40

Installation and Maintenance

Service Manual

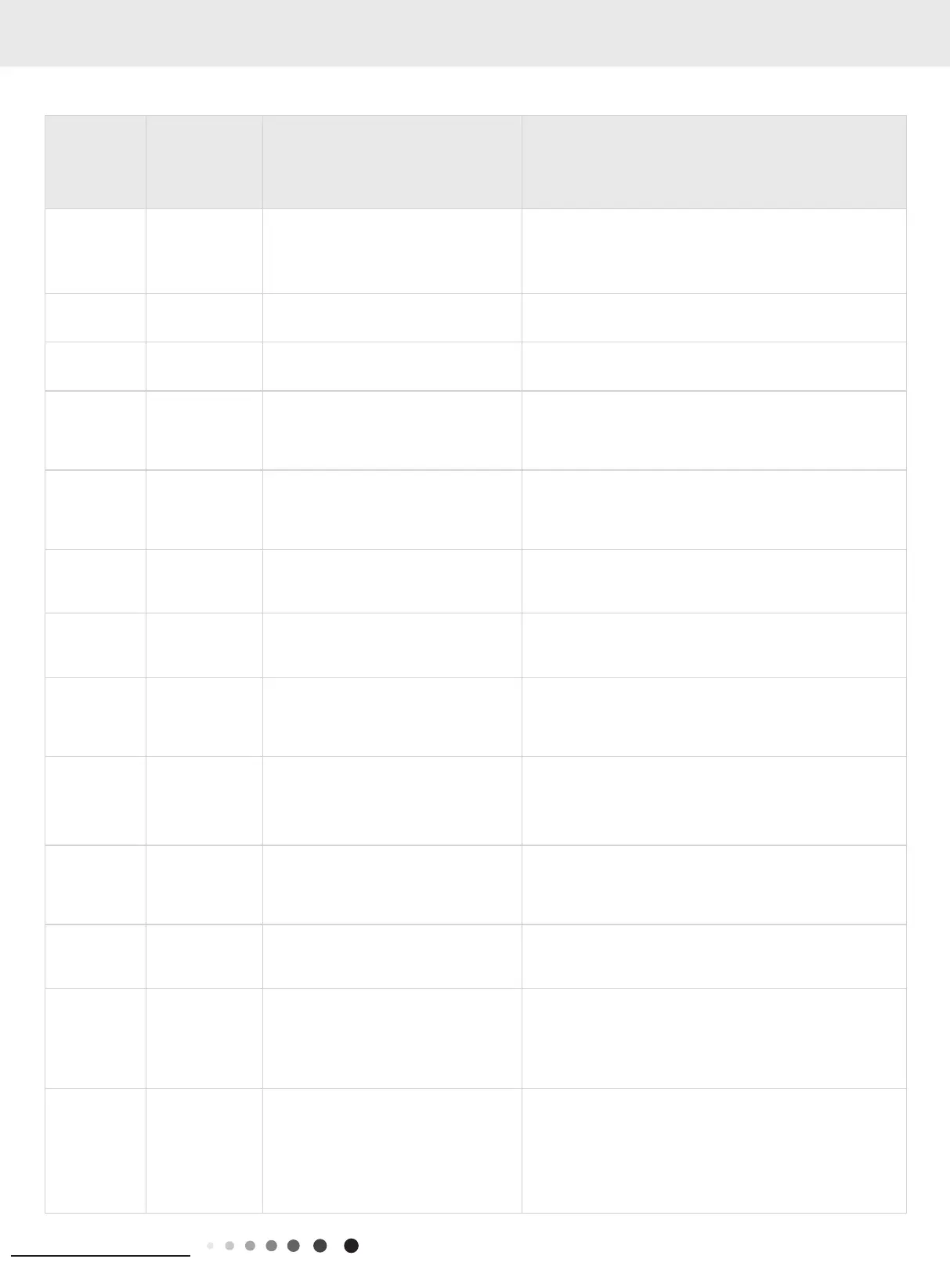

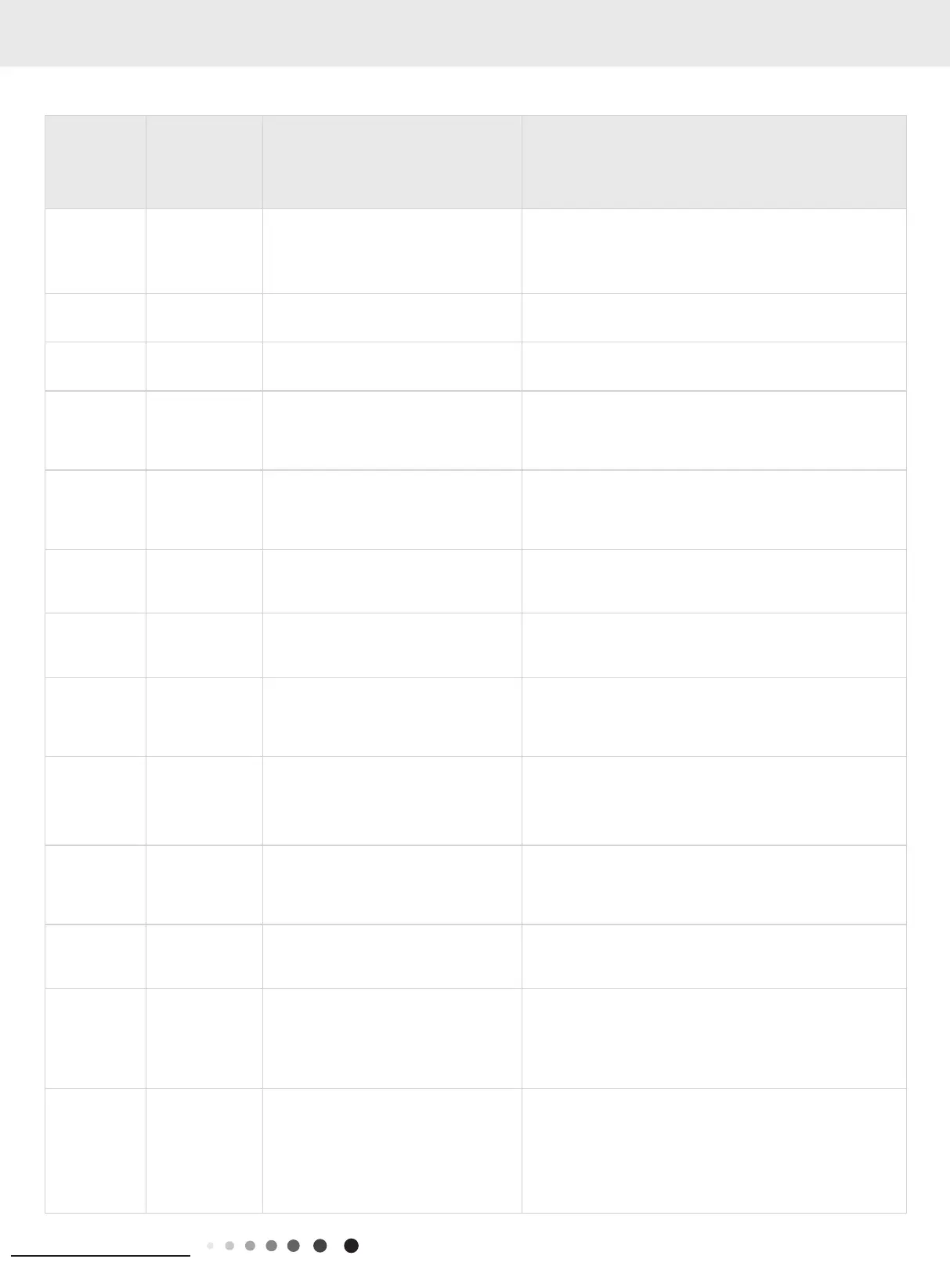

9.1 Error Code List

9. Maintenance

Malfunction

Name

Display Method

of Indoor Unit

(Error Code)

A/C Status

Possible Causes(For specic maintenance

method, please refer to the following procedure of

troubleshooting)

High pressure

protection of

system

E1

During cooling and drying operation,

except indoor fan operates, all loads

stop operation.

During heating operation, the complete

unit stops.

Possible reasons:

1. Refrigerant was superabundant;

2. Poor heat exchange (including lth blockage of heat

exchanger and bad radiating environment ); Ambient

temperature is too high.

Antifreezing

protection for

evaporator

E2 Not the error code. It’s the status code for the operation.

System block

or refrigerant

leakage

E3

The Dual-8 Code Display will show

E3 until the low pressure switch stop

operation.

1.Low-pressure protection

2.Low-pressure protection of system

3.Low-pressure protection of compressor

High discharge

temperature

protection of

compressor

E4

During cooling and drying operation,

compressor and outdoor fan stop while

indoor fan operates. During heating

operation, all loads stop.

Please refer to the malfunction analysis (discharge

protection, overload).

Overcurrent

protection

E5

During cooling and drying operation,

compressor and outdoor fan stop while

indoor fan operates. During heating

operation, all loads stop.

1. Supply voltage is unstable;

2. Supply voltage is too low and load is too high;

3. Evaporator is dirty.

Communi-

cation

Malfunction

E6

During cooling operation, compressor

stops while indoor fan motor operates.

During heating operation, the complete

unit stops.

Refer to the corresponding malfunction analysis.

High

temperature

resistant

protection

E8

During cooling operation: compressor

will stop while indoor fan will operate.

During heating operation, the complete

unit stops.

Refer to the malfunction analysis (overload, high temperature

resistant).

EEPROM

malfunction

EE

During cooling and drying operation,

compressor will stop while indoor fan will

operate;

During heating operation, the complete

unit will stop

Replace outdoor control panel AP1

Limit/decrease

frequency due

to high

temperature of

module

EU

All loads operate normally, while

operation frequency for compressor is

decreased

Discharging after the complete unit is de-energized for

20mins, check whether the thermal grease on IPM Module

of outdoor control panel AP1 is sufcient and whether the

radiator is inserted tightly.

If its no use, please replace control panel AP1.

Malfunction

protection of

jumper cap

C5

Wireless remote receiver and button are

effective, but can not dispose the related

command

1. No jumper cap insert on mainboard.

2. Incorrect insert of jumper cap.

3. Jumper cap damaged.

4. Abnormal detecting circuit of mainboard.

Gathering

refrigerant

F0

When the outdoor unit receive signal of

Gathering refrigerant ,the system will

be forced to run under cooling mode for

gathering refrigerant

Nominal cooling mode

Indoor ambient

temperature

sensor is

open/short

circuited

F1

During cooling and drying operation,

indoor unit operates while other loads

will stop; during heating operation, the

complete unit will stop operation.

1. Loosening or bad contact of indoor ambient temp. sensor

and mainboard terminal.

2. Components in mainboard fell down leads short circuit.

3. Indoor ambient temp. sensor damaged.(check with sensor

resistance value chart)

4. Mainboard damaged.

Indoor

evaporator

temperature

sensor is

open/short

circuited

F2

AC stops operation once reaches the

setting temperature. Cooling, drying:

internal fan motor stops operation while

other loads stop operation; heating: AC

stop operation

1. Loosening or bad contact of Indoor evaporator temp.

sensor and mainboard terminal.

2. Components on the mainboard fall down leads short

circuit.

3. Indoor evaporator temp. sensor damaged.(check temp.

sensor value chart for testing)

4. Mainboard damaged.

Loading...

Loading...