- 12 -

CZ sincro

DG83 D

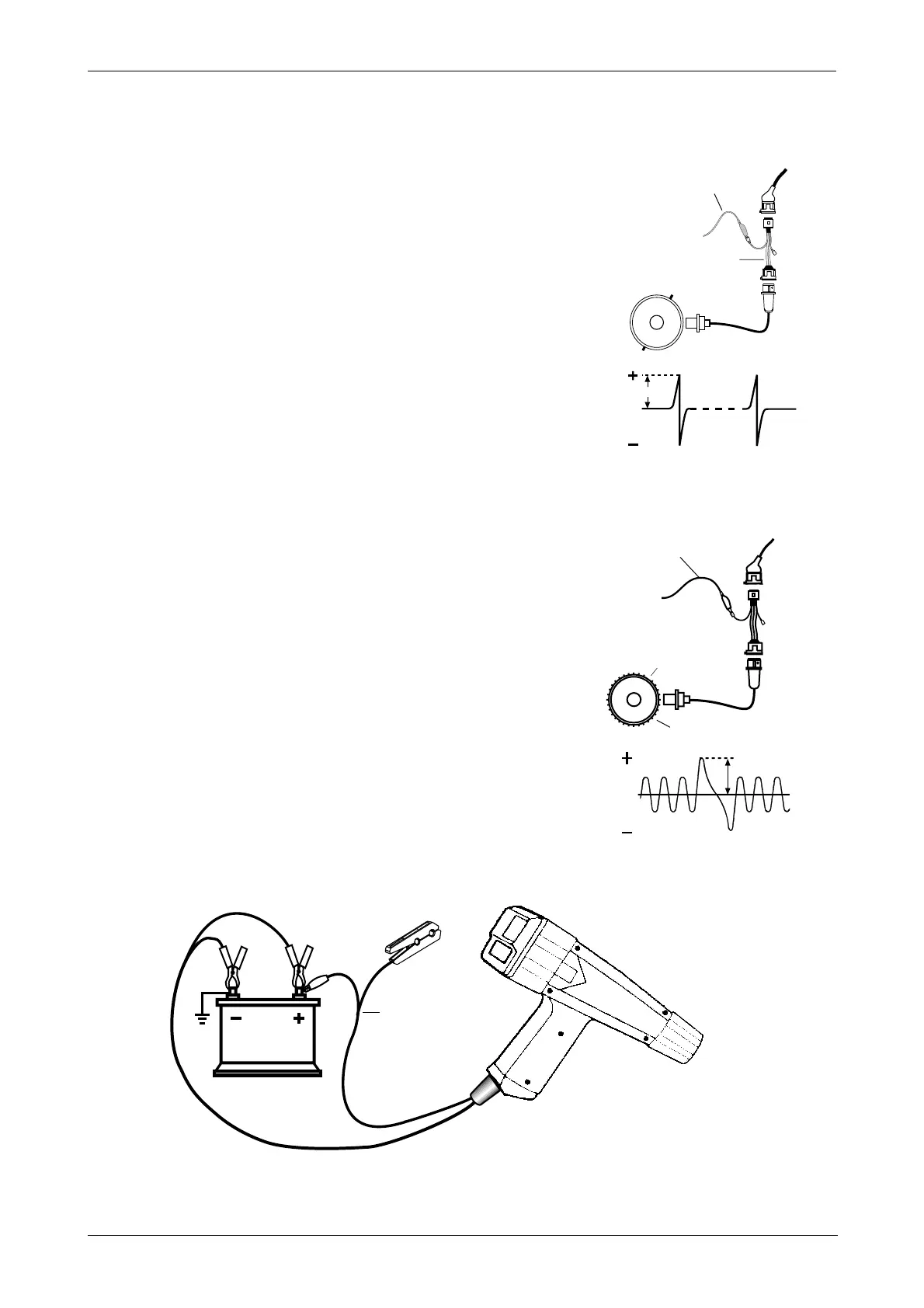

6.3 Peak voltage of reluctance sensors

Peak voltage of reluctance sensors can be found on some types of

ignition modules. Disconnect it from the module and put one end to

ground, connect the other end to the TL 220 cable.

Peak voltage at cranking is about 4 peak Volts and Dwell of 3 ÷ 4

milliseconds. Voltage can decrease if the distance beween the shaft

teeth and the sensor increases.

6.6 Hall effect sensors

Some transistorized ignition modules are driven by a HALL effect sensor

that supplies a square wave voltage to the module, with a fixed or

variable dwell according to the engine speed.

