is less sensitive than the minimum

allowable sensitivity, the visible LED does not flash normally. When in

MAG TEST, the visible LED slowly flashes four times, once every two

seconds. After the fourth flash, the detector does NOT latch into alarm and

the LED stops flashing and turns OFF.

If the detector is out of the normal operating range, it should be cleaned. If the

detector still indicates as other than normal sensitivity, replace the detector.

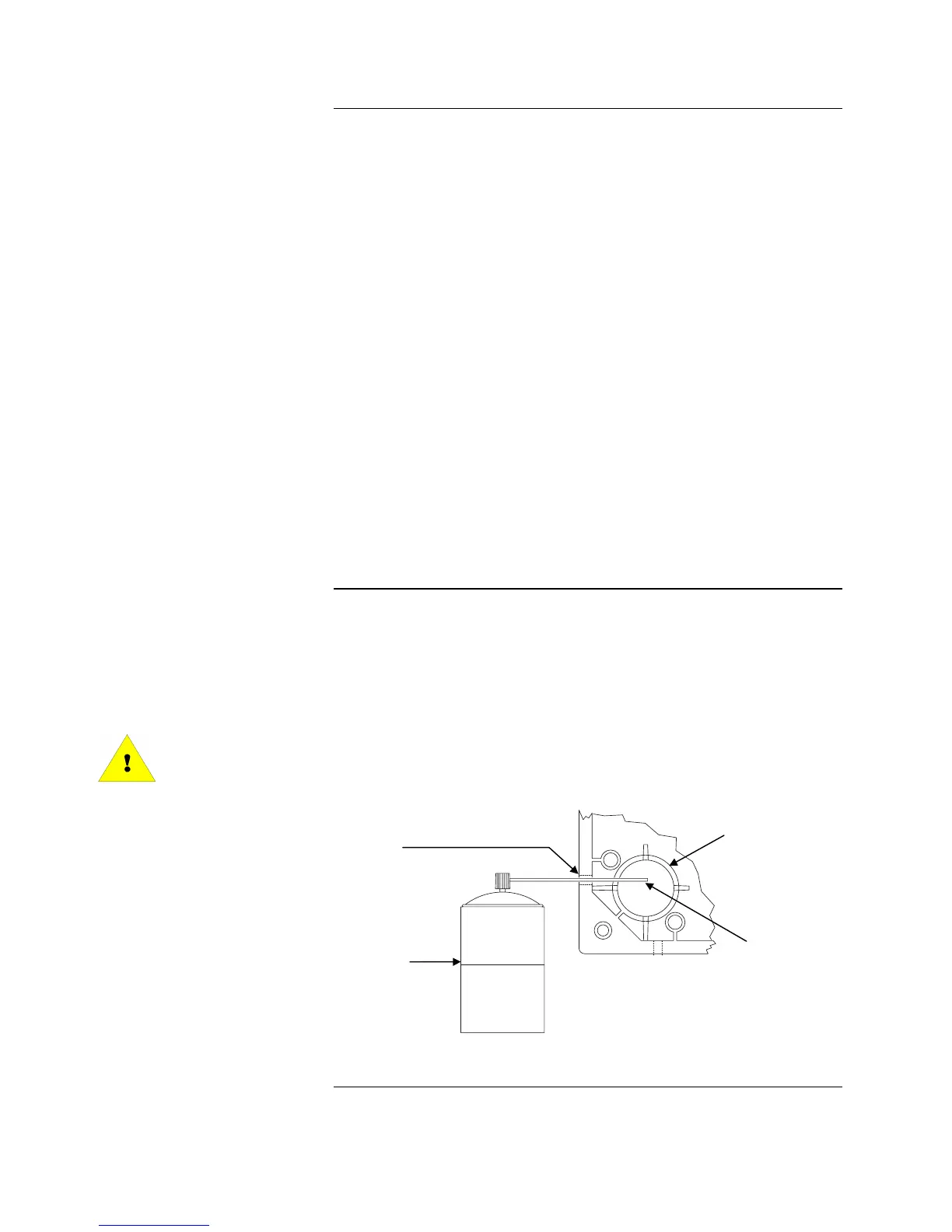

NFPA requires annual testing of the detectors/sensors at their installed location

using smoke or aerosol. With the air handling unit turned on, open one of test

port holes (Figure 1) by removing the red cover on the duct detector/sensor

housing. Using an extended nozzle on the smoke detector aerosol tester

(553-673) spray a 4-second burst of aerosol through the test port but not directly

at the detector/sensor head. The nozzle of the smoke detector aerosol tester

should not extend beyond the inlet tube (see Figure 17). Aerosol is sprayed into

the stream of incoming air and not directly into detector/sensor.

IMPORTANT: Make sure the test port covers are replaced after testing.

Figure 17. Smoke Detector Aerosol Test

Continued on next page

Installation, Continued

Magnetic Test for Detectors

and Sensors (continued)

Preferred Method of Testing

Smoke Detectors/Sensors

SMOKE PORT/AIR

FLOW TES

HOLE

SMOKE DETECTOR

AEROSOL TESTER

(553-673)

RECOMMENDED NOZZLE

LOCATION

(CENTER OF INLET TUBE)

INLET TUBE

Technical Manuals Online! - http://www.tech-man.com

Loading...

Loading...