24

A

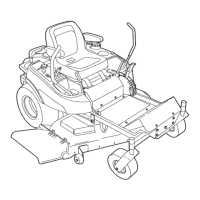

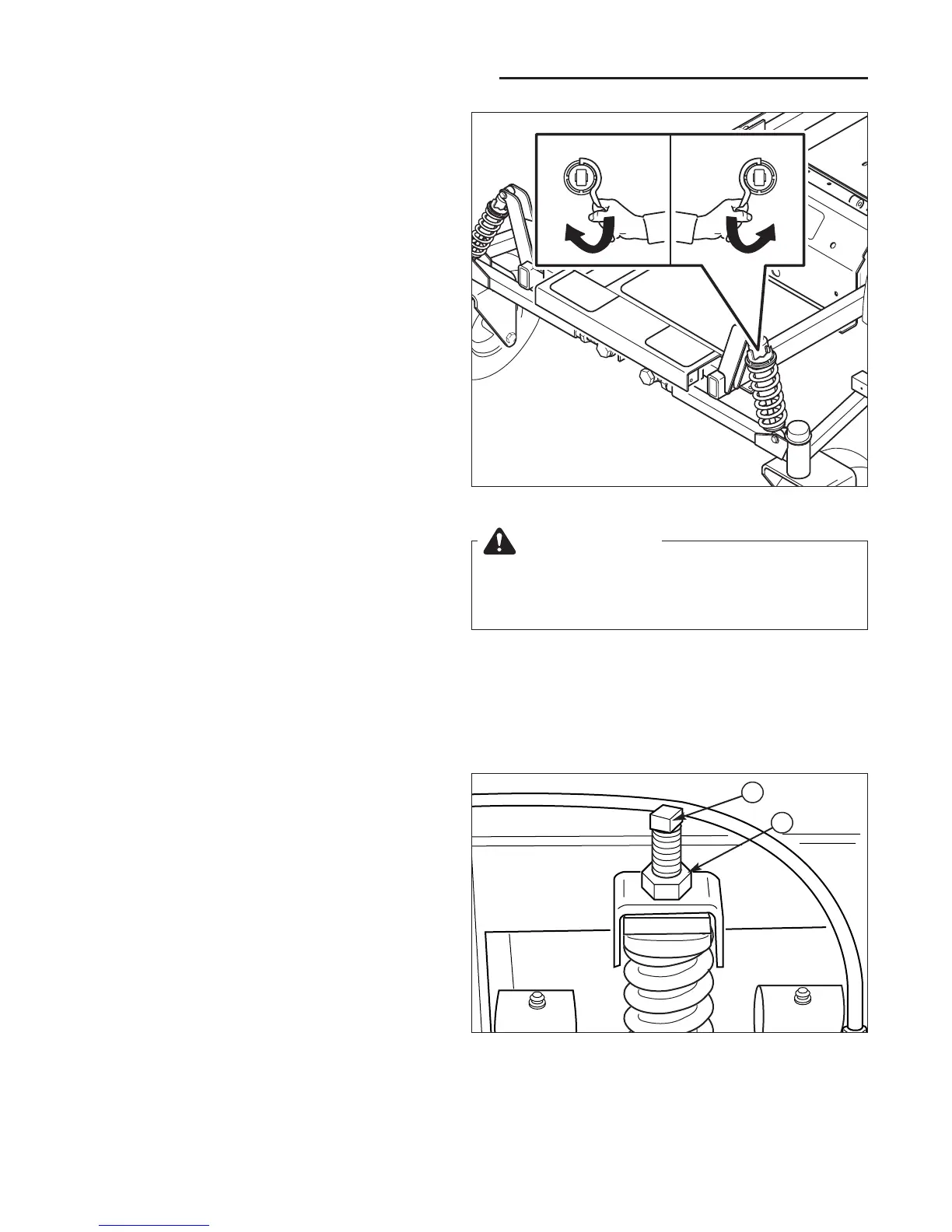

Figure 30. Suspension Height Adjustment

A. Height Adjustment Bolt

B. Jam Nut

B

FRONT SUSPENSION ADJUSTMENT

The shock assembly can be adjusted to vary the amount

of pre-load applied to the springs. This allows the opera-

tor to customize the ride according to operator’s weight

and/or operating conditions.

LESS PRE-LOAD:

• Light operator weight

• Softer, more cushioned ride

• Best for relatively flat terrain

MORE PRE-LOAD:

• Heavy operator weight

• Stiffer, more rigid ride

• Better handling and greater stability on hilly terrain

TO ADJUST THE SPRING PRE-LOAD:

1. Park machine on a flat, level surface. Disengage the

PTO, stop the engine and engage the parking brake.