There are three contacts on the sensor’s connector: ground, power supply

and 0 (output signal). For a complete test, check the peak output voltage

and the signal’s Dwell on contact 0 of the connector. Voltage is usually

5 V. In some systems it is 12 V.

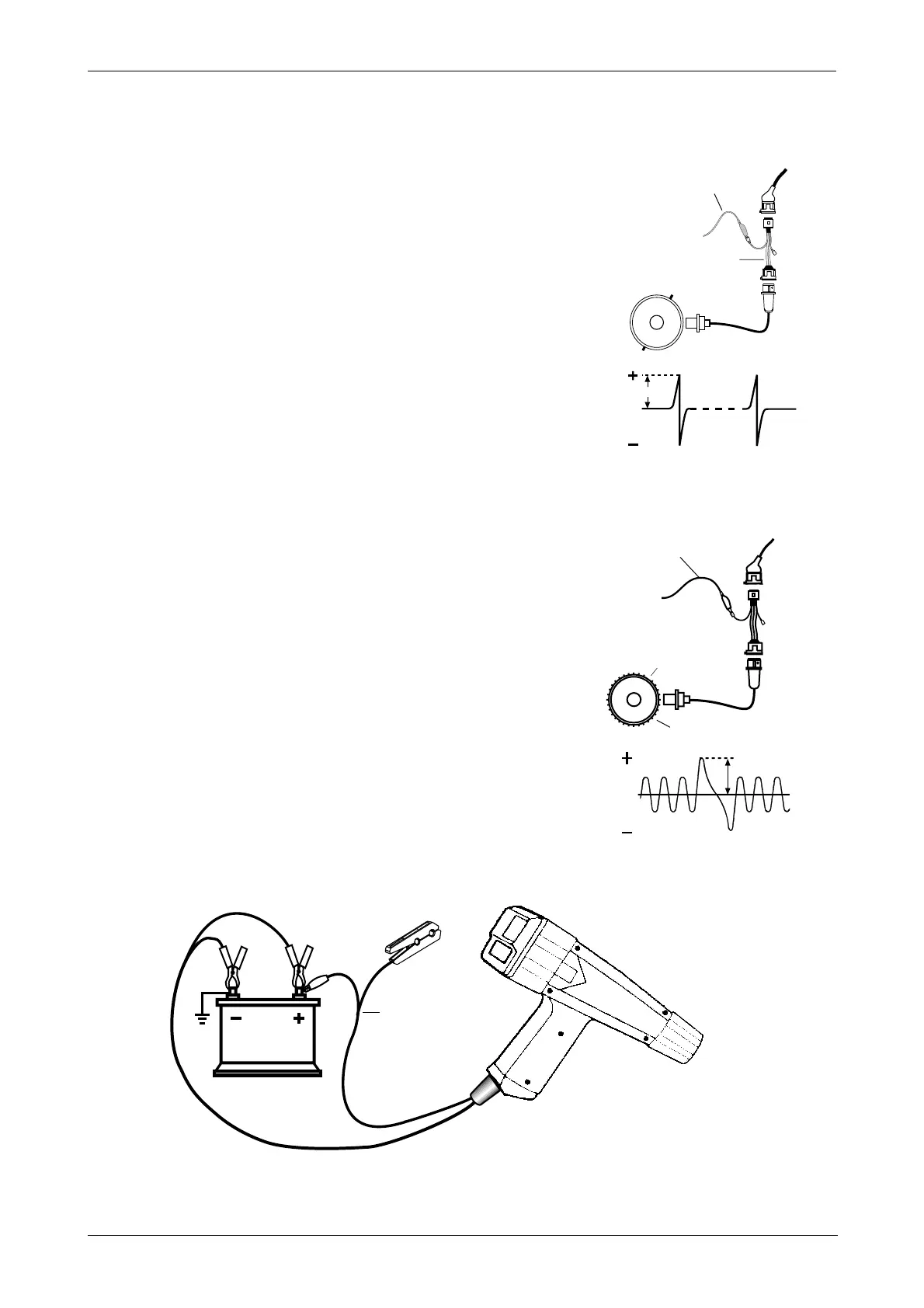

6.7 Voltage drop at cranking

Connect first the Black and then the Red power clip, then connect the

TL 220 cable to the car battery positive pole (Fig. 17). Press key D,

crank the engine and release the key one second after engine dragging.

If the key is pressed too late or after the engine is cranked, voltage

drop at cranking will not be displayed. Voltages below 9,6 Volts can

cause fault codes in the ECU. Check the performance of battery, cranking

motor and alternator’s charging system.

6.8 Battery charging voltage

Bring the engine to about 3000 RPM for a few seconds, battery voltage

will increase to 14.0 Volts. If voltage does not increase, check the voltage

regulator and the alternator.

PEAK VOLTAGE OF

INDUCTIVE SENSORS

Fig. 15

Fig. 17

VOLTAGE DROP AT CRANKING AND BATTERY CHARGING VOLTAGE

TL220 Cable

12 V

Fig. 16

TL 220 cable

Flywheel

Crankshaft

position

peak V

Black

Red

Pulley

AD9-AD10 Marelli-

Bosch adapters

peak V

TL 220 cable

Loading...

Loading...