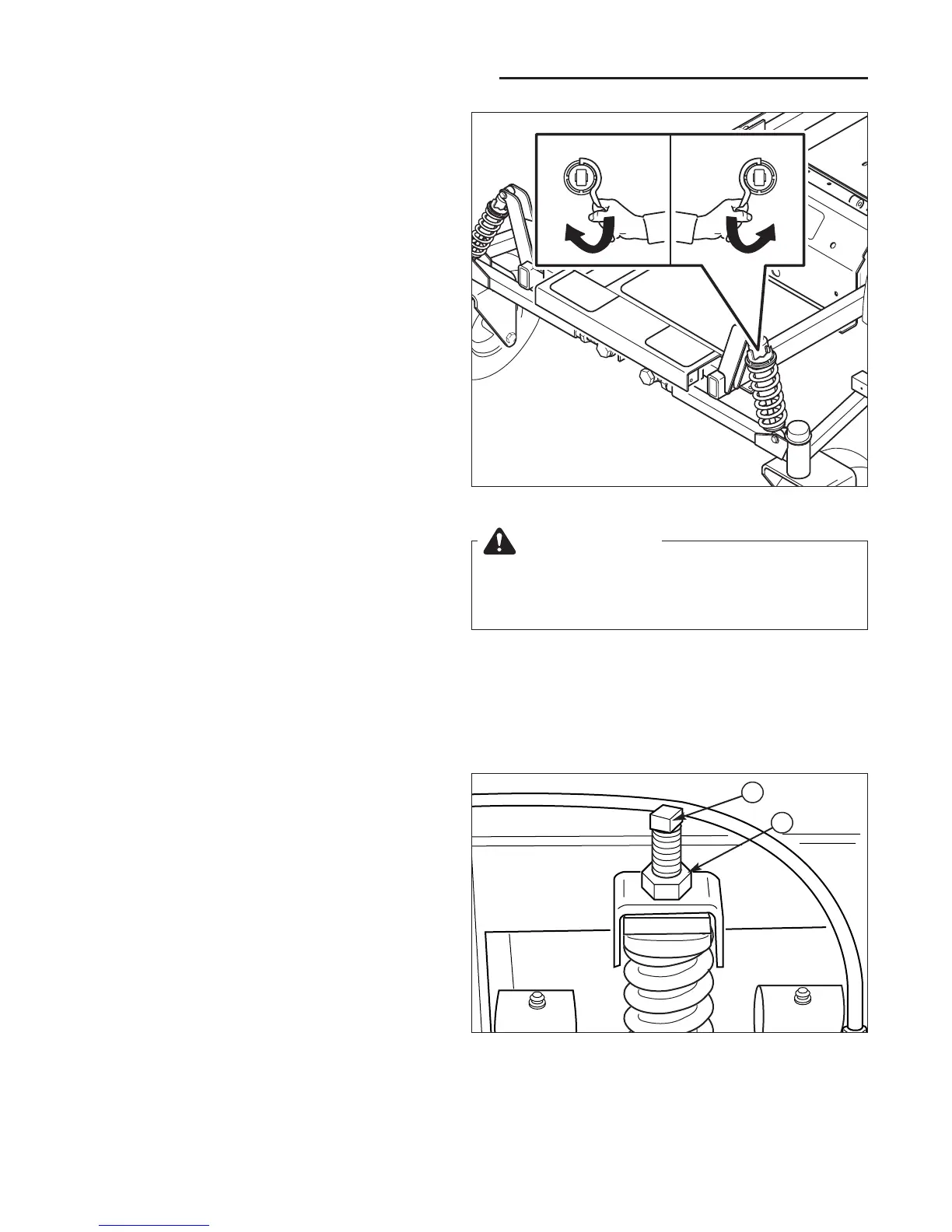

2. See Figure 29. Using the supplied spanner wrench

(p/n 5022853), insert the tip of the wrench into the

notch in the pre-load adjuster. While holding the

wrench in place with one hand, turn CLOCKWISE to

increase the pre-load, turn COUNTER-CLOCKWISE

to decrease the pre-load. Make sure both shocks are

set to the same amount of pre-load.

NOTE: Spanner wrench is located behind the rear seat

cross member, on the left-hand side of the machine.

REAR SUSPENSION ADJUSTMENT

If the rider tilts either side-to-side or front-to-rear, this

adjustment will level the frame with the ground.

Although this adjustment may not be necessary, it may

be required if additional weight (ie. a grass catcher) is

added to the frame or a drive tire is replaced.

NOTE: Perform this adjustment on a hard, level surface

such as a concrete floor.

Measure the distance between the ground and the bot-

tom of the frame, behind the drive tires. This should

measure 9-3/4” (24,7 cm) for both sides for 25hp model;

10-1/4” (26 cm) for 27hp model. If it does not, loosen the

jam nut (B, Figure 30) and turn turn the height adjust-

ment bolt (A) COUNTER-CLOCKWISE to lower the cor-

responding side of the frame, and CLOCKWISE to raise

the frame. Tighten the jam nuts.

Loading...

Loading